Detection device and detection method for micro-deformation of crack on surface of rail web

A surface crack and detection device technology, which is applied in the direction of measuring device, optical device, phase influence characteristic measurement, etc., can solve problems such as rail damage, falling blocks, train bumps, etc., and achieve comprehensive analysis, long-distance rapid positioning detection, high Effect of Precision Displacement Measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

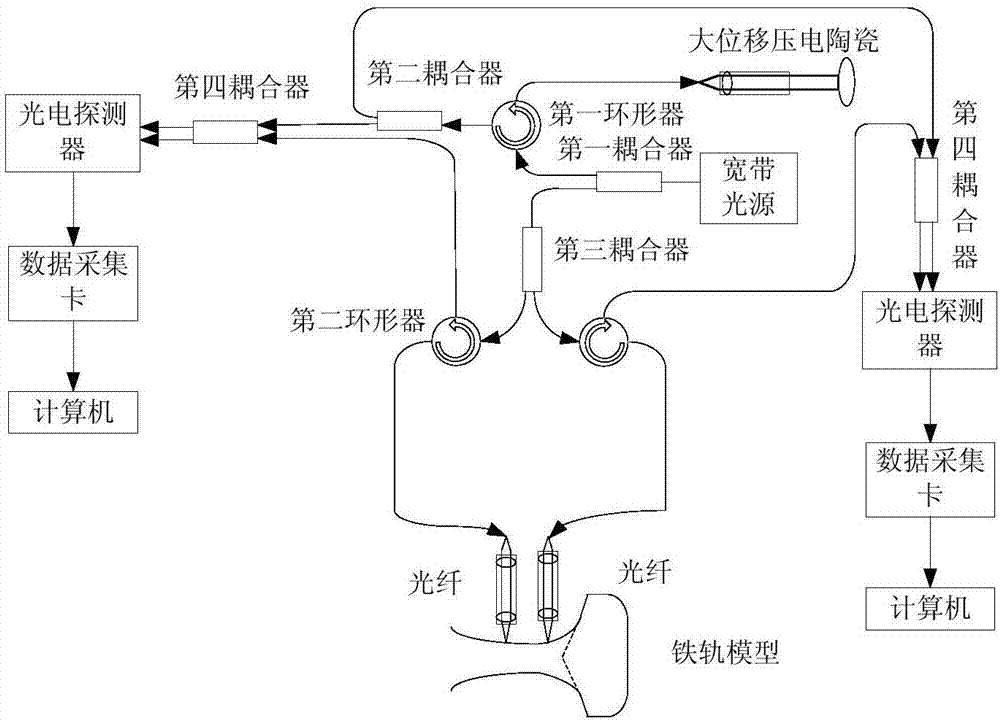

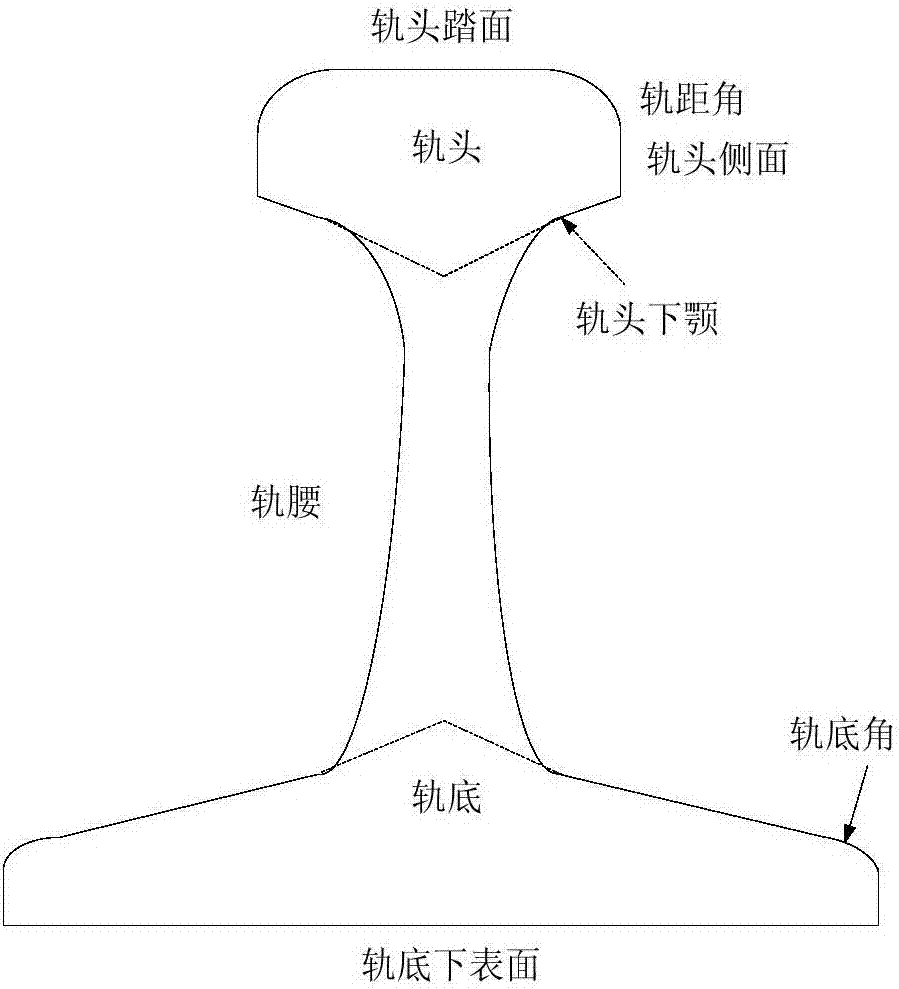

[0034] Such as Figure 1-3 As shown, a rail waist surface crack micro-deformation detection device includes a broadband light source, a first coupler, a reference arm, a first sample arm, a second sample arm, a first signal acquisition circuit and a second signal acquisition circuit;

[0035] The reference arm includes piezoelectric ceramics; the light of the broadband light source is divided into reference light and signal light after passing through the first coupler, and the reference light reaches the piezoelectric ceramics after passing through the first circulator, and is reflected by the surface of the piezoelectric ceramics Returning to the first circulator to emit, the outgoing light is divided into two outgoing reference lights by the second coupler, and the two outgoing reference lights enter the first signal acquisition circuit and the second signal acquisition circuit respectively; the signal light passes through the third coupler After that, it is divided into tw...

Embodiment 2

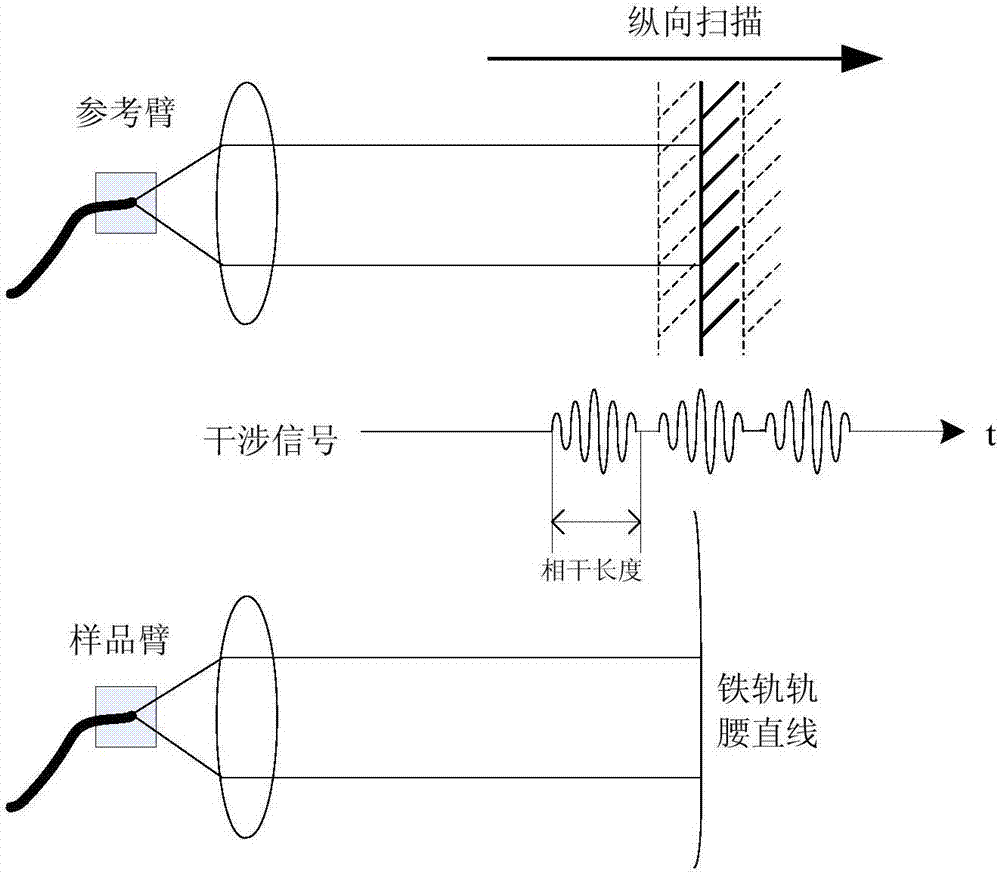

[0045]It can be known from physical optics that in addition to the basic conditions of the same frequency, the same vibration direction, and constant phase difference, the two columns of light waves that interfere must also satisfy the sufficient condition that the optical path difference is within the coherence length of the light source. Low coherence Interference is generated by using this point. The calculation formula of the coherence length of the light source is:

[0046]

[0047] where: λ 0 Represents the central wavelength of the light source, Δλ represents the wavelength bandwidth; the coherence length represents the minimum accuracy of measuring the deformation of the rail waist.

[0048] It can be seen from the above formula that the present invention uses low-coherence signals for detection, which can achieve higher-precision displacement measurement (that is, microscopic rail deformation can be measured), so it is easier to detect early micro-cracks, and can e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com