Substrate cleaning apparatus and substrate cleaning method

A technology for cleaning devices and substrates, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of basement membrane erosion and collapse of substrates, and achieve the effect of suppressing pattern collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

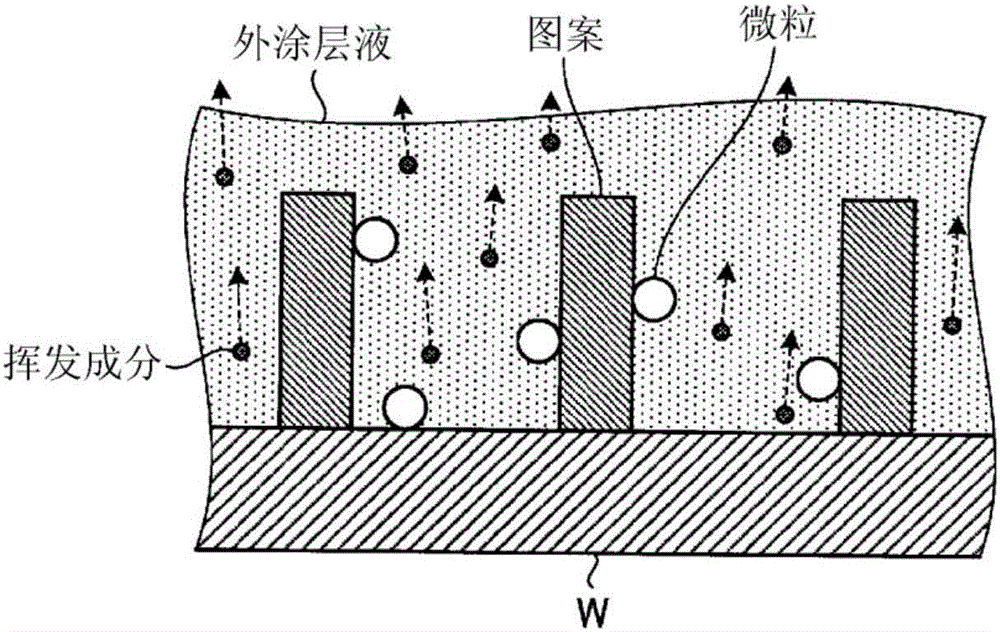

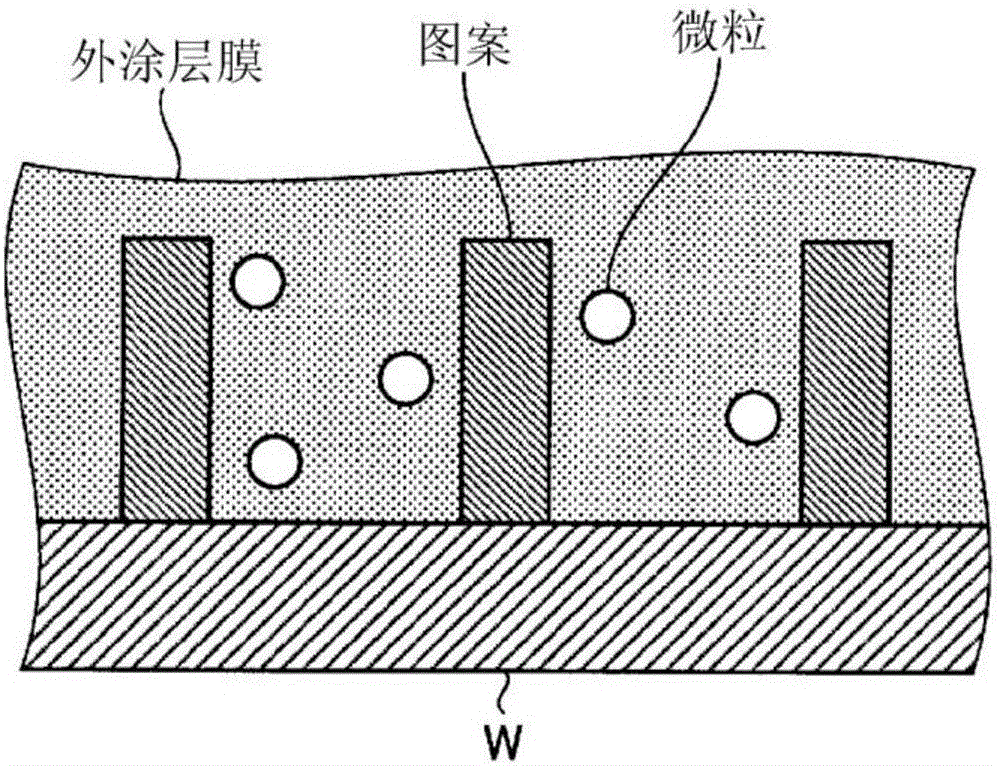

[0039] Outline structure of substrate cleaning system

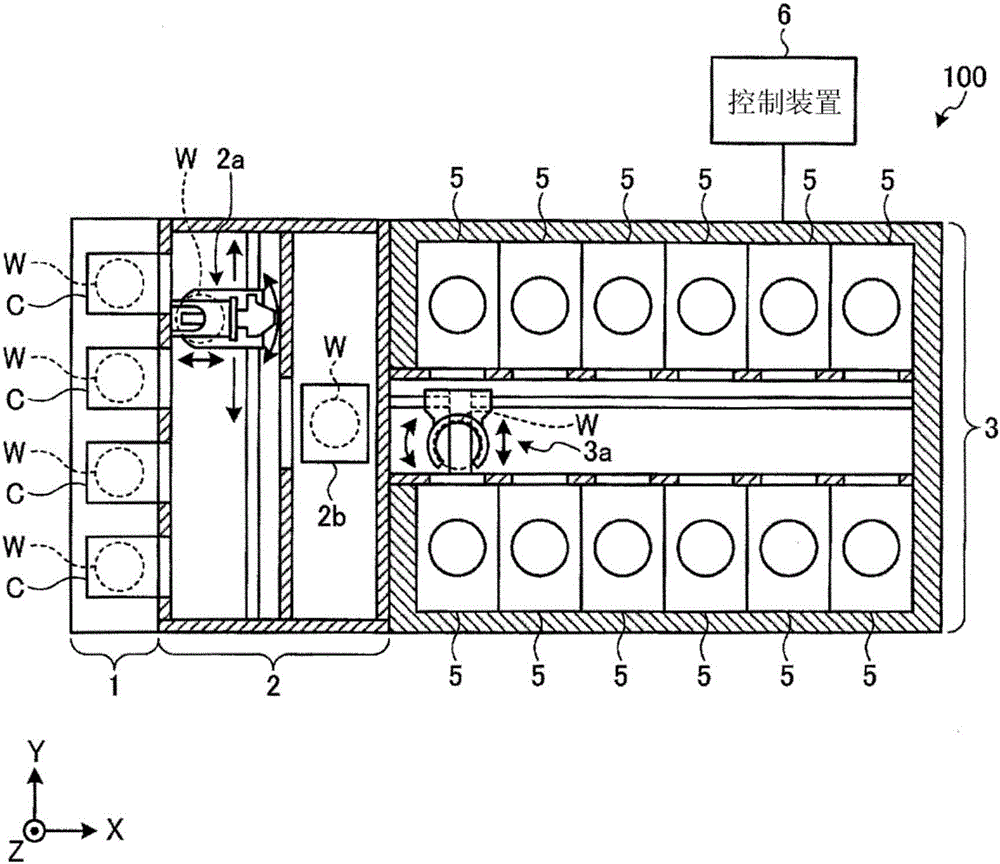

[0040] First, use figure 1 A schematic configuration of the substrate cleaning system according to the first embodiment will be described. figure 1 It is a figure which shows the schematic structure of the board|substrate cleaning system of 1st Embodiment.

[0041] In addition, hereinafter, in order to clarify the positional relationship, the mutually orthogonal X-axis, Y-axis, and Z-axis are defined, and the positive direction of the Z-axis is defined as a vertically upward direction. In addition, hereinafter, the side in the negative direction of the X-axis is defined as the front of the substrate cleaning system, and the side in the positive direction of the X-axis is defined as the rear of the substrate cleaning system.

[0042] Such as figure 1 As shown, the substrate cleaning system 100 includes an input and output station 1 , a delivery station 2 and a processing station 3 . The input / output station 1 , trans...

no. 2 Embodiment approach

[0130] In addition, in the above-mentioned first embodiment, volatilization of volatile components contained in the overcoat liquid is accelerated by heating the overcoat liquid or reducing the humidity in the chamber 10 or making the chamber 10 in a decompressed state. However, the volatilization acceleration treatment is not limited to the treatment described in the first embodiment. Below, use Figure 6 Another example of volatilization promotion treatment will be described. Figure 6 It is a schematic diagram showing the structure of the substrate cleaning apparatus of the second embodiment. In addition, in the following description, the same code|symbol as the part which was already demonstrated is attached|subjected to the part which was already demonstrated, and redundant description is abbreviate|omitted.

[0131] A substrate cleaning apparatus 5A of the second embodiment includes an ultraviolet irradiation unit 60 in addition to each component included in the substr...

no. 3 Embodiment approach

[0135] The structure of the substrate cleaning apparatus is not limited to the structures shown in the above-mentioned embodiments. Therefore, the following, using Figure 7 Another configuration of the substrate cleaning apparatus will be described. Figure 7 It is a schematic diagram showing the structure of the substrate cleaning apparatus of the third embodiment. In addition, in the following description, the same code|symbol as the part which was already demonstrated is attached|subjected to the part which was already demonstrated, and redundant description is abbreviate|omitted.

[0136] Such as Figure 7 As shown, the substrate cleaning apparatus 5B of the third embodiment includes a chamber 10 ′, a substrate holding unit 20 ′, and a recovery cup 40 ′ instead of the chamber 10 and the substrate holding unit 20 of the substrate cleaning apparatus 5 of the first embodiment. And recovery cup 40. Furthermore, the substrate cleaning apparatus 5B includes a top plate 213 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com