Direct current cable accessory silicon rubber insulation surface layer molecular structure regulation and control device and method

A silicone rubber insulation, DC cable technology, applied in the direction of conductor/cable insulation, etc., can solve the problems of affecting the dielectric, breakdown and flashover performance of silicone rubber insulation, changing the insulation structure and electric field distribution, etc., to achieve the reaction process. Stable and controllable, simple production process and process, inhibiting the effect of injection and accumulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings:

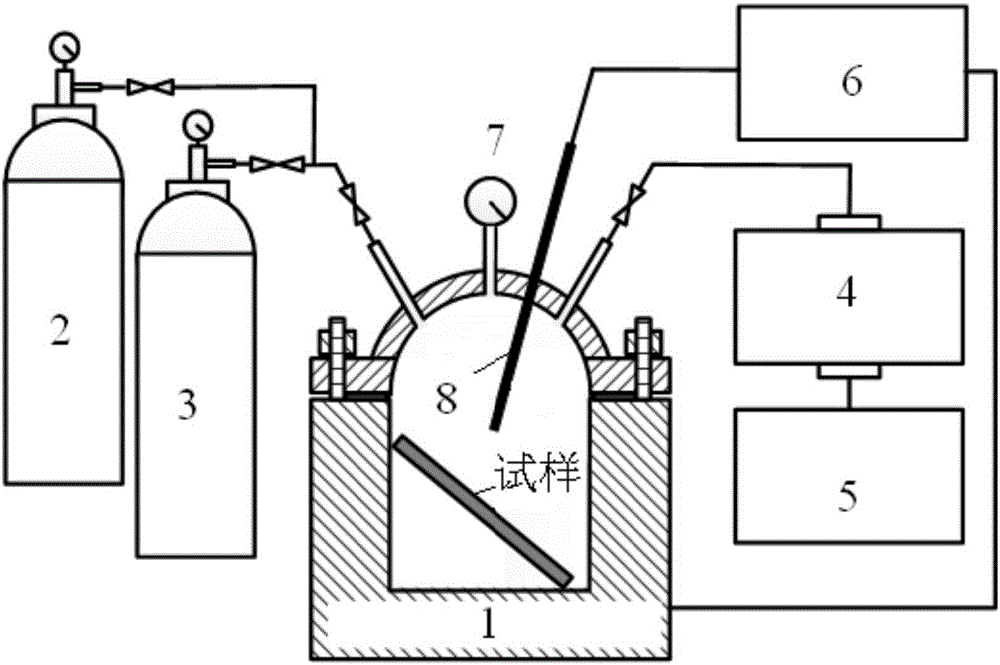

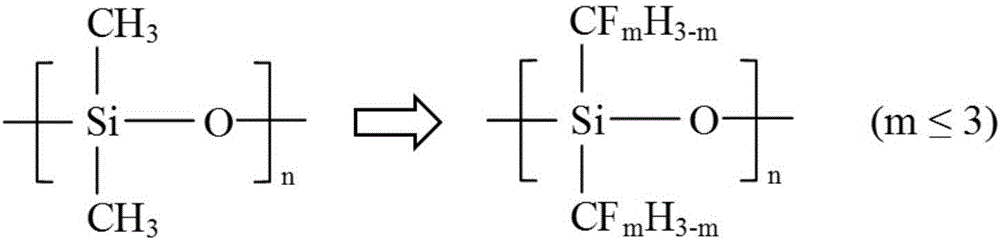

[0026] Since the surface molecule of silicone rubber contains a large number of methyl groups, the active properties of fluorine gas are used to control the surface molecular structure of silicone rubber, so that the C-H bond is replaced by the C-F bond, thereby in the surface molecule of the silicone rubber The introduction of a large number of fluorine-containing functional groups, the control process of the chemical formula of the surface layer of silicone rubber is as follows: figure 2 Shown. Because fluorine gas is highly corrosive, in order to ensure the safety of personnel in the process of surface molecular structure adjustment, a set of DC cable accessories silicone rubber reinforced insulation surface molecular structure adjustment device has been designed, such as figure 1 As shown, it includes a reaction vessel 1 for placing samples. The reaction vessel 1 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com