Electrical isolation device and manufacturing method thereof

A production method and electrical isolation technology are applied in the fields of electrophoresis and chromatographic analysis to achieve the effects of simple method, long life and avoiding short life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, the method comprises the following steps:

[0055] 1. Capillary pretreatment:

[0056] In order to activate the silanol in the capillary, the capillary was first rinsed with deionized water for 30 min, then the capillary was rinsed with 1 M NaOH solution for 3 h, and finally the capillary was rinsed with deionized water for 30 min.

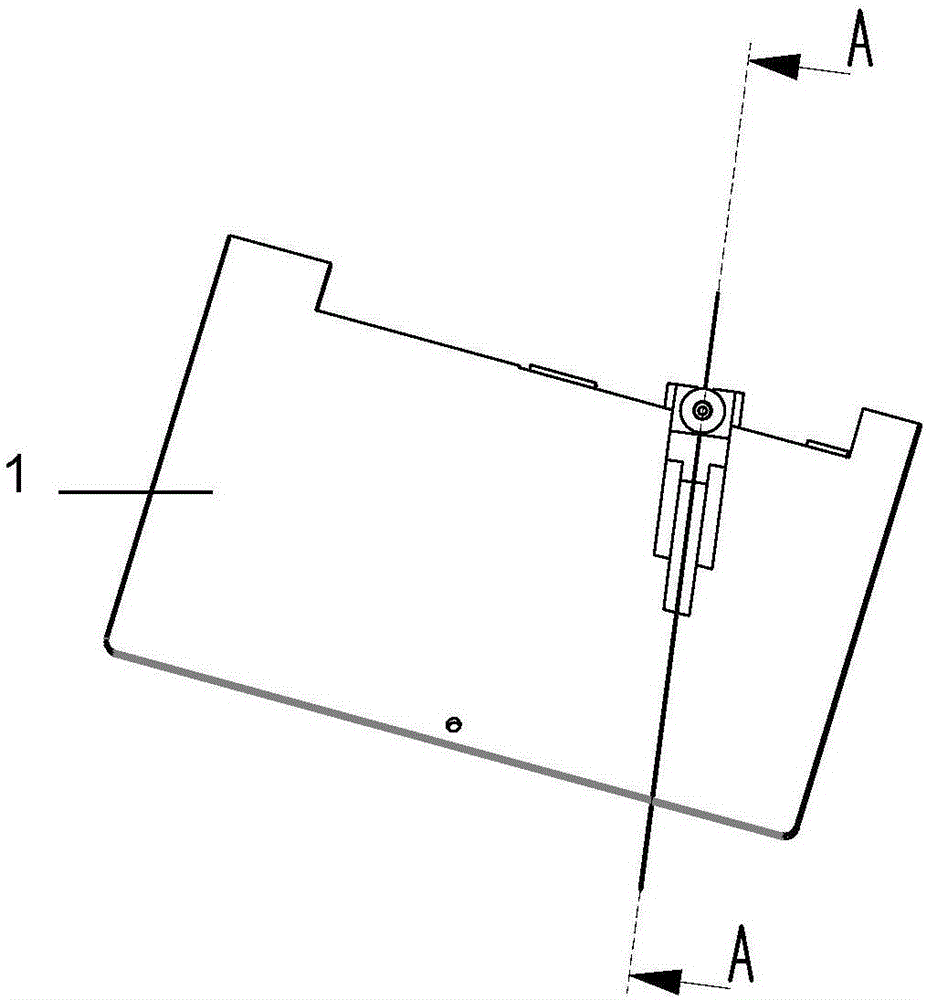

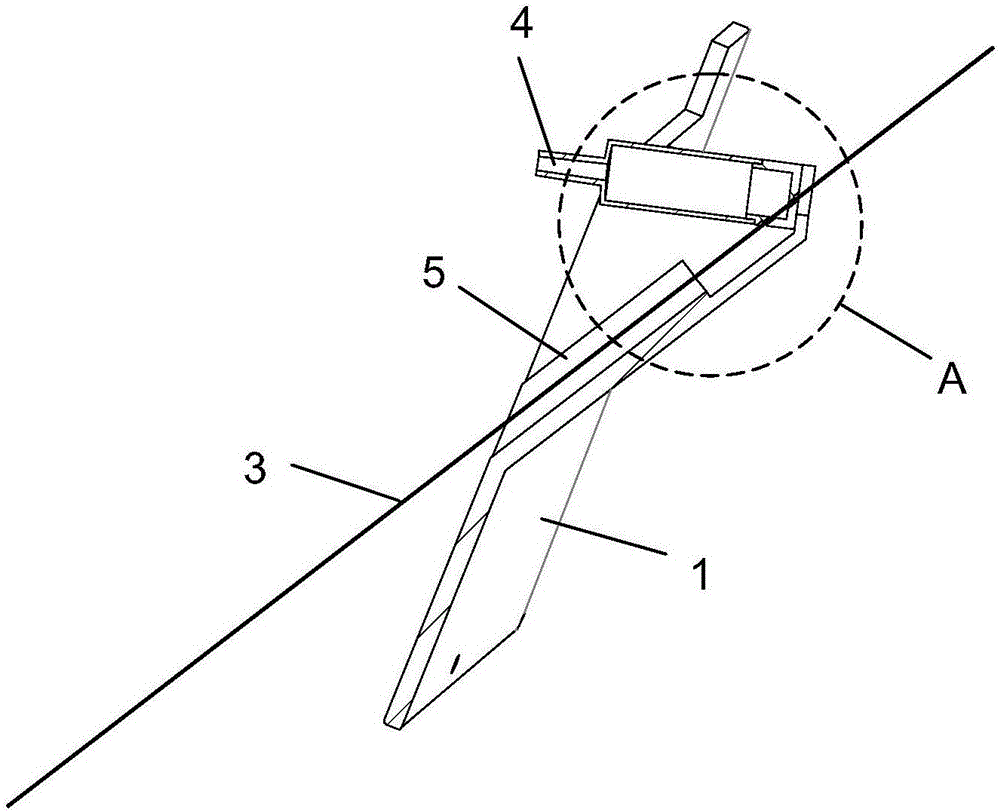

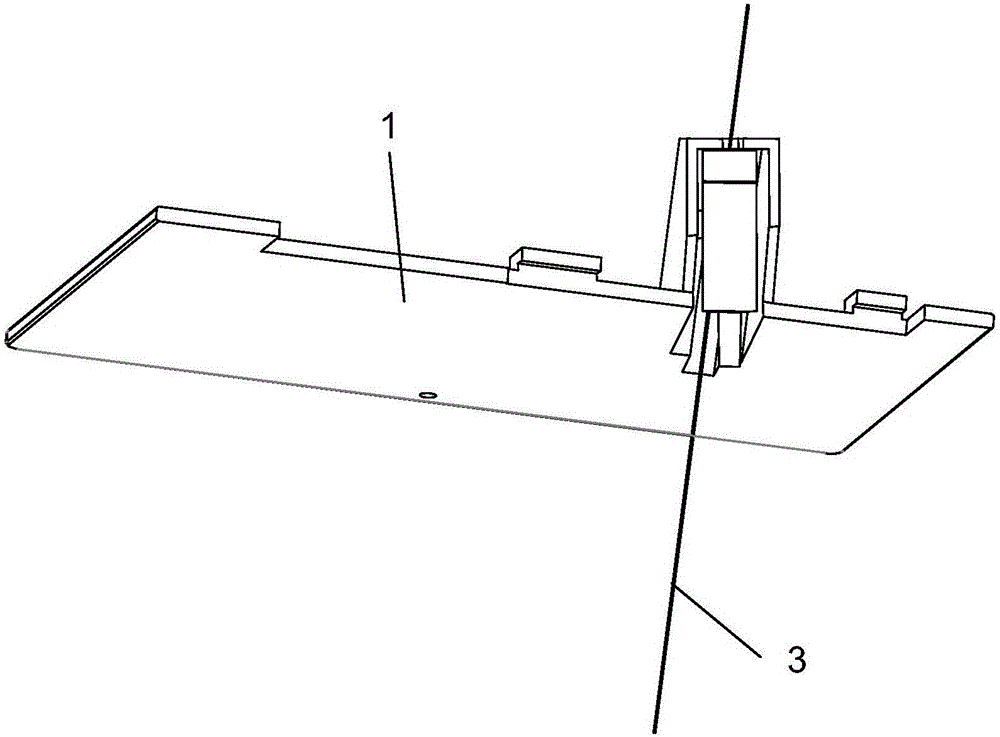

[0057] 2. Installed in the corrosion device:

[0058] Take a 50cm-long pretreated capillary with an inner diameter of 75μm and install it in the corrosion device of the electrical isolation device.

[0059] Three: rust process

[0060] (1) Pour into 2ml, 1% hydrochloric acid;

[0061] (2) Closed corrosion device to avoid acid volatilization and water absorption;

[0062] (3) Corrosion at room temperature for 6 hours;

[0063] (4) Turn on the corrosion device, and rinse the corrosion surface of the capillary with deionized water for 30 minutes;

[0064] (5) Dry in a vacuum oven at 50 degrees.

[0065] Four: Installation ...

Embodiment 2

[0069] The method includes the following steps:

[0070] 1. Capillary pretreatment:

[0071] In order to activate the silanol in the capillary, first rinse the inner wall of the capillary with demethanol for 20 minutes, rinse the capillary with deionized water for 10 minutes, then rinse the capillary with 1M NaOH solution for 3 hours, and finally rinse the capillary with deionized water for 30 minutes.

[0072] 2. Installed in the corrosion device:

[0073] Take a 50cm-long pretreated capillary with an inner diameter of 75μm and install it in the corrosion device of the electrical isolation device.

[0074] Three: rust process

[0075] (1) pour into 2ml, 5% sulfuric acid;

[0076] (2) Closed corrosion device to avoid acid volatilization and water absorption;

[0077] (3) Corrosion at room temperature for 3 hours;

[0078] (4) Turn on the corrosion device, and rinse the corrosion surface of the capillary with deionized water for 30 minutes;

[0079] (5) Dry in a vacuum oven...

Embodiment 3

[0083] The method includes the following steps:

[0084] 1. Capillary pretreatment:

[0085] In order to activate the silanol in the capillary, wash the inner wall of the capillary with methanol for 40 minutes, deionized water for 20 minutes, 1M NaOH solution for 3 hours, deionized water for 20 minutes, 1M HCl for 20 minutes, and finally deionized water. Capillary 30min.

[0086] 2. Installed in the corrosion device:

[0087] Take a 60cm-long pretreated 75μm inner diameter capillary and install it in the corrosion device of the electrical isolation device;

[0088] Three: rust process

[0089] (1) pour into 2ml, 3% hydrofluoric acid;

[0090] (2) Closed corrosion device to avoid acid volatilization and water absorption;

[0091] (3) Corrosion at 30°C for 3.5 hours;

[0092] (4) Open the isolation device and rinse the corroded surface of the capillary with deionized water for 50 minutes;

[0093] (5) Dry in a vacuum oven at 70 degrees.

[0094] Four: Installation proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com