Motor carbon brush sintering furnace

A sintering furnace and carbon brush technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of waste heat, atmospheric environment impact, reduction of furnace sintering temperature, etc., to reduce pollution, ensure sintering quality, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

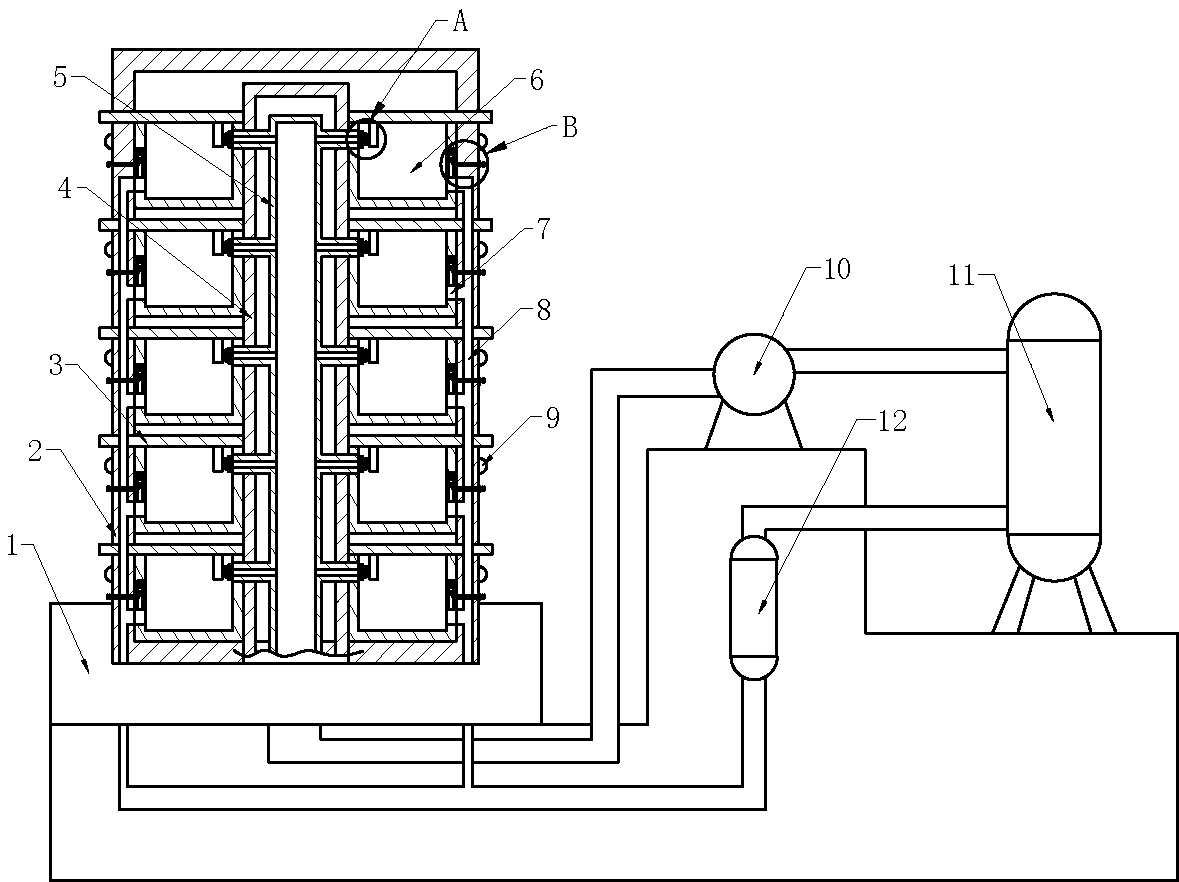

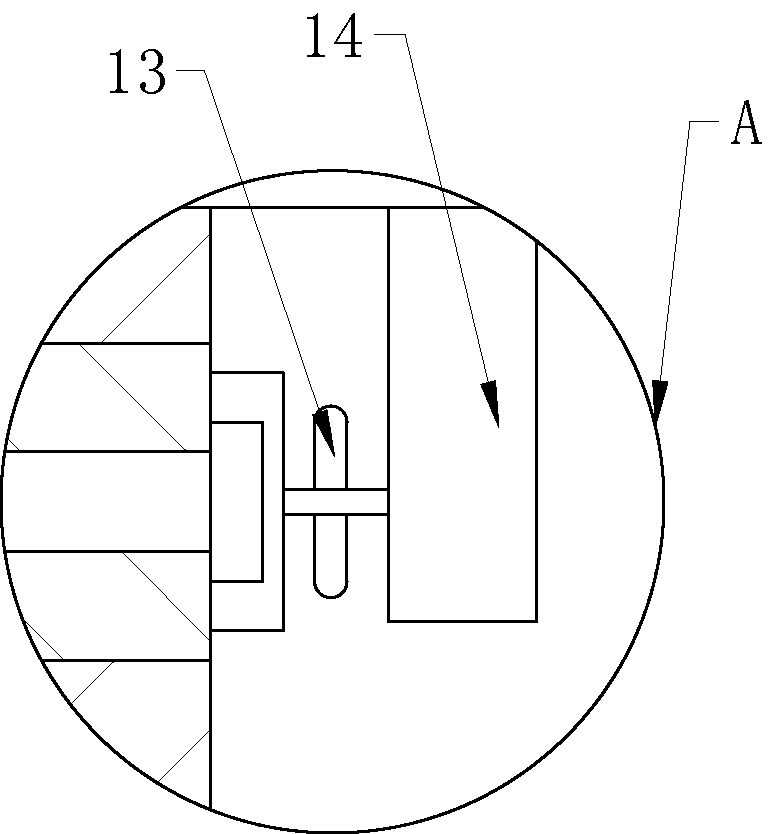

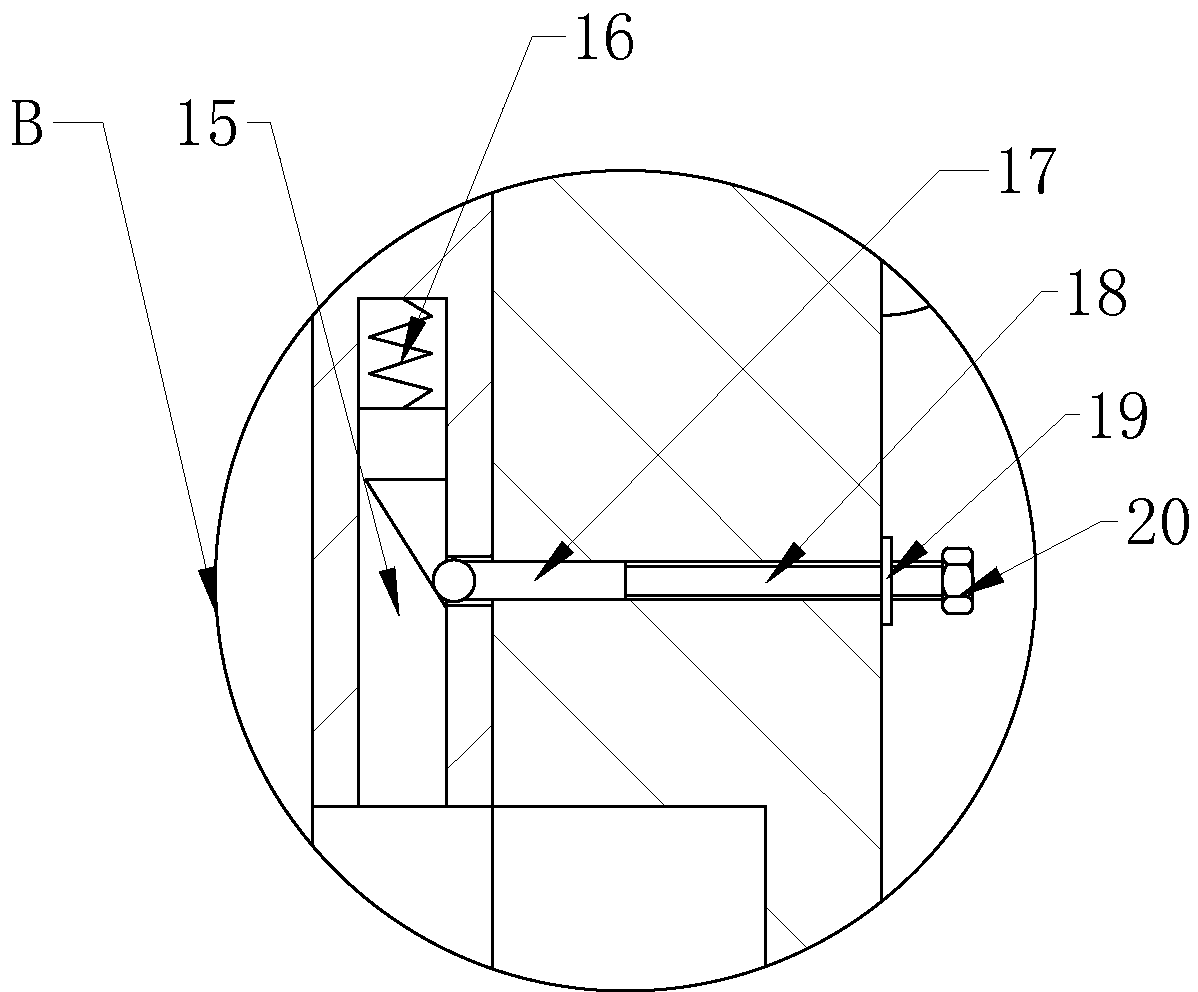

[0022] Example: such as Figure 1-3 As shown, the motor carbon brush sintering furnace includes a base 1 and a furnace body 2. The furnace body 2 is screwed on the base 1 through a threaded rod. There is a cavity in the furnace body 2, and vertical equidistant holes are installed on both sides of the cavity. Arranged sintering pots 6, the top of the sintering pots 6 is slidingly connected with a cover 3, the left end or right end of the cover 3 protrudes from the furnace body 2, and the furnace body 2 between the two rows of sintering pots 6 is welded for heating the sintering pots 6 The electric heating tube 4 is equipped with an electrically connected power supply and buttons in the base 1, and the electric heating tube 4 is electrically connected to the power supply and the buttons. The electric heating tube 4 is provided with a vent pipe 5, and the vent pipe 5 is welded on the furnace body 2. , the ventilation pipe 5 communicates with the upper part of each sintering pot 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com