Heat-insulating, high-temperature and aging-resistant vibration-damping seal for automobile lamps and its preparation process

A technology for automotive lamps and high temperature resistance, which is applied to the sealing of engines, lighting and heating equipment, components of lighting devices, etc. Problems such as radiation and gasket resilience are difficult to maintain for a long time, so as to achieve the effect of reducing the number of car light maintenance, more frequent car light maintenance, and preventing stress relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A preparation process of a heat-insulating, high-temperature and aging-resistant vibration-damping seal for automobile lamps, comprising the following steps:

[0034] 1) Spray and clean the surface of EPDM rubber closed-cell foam sheet, and dry it at 70°C;

[0035] 2) Corona polarization on the surface of EPDM rubber closed-cell foam sheet;

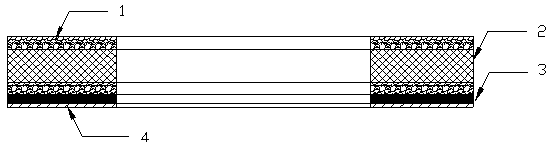

[0036] 3) Airlessly spray a layer of expanded perlite micro-powder heat-resistant heat-resistant paint with a thickness of 0.2mm on the upper and lower surfaces of the EPDM rubber closed-cell foam sheet, and dry at 75°C for 30 minutes to dry the heat-insulated paint ;

[0037] 4) If it is necessary to thicken the coating, repeat step 3) several times after the coating is dried until the required thickness is reached;

[0038] 5) Coat the back glue on the thermal insulation paint, and cover the back glue with silicone oil paper;

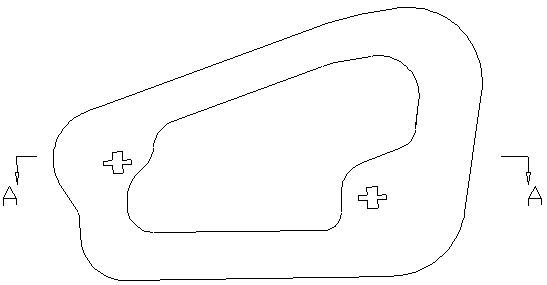

[0039] 6) Die-cutting, that is, the preparation of the seal is completed.

Embodiment 2

[0040] Embodiment 2: A preparation process of a heat-insulating, high-temperature and aging-resistant vibration-damping seal for automobile lamps, comprising the following steps:

[0041] 1) Spray and clean the surface of the EPDM rubber closed-cell foam sheet, and dry it at 75°C;

[0042] 2) Corona polarization on the surface of EPDM rubber closed-cell foam sheet;

[0043] 3) Airlessly spray a layer of expanded perlite micro-powder heat-resistant heat-resistant paint with a thickness of less than 0.35mm on the upper and lower surfaces of the EPDM rubber closed-cell foam sheet, and dry it at 80°C for 35 minutes to dry the heat-insulated paint. Dry;

[0044] 4) If it is necessary to thicken the coating, repeat step 3) several times after the coating is dried until the required thickness is reached;

[0045] 5) Coat the back glue on the thermal insulation paint, and cover the back glue with silicone oil paper;

[0046] 6) Die-cutting, that is, the preparation of the seal is c...

Embodiment 3

[0047] Embodiment 3: A preparation process of a heat-insulating, high-temperature and aging-resistant vibration-damping seal for automobile lamps, comprising the following steps:

[0048] 1) Spray and clean the surface of EPDM rubber closed-cell foam sheet, and dry it at 80°C;

[0049] 2) Corona polarization on the surface of EPDM rubber closed-cell foam sheet;

[0050]3) Airlessly spray a layer of expanded perlite micro-powder heat-resistant heat-resistant paint with a thickness of 0.4mm on the upper and lower surfaces of the EPDM rubber closed-cell foam sheet, and dry it at 83°C for 38 minutes to dry the heat-insulated paint ;

[0051] 4) If it is necessary to thicken the coating, repeat step 3) several times after the coating is dried until the required thickness is reached;

[0052] 5) Coat the back glue on the thermal insulation paint, and cover the back glue with silicone oil paper;

[0053] 6) Die-cutting, that is, the preparation of the seal is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com