Ion exchange glass generation device

A generation device and ion exchange technology, which is applied in the field of glass materials, can solve the problems of low ion exchange efficiency and inability to effectively control the ion exchange depth, and achieve the effects of shortening exchange time, reducing process costs, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

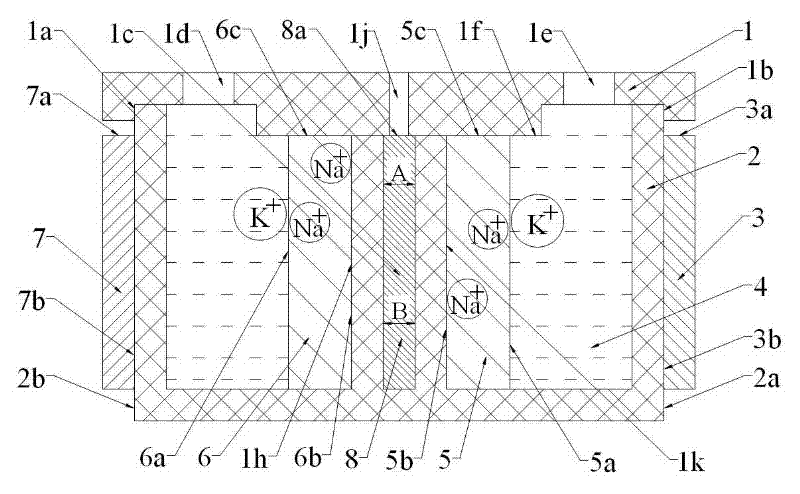

[0017] figure 1 Is a cross-sectional view of the ion exchange glass production device of the present invention, in figure 1 In the middle, the right end surface 7b of the left electrode 7 is bonded to the outer left end surface 2b of the container 2, the left end surface 3b of the right electrode 3 is bonded to the outer right end surface 2a of the container 2, and the middle electrode 8 is placed in the middle groove of the container 2; Glass 6 and ion exchange medium 4 are located in the left cavity of container 2, and glass 5 and ion exchange medium 4 are located in the right cavity of container 2. At the same time, glass 5 and glass 6 are immersed in ion exchange medium 4; cover plate 1 passes through its left The side inner end surface 1a and the right inner end surface 1b are positioned at the upper end of the container 2. Specifically, the lower end face 1f of the cover plate 1 is in close contact with the upper end face 6c of the glass 6, the upper end face 5c of the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com