Worm gear and worm set with center distance adjustment and clearance elimination, brake and steering system

A worm gear, center distance technology, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problem of inconsistent transmission efficiency, improve transmission resistance and transmission efficiency. The effect of meshing clearance and stable transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

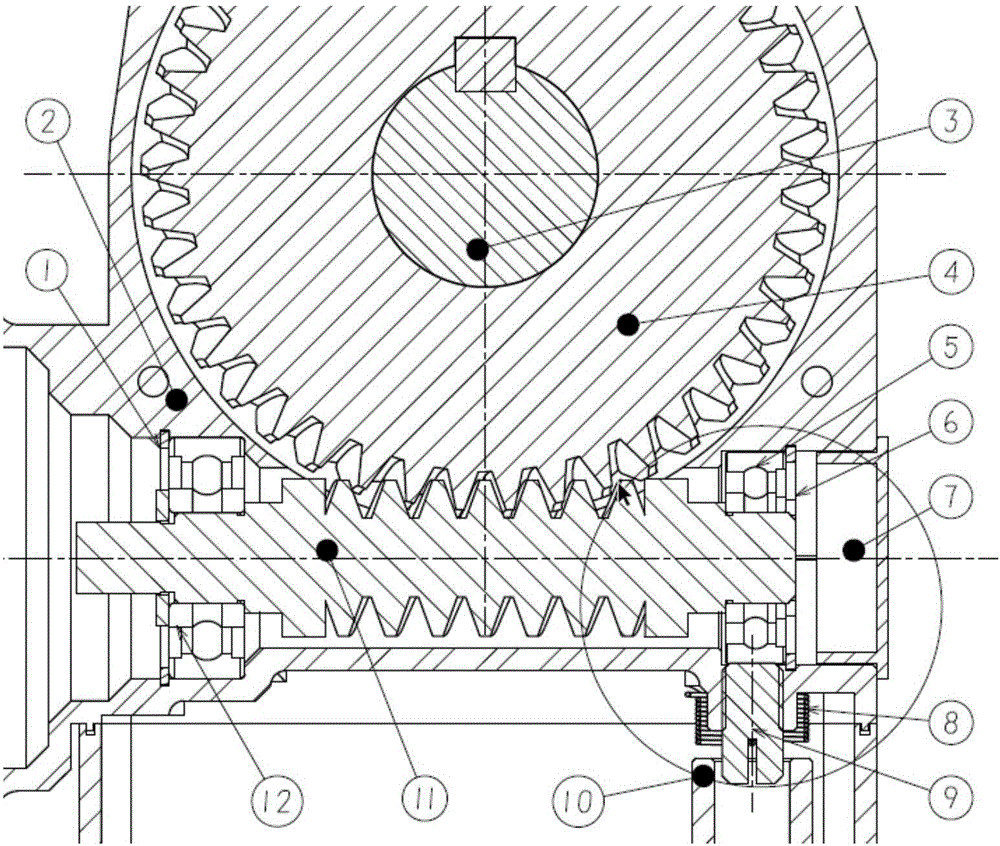

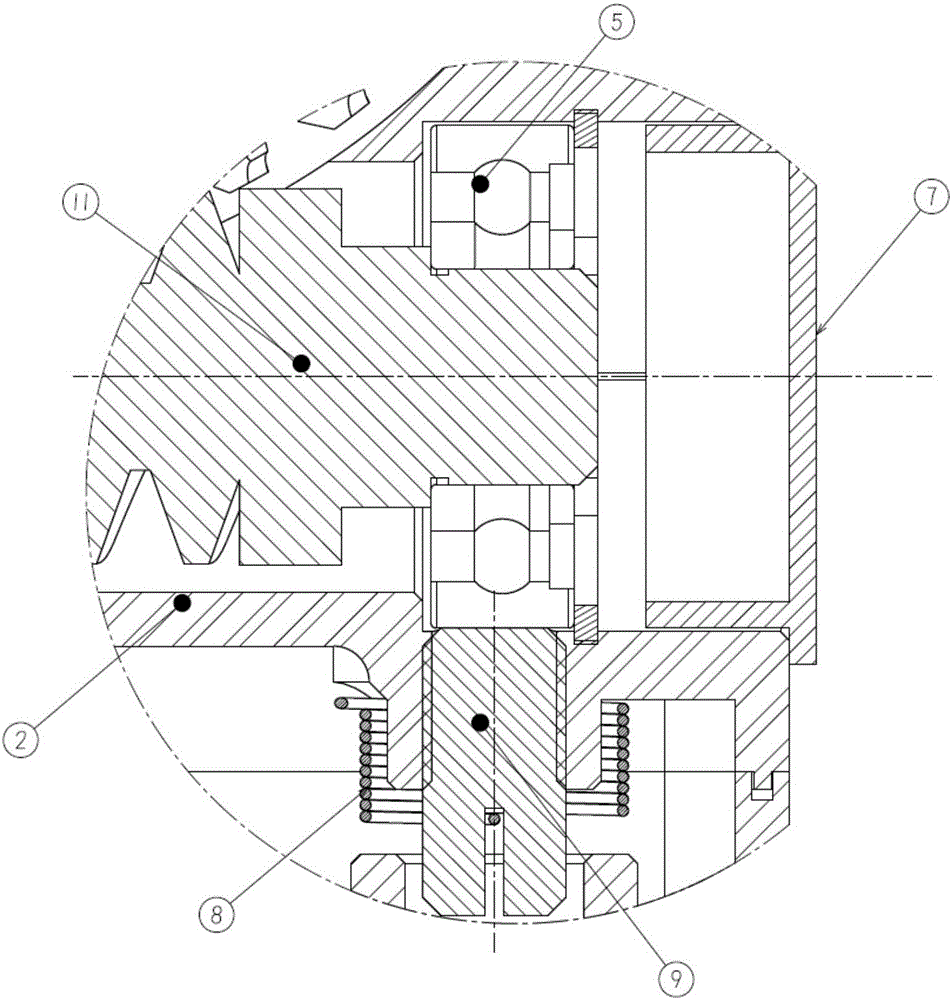

[0034] Such as Figure 1~4 As shown, a worm gear with a center distance adjustment and clearance elimination mechanism, the two ends of the worm 11 are respectively installed in the housing through the first bearing 5 and the second bearing 12, and the end cover 7 is installed on the right side of the first bearing 5, Dustproof and waterproof. Wherein, the first bearing 5 is installed in the waist-shaped installation hole of the housing 2, and its cross-sectional shape is as follows: image 3 As shown, the first bearing 5 can move smoothly in a small range in the waist-shaped installation hole along the direction connecting the two semicircles of the waist-shaped hole through the axial limit of the first retaining ring 6 and the shaft shoulder of the housing 2. The second bearing 12 is installed in the installation hole of the housing 2 with a small clearance or wrapped with elastic material, and is axially limited by the second retaining ring 1 and the shaft shoulder of the ...

Embodiment 2

[0039] A hydraulic brake with a worm gear and worm with a center distance adjustment and clearance elimination mechanism as described in Embodiment 1, comprising a brake motor, a worm gear and a brake master cylinder connected in sequence, the worm 11 in the worm gear It is coaxially connected with the output shaft of the brake motor, and the worm gear 4 is connected with the piston of the brake master cylinder through transmission.

Embodiment 3

[0041]The worm gear described in Embodiment 1 can also be applied to an electric power steering system, including a booster motor, a worm, and a worm gear. The worm in the worm gear is coaxially connected to the output shaft of the booster motor, and the worm gear is coaxially connected to the steering column or steering gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com