Urea injection control method based on real-time ammonia storage amount management for catalytic reduction of diesel

A technology of urea injection and control method, which is applied to the electric control of exhaust treatment devices, exhaust treatment, mechanical equipment, etc., which can solve the problems of low NOx conversion efficiency and ammonia leakage, so as to reduce secondary pollution and reduce NOx emissions , The effect of saving the amount of urea injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

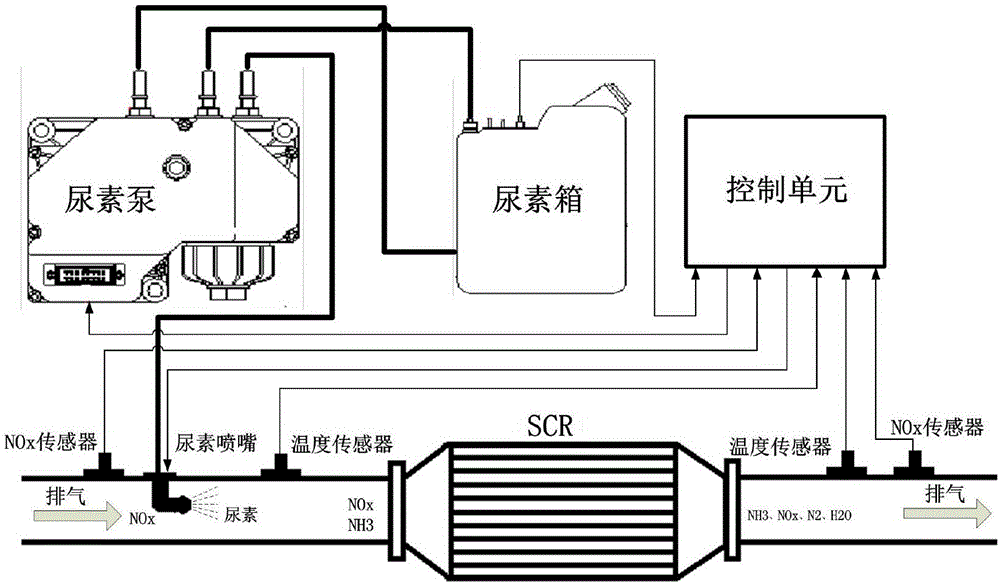

[0045] figure 1 It is a schematic diagram of an SCR system applicable to the present invention, and the SCR system includes an SCR reactor, a urea tank, a urea pump and a control unit. The SCR reactor is equipped with a catalyst carrier, which is NH 3 with NO x The urea tank is loaded with urea required by the SCR system; the urea pump delivers urea to the urea nozzle at a certain pressure; the control unit receives the signal from the SCR system sensor and controls the injection of urea. Equipped with NO upstream of the SCR x sensor, urea nozzle, temperature sensor and pressure sensor, with pressure sensor, temperature sensor and NO x sensor. SCR upstream and downstream NO x Sensors measure NO at SCR inlet and outlet x Mass concentration, the temperature sensor measures the temperature at the inlet and outlet of the SCR, the pressure sensor measures t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com