A multi-directional wide-frequency domain vibration isolation/shock reduction device

A wide-frequency domain, multi-directional technology, applied in the field of vibration isolation/shock reduction devices, can solve the problems of difficult full-frequency vibration isolation, high-frequency building excitation, and no energy consumption capability, and achieves improved horizontal vibration isolation and energy consumption. performance, improved horizontal vibration isolation and energy dissipation, and improved robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

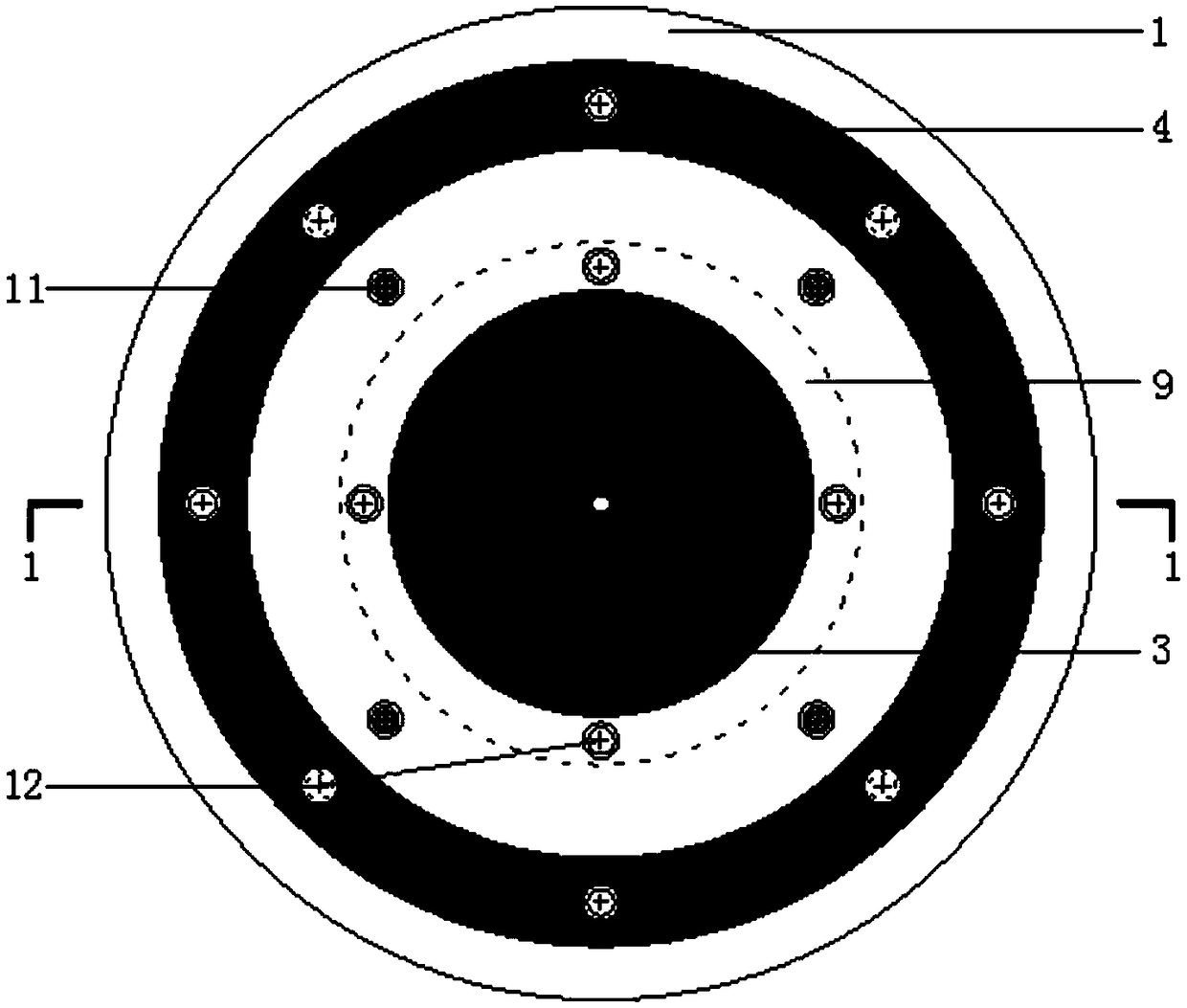

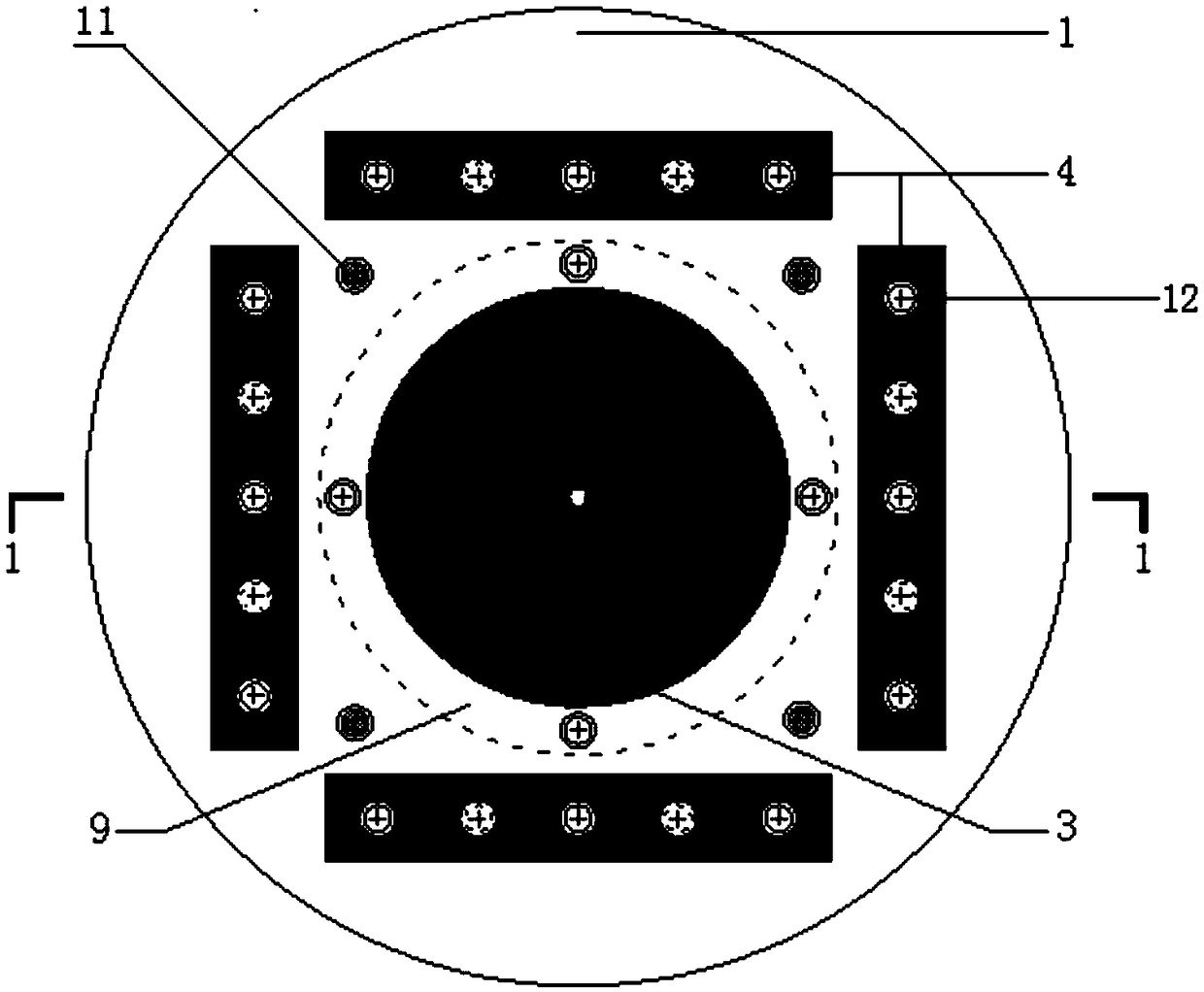

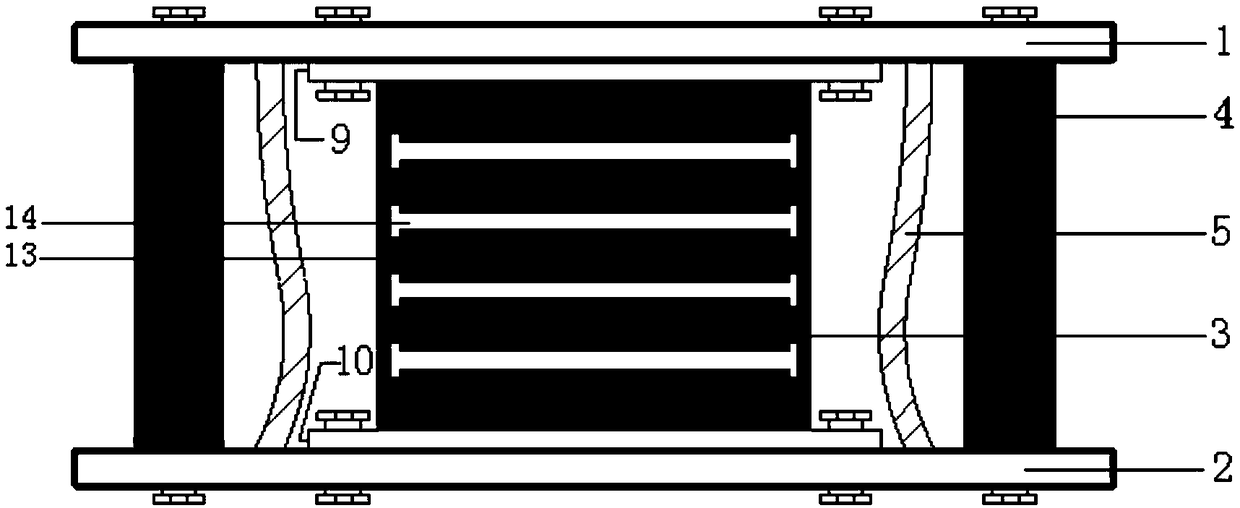

[0030] Such as Figure 1~5 As shown, the multi-directional wide-frequency vibration isolation / vibration reduction device of the present invention includes an upper steel plate 1 and a lower steel plate 2 arranged oppositely, and also includes a viscoelastic support 3 between the upper steel plate 1 and the lower steel plate 2, and the viscoelastic The support 3 includes a top plate 9 and a bottom plate 10 arranged horizontally, and a laminated support located between the top plate 9 and the bottom plate 10. The laminated support is formed by alternately laminating and vulcanizing viscoelastic material layers 13 and steel plates 14. The top plate 9 of the elastic sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com