A kind of anode variable speed movement electroplating device

A variable-speed motion and electroplating device technology, applied in electrolytic components, electrolytic process, etc., can solve problems affecting the average distribution of current, damage to electroplating parts, and large loss of sealing sleeves, etc., to reduce resistance loss, reduce power supply investment, and reduce total current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

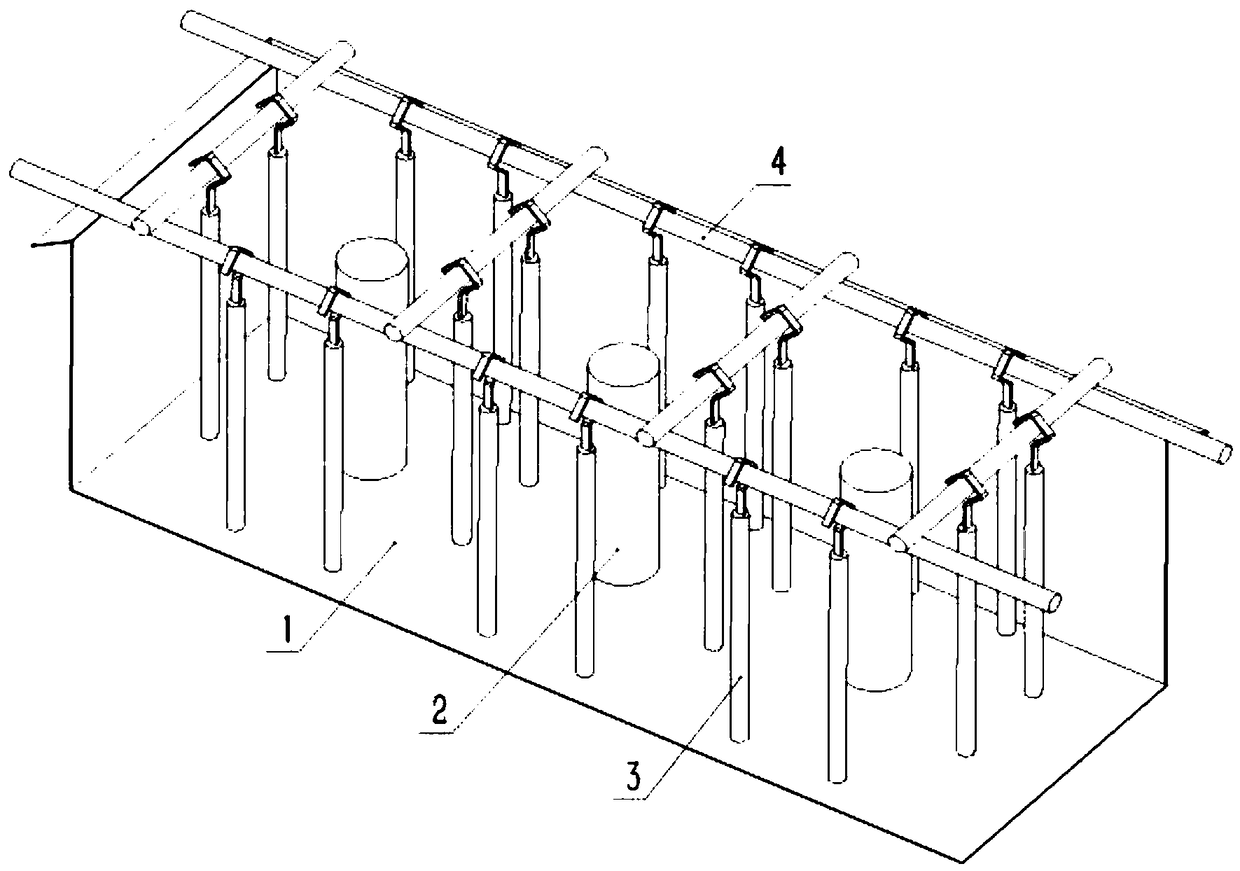

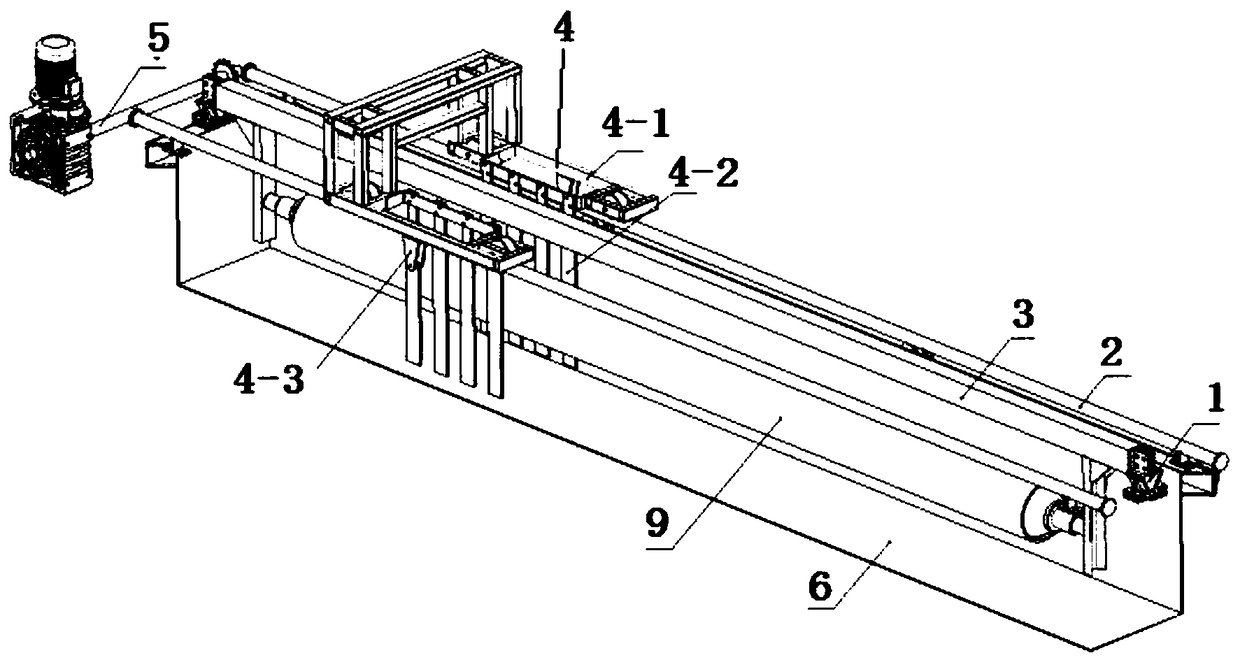

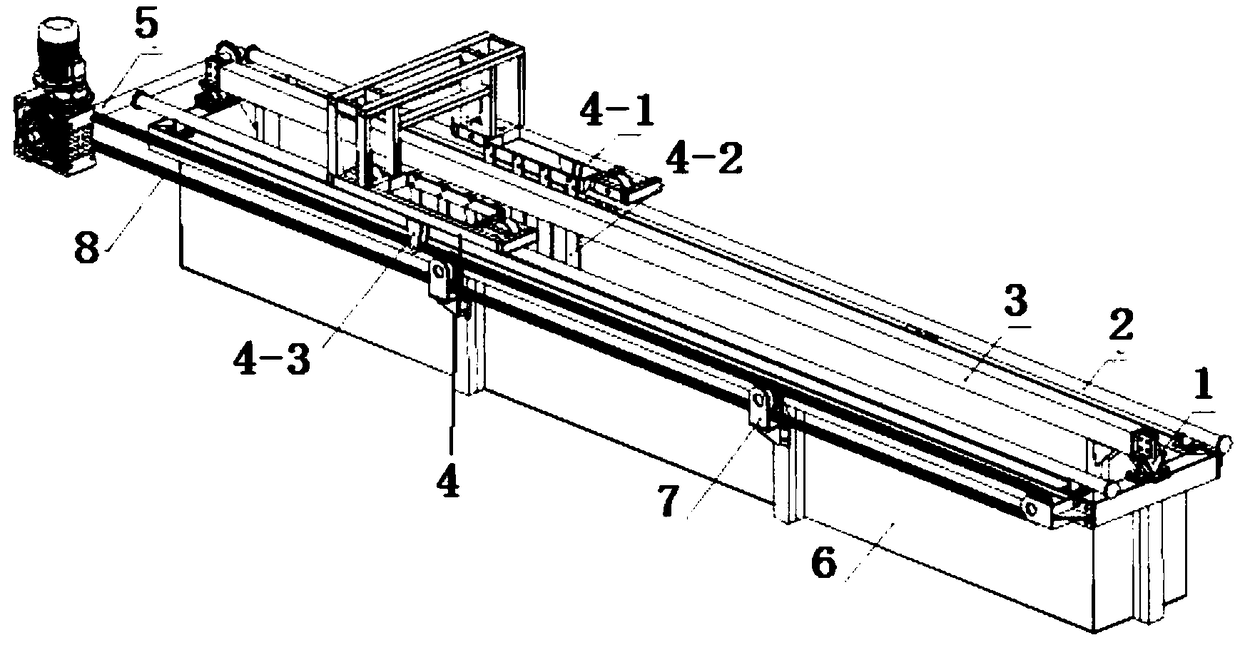

[0037] Refer to attached Figure 2-4 As shown, a kind of anode variable-speed motion electroplating device provided by the present invention includes a plating tank 6 for electroplating, a cathode tooling 3 is arranged in the plating tank 6, and a cathode workpiece to be electroplated is installed on the cathode tooling 3 9. The plating tank 6 is provided with an anode device 4 for electroplating with the cathode workpiece 9 ; the electroplating with the cathode workpiece 9 is realized through the anode device 4 .

[0038] Wherein, the cathode workpiece 9 is a product requiring electroplating, and in the electroplating process, the cathode is a product to be coated. Connect the product to be electroplated to the cathode, immerse in the solution, and apply a suitable current, and then the cathode will start to deposit a coating.

[0039] In order to realize electroplating with variable speed movement of the anode, the plating tank 6 is provided with a transmission device 5 for...

Embodiment 2

[0052] When using the present invention, refer to the attached Figure 2-4 , first install the plating tank 6 horizontally on the ground reference, then install the trolley guide rail 2 on both sides of the upper end surface of the plating tank 6, place the trolley 4-1 on the guide rail 2, and connect the connection on the trolley 4-1 Plate 4-3 is connected on the transmission chain 8, so that it can slide back and forth under the traction of transmission device 5. In addition, the cathode workpiece 9 is installed on the cathode tooling 3, and the cathode tooling 3 is mounted on the V-shaped copper seat 1 on the upper end surface of the plating tank 6 for fixing and conduction.

[0053] The electroplating process in the present embodiment is specifically as follows:

[0054] First, pre-plating treatment is required;

[0055] Then enter the tank for electroplating;

[0056] 1) Install the tooling on the pre-plating-treated workpiece according to the process requirements, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com