fe-ti-tb ternary compound coal-saving sulfur-fixing and decoking additive and its preparation method and application

A fe-ti-tb, 1. fe-ti-tb technology, applied in fuel additives, chemical instruments and methods, solid fuels, etc., can solve the problems of unsatisfactory results, low coal burnout rate, and low combustion efficiency, etc. problems, to achieve the effect of improving combustion efficiency, simple material selection, and increasing sensible heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

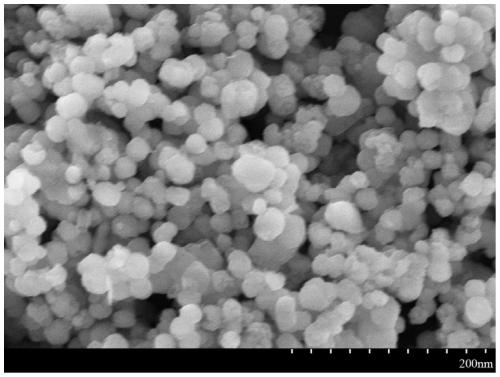

[0020] The preparation method of Fe-Ti-Tb ternary compound coal-saving sulfur-fixing and decoking additive comprises the following steps: first, the preparation concentration is 2mol / L FeCl 2 Ethanol solution 1L, then add 1mol tetra-n-butyl titanate (TNB), then slowly add 0.1mol / L TbCl 3 100ml of ethanol solution, after mixing evenly, drop 1L of NaOH ethanol solution with a concentration of 10mol / L at a rate of 30ml / min, after aging for 24h, drop in 0.67mol of hydrogen peroxide under the protection of nitrogen atmosphere, and keep warm at 60-70°C After 1 hour, a magnet was used to separate the precipitate, and after vacuum drying at 75°C and vacuum calcination at 500°C, the powder material obtained was the Fe-Ti-Tb ternary composite coal-saving sulfur-fixing and decoking additive.

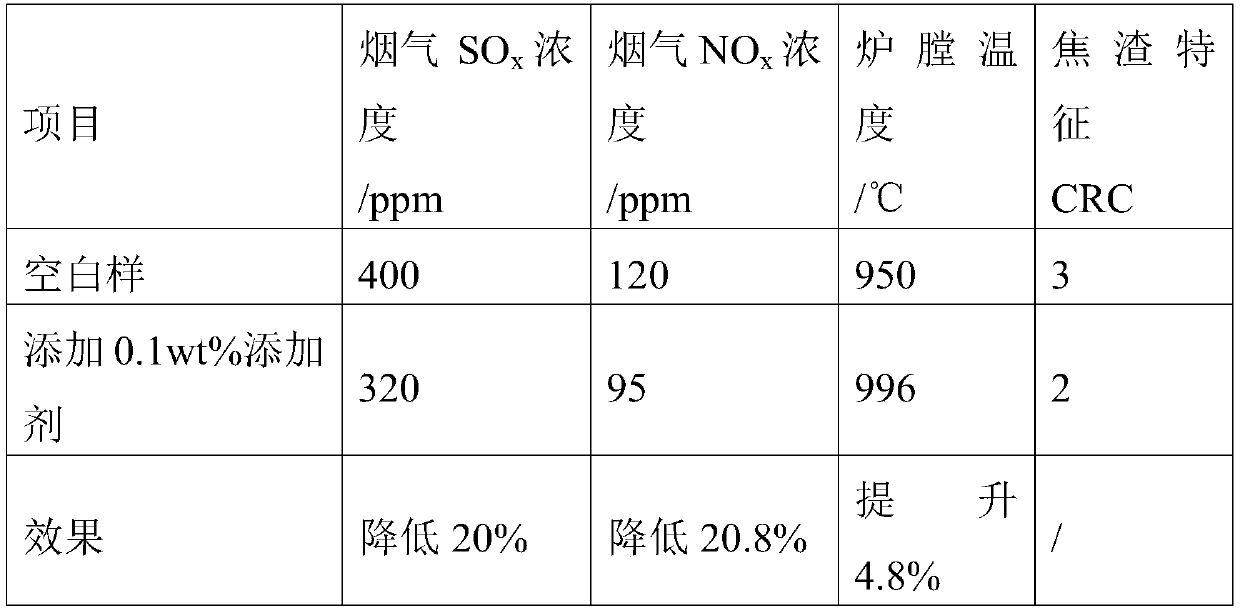

[0021] The prepared Fe-Ti-Tb ternary composite coal-saving sulfur-fixing and decoking additive was added to the coal-water slurry experimental furnace for testing, and its energy-saving and emissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com