Synergistic domestic garbage and high-alkali coal pyrolysis gasification device and method adopting three-stage type process

A technology for domestic waste, pyrolysis and gasification, which is applied in the field of domestic waste and high-alkali coal synergistic pyrolysis and gasification devices, can solve the problems of increasing investment and operation costs, acid rain, shortening the service life of gasifiers, etc. Dioxin content and effect of reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

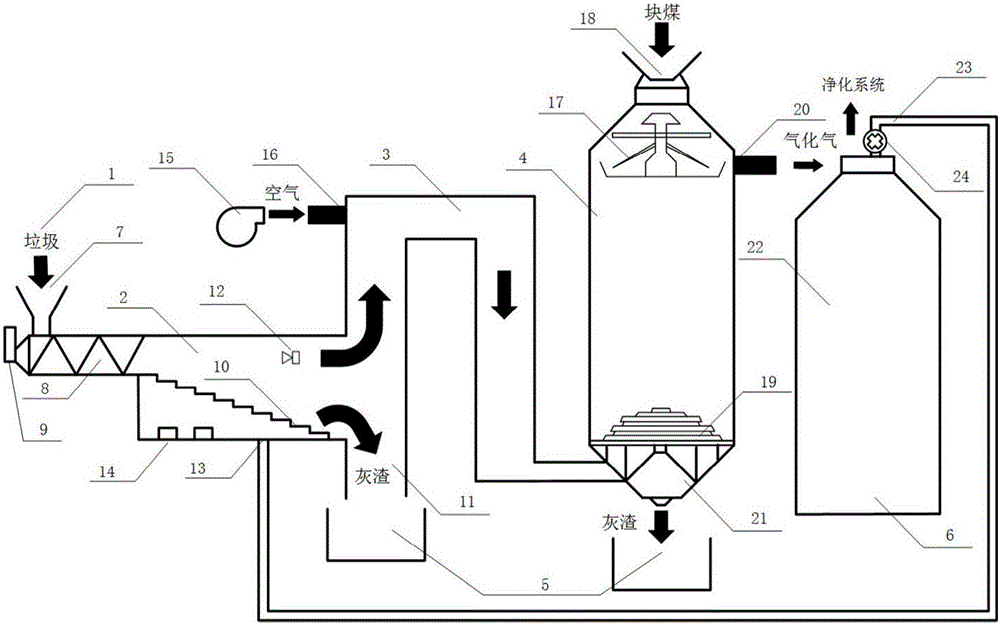

[0052] The present invention will be further described below in conjunction with drawings and embodiments.

[0053] like figure 1 Shown, the concrete implementation of the present invention is to comprise pyrolysis chamber 2, combustion chamber 3 and gasification chamber 4 and feeding system 1, ash collecting device 5 and gas storage device 6, pyrolysis chamber 2, combustion chamber 3 and gasification chamber 4 are connected in sequence to form a three-stage synergistic pyrolysis treatment environment for domestic waste and high-alkali coal, with pyrolysis chamber 2 as the first stage, combustion chamber 3 as the second stage, and gasification chamber 4 as the third stage; feeding system 1 Connected to the entrance of pyrolysis chamber 2, the ash recovery ports of pyrolysis chamber 2 and gasification chamber 4 are provided with ash collection device 5, and gasification chamber 4 is connected to pyrolysis chamber 2 through gas storage device 6.

[0054] The feeding system 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com