Triangle adhesive and preparation method thereof

A technology of apex rubber and rubber material, which is applied in the field of tire processing, can solve the problems of vehicle control failure, apex flexion and bending, apex breakage, etc., and achieve the effect of improving flexibility, promoting cross-linking density, and promoting improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

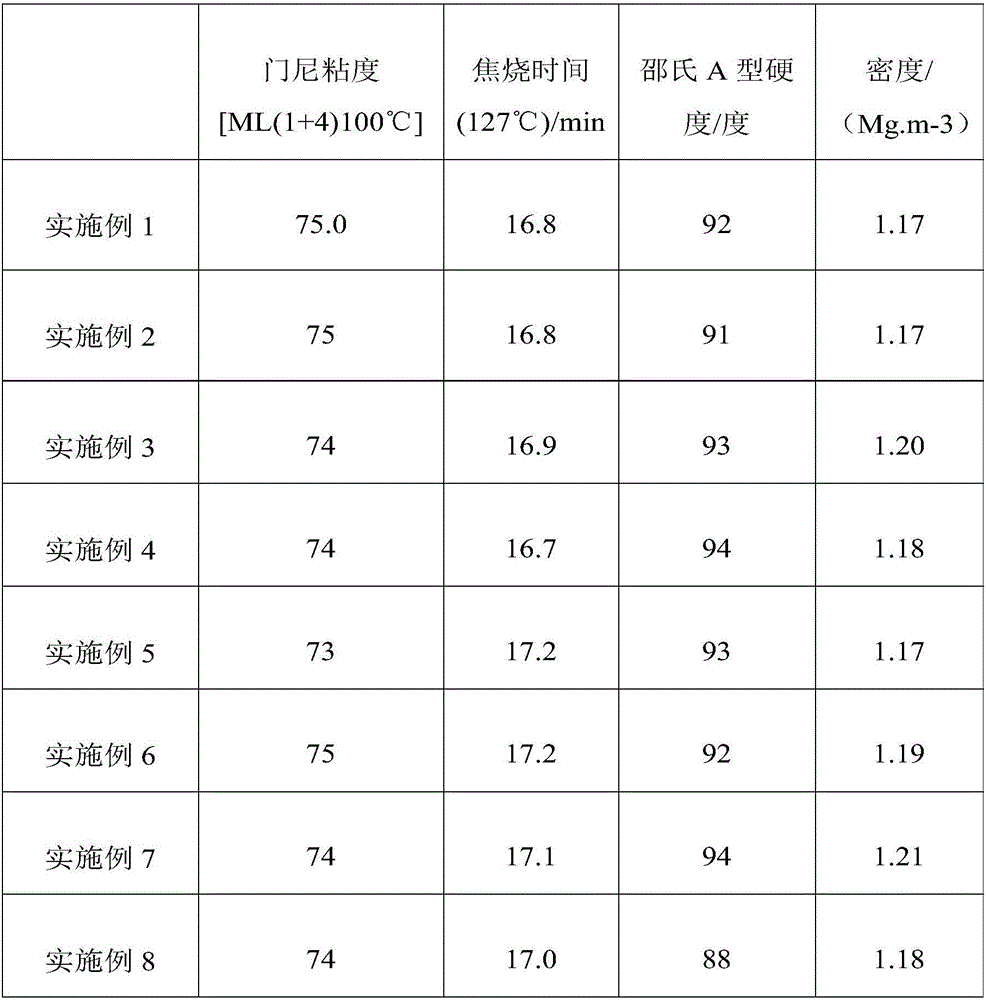

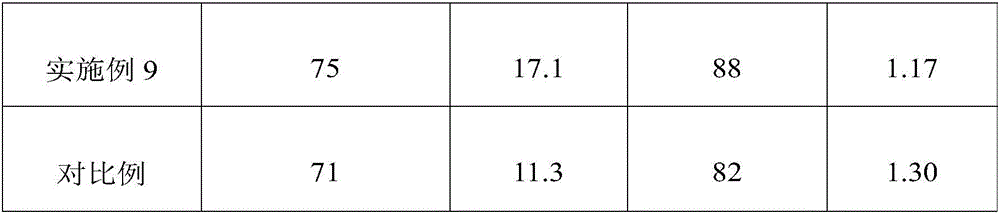

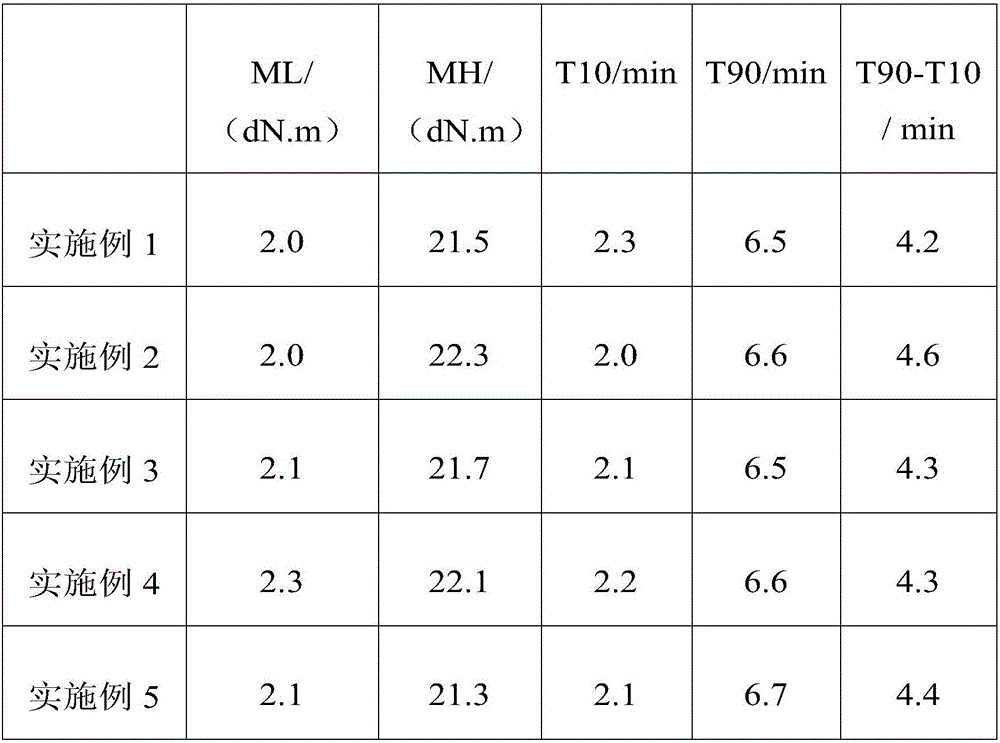

Examples

preparation example Construction

[0034] A preparation method of apex rubber, which comprises three stages of mixing steps:

[0035] The first stage of mixing: 50-70 parts by weight of natural rubber and 30-50 parts by weight of butadiene rubber are mixed for the first time at a temperature of 90-110° C. for 20-40 seconds. Natural rubber and butadiene rubber are mixed as main ingredients at a temperature of 90-110°C for 20-40s to reduce the viscosity of natural rubber and butadiene rubber and maintain fluidity so that they can be fully mixed with other raw materials.

[0036] After the first mixing, add 2-3 parts by weight of stearic acid, 4-8 parts by weight of zinc oxide and 48-60 parts by weight of carbon black, and then add 5-8 parts by weight of aromatic oil at a temperature of 145-165 °C Next, carry out the second mixing for 1-2min to generate the initial compound.

[0037] Adding stearic acid and zinc oxide as activators together with carbon black into the rubber compound obtained after the first mixin...

Embodiment 1

[0046] A kind of apex rubber, by weight, its raw materials include: 55 parts of natural rubber, 45 parts of butadiene rubber, 2.3 parts of stearic acid, 78 parts of carbon black, 6 parts of zinc oxide, 6.5 parts of aromatic oil, accelerator TBBS 1.25 parts, 0.85 parts of accelerator HMT, 6 parts of insoluble sulfur, 0.1 parts of anti-scorch agent CTP, 8.5 parts of phenolic reinforcing resin, 1.3 parts of anti-aging agent TMQ and 1.2 parts of anti-aging agent 4020.

[0047] The preparation method of above-mentioned apex, it may further comprise the steps:

[0048] Mix the above-mentioned natural rubber and butadiene rubber at 90°C for 40s, then add stearic acid, zinc oxide, anti-aging agent 4020, anti-aging agent TMQ and 75% carbon black, then add aromatic oil at 145 Mix for 2 minutes under the condition of ℃ to generate the initial rubber compound.

[0049] The initial compound was kneaded at a temperature of 90°C for 40s, then the phenolic reinforcing resin and the remaining...

Embodiment 2

[0052] A kind of triangle rubber, by weight, its raw material comprises: 68 parts of natural rubber, 32 parts of butadiene rubber, 2.3 parts of stearic acid, 65 parts of carbon black, 6 parts of zinc oxide, 5.5 parts of aromatic hydrocarbon oil, accelerator TBBS 1.36 parts, 1.2 parts of accelerator HMT, 5.4 parts of insoluble sulfur, 0.1 parts of anti-scorch agent CTP, 12 parts of phenolic reinforcing resin, 1.3 parts of anti-aging agent TMQ and 1.2 parts of anti-aging agent 4020.

[0053] The preparation method of above-mentioned apex, it may further comprise the steps:

[0054] Mix the above-mentioned natural rubber and butadiene rubber at 92°C for 38s, then add stearic acid, zinc oxide, anti-aging agent 4020, anti-aging agent TMQ and 75% carbon black, then add aromatic oil at 148 Under the temperature condition of ℃, knead for 2 minutes to form the initial rubber compound.

[0055] After the initial compound was kneaded at 92°C for 38s, phenolic reinforcing resin and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com