Kitchen garbage composting conditioner and kitchen garbage treatment method

A technology of kitchen waste and treatment method, which is applied in the field of waste resource utilization, can solve the problems that aerobic microorganisms cannot obtain sufficient nutrients, affect the composting process and compost quality, and cannot realize the utilization of waste clay resources, so as to improve the composting effect and increase Stability, effect of reducing nitrogen loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

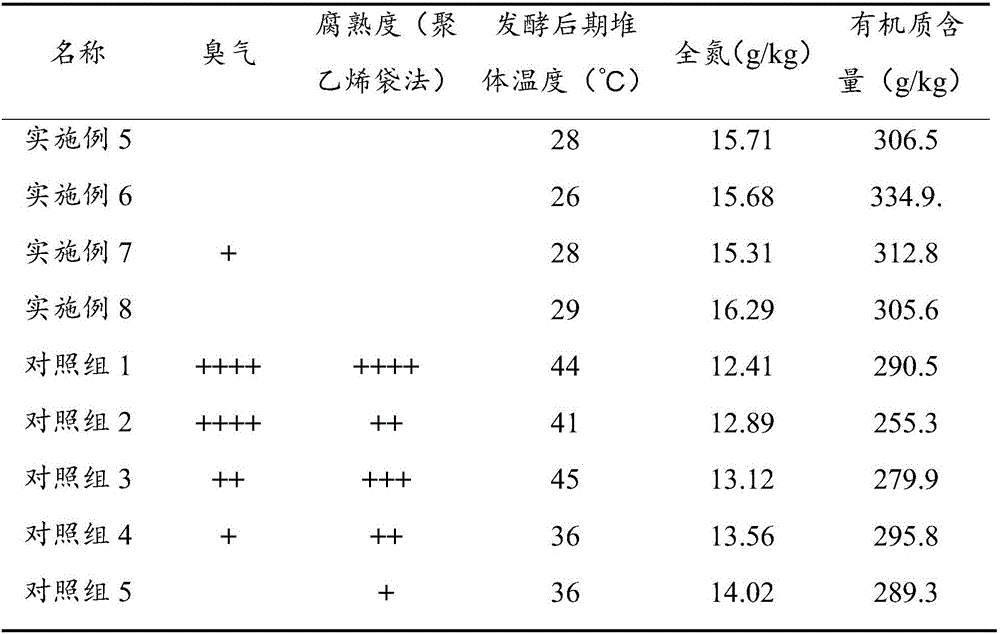

Examples

Embodiment 1

[0024] This example provides a food waste composting conditioner, the raw material formula of which is: 85 parts of decomposed substrate, 2 parts of magnesium sulfate, 3 parts of superphosphate, 5 parts of desulfurized gypsum powder, and 5 parts of plant ash.

[0025] The preparation method of kitchen waste composting conditioner is as follows:

[0026] (1) Preparation of decomposed matrix: mix waste clay, agricultural and forestry waste, compound microbial agent, surfactant (AEO-9)) in a ratio of 75:75:0.1:0.02, adjust the water content to about 45%, and adjust the C / N is about 23; compost fermentation at room temperature, turn the pile continuously, maintain the internal temperature of the pile at 25-40°C, and maintain the temperature for 48 hours; quickly dry at room temperature until the moisture content is not more than 20%, that is, a decomposed matrix, in which the complex microorganisms The bacterial agent is composed of Bacillus coagulans and Bacillus subtilis mixed ...

Embodiment 2

[0029] This example provides a food waste composting conditioner, which is basically the same as Example 1, except that the ratio of waste clay, agricultural and forestry waste, compound microbial agent and surfactant is 90:60:0.1:0.02 .

Embodiment 3

[0031] This example provides a food waste composting conditioner, which is basically the same as Example 1, except that the ratio of waste clay, agricultural and forestry waste, compound microbial agent and surfactant is 65:85:0.1:0.02 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com