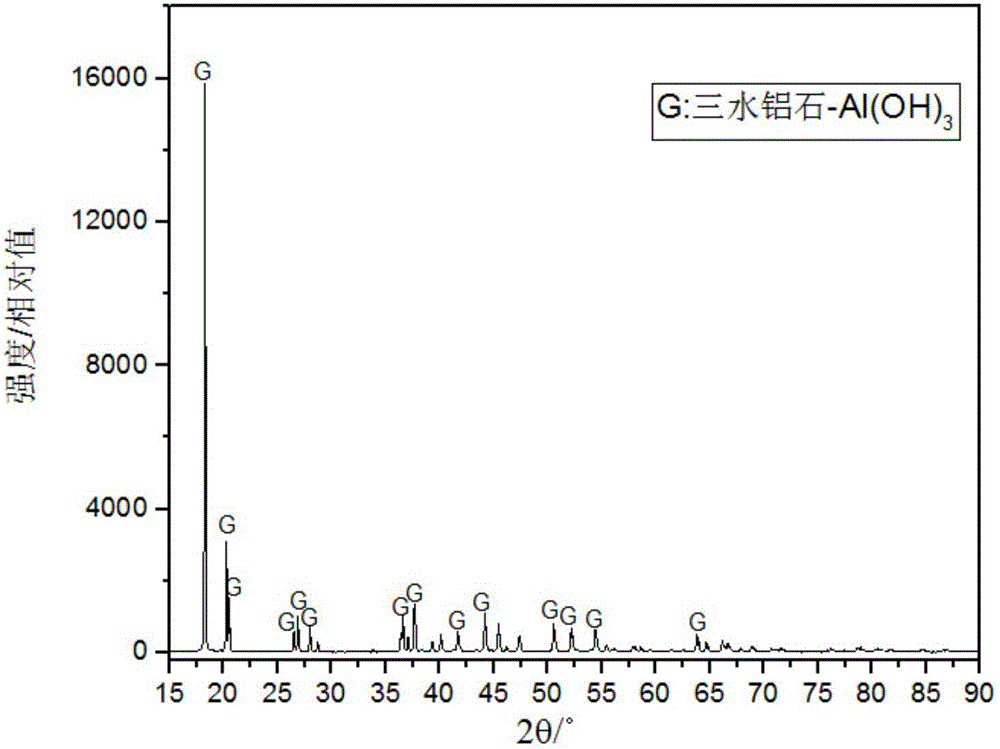

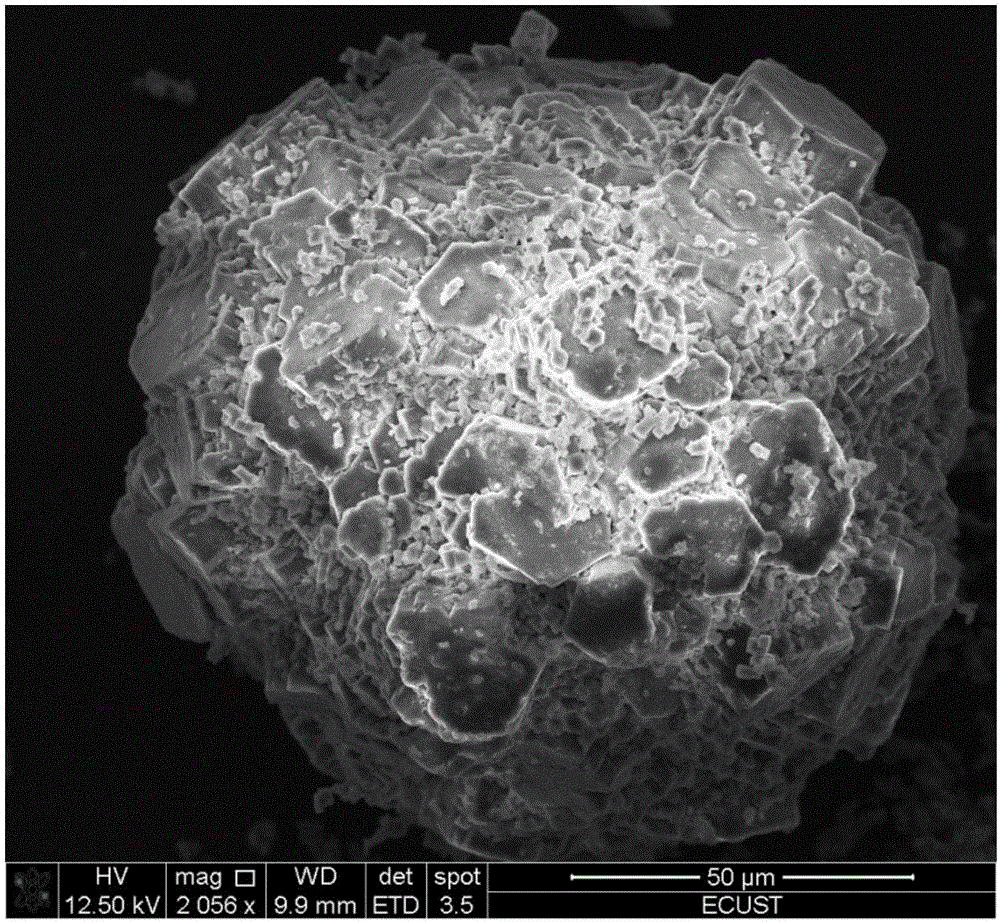

Technique for decomposing potassium aluminate solution seed crystal to produce aluminum hydroxide

A technology of aluminum hydroxide and process method, applied in the direction of alkali metal aluminate/alumina/aluminum hydroxide preparation, chemical instruments and methods, aluminum compounds, etc., to achieve large particle size, high product purity and good shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step (1): Alkali concentration (in K 2 Potassium aluminate solution of 240g / L in terms of O and a caustic ratio of about 1.4 is poured into the reactor, and the water bath circulation and stirring are turned on to make the temperature and concentration of the solution uniform, and the initial decomposition temperature is controlled to be 70°C. For aluminum hydroxide crystal seeds, the seed crystal ratio, that is, the seed crystal coefficient, is selected as 2, and the stirring rate is selected as 200 rpm.

[0030] Step (2): During the seed crystal decomposition reaction process, the cooling rate is controlled at 0.5-2°C / h to ensure the best decomposition yield and rate. At the same time, 20ml of samples are taken every 5 hours. After centrifugation, take the upper layer The clear liquid was sampled to analyze the content of potassium oxide and aluminum oxide, and the lower layer of solid precipitate was washed with hot deionized water for 2-5 times and then dried at a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com