High-efficiency iron removal device for lithium battery material

A lithium battery material and high-efficiency technology, applied in magnetic separation, solid separation, grain processing, etc., can solve problems such as waste of resources, time-consuming and labor-intensive, and harm to health, and achieve simple design structure, good development prospects, and good working performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

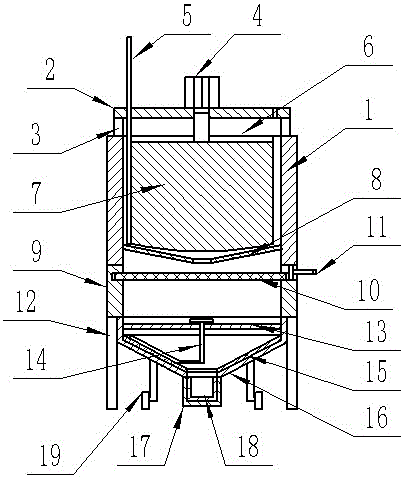

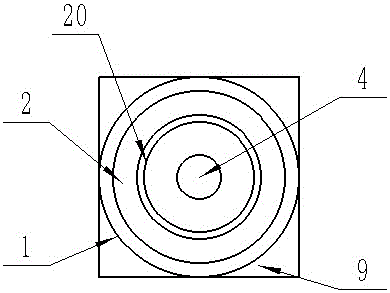

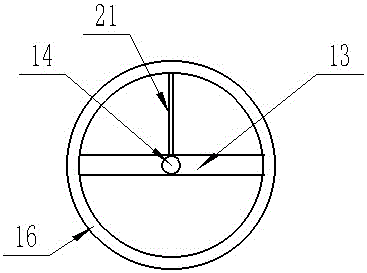

[0017] see Figure 1-3 , a high-efficiency lithium battery material iron removal device, including a crushing cylinder 1 and a conical receiving cylinder 16; the crushing cylinder 1 is provided with a feed port 6, a connecting column 3, a cover plate 2, a wheel column 7, a motor 4, Funnel bottom plate 8, ring mouth 20, material removal bar 5, transition box 9, screen 10, draw frame 11 and support foot 12; The described feeding port 6 is arranged on the upper end surface of the crushing cylinder 1, and the feeding port 6 is convenient for workers Put in the battery material; there are two connecting columns 3, which are respectively vertically arranged on the left and right sides of the edge of the feed port 6; the cover plate 2 is horizontally fixed at the upper ends of the two connecting columns 3, In order to prevent the material from splashing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com