Process system for preparing ethambutol hydrochloride

A technology of ethambutol hydrochloride and process system, which is applied in the field of process equipment for preparing ethambutol hydrochloride, which can solve the problems of easy explosion, uncontrolled reaction, and poor control of process indicators, etc., and prevent flammable and explosive accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

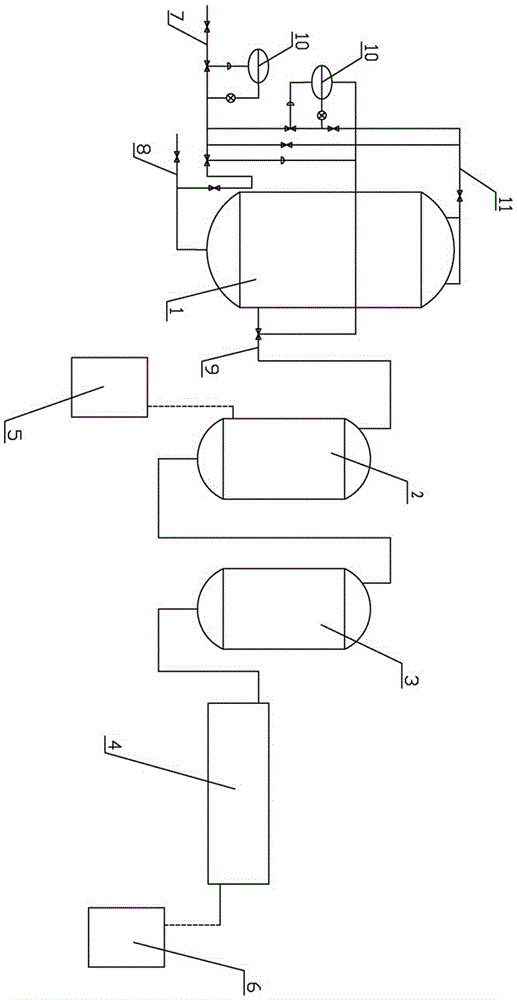

[0012] Such as figure 1 , a process system for preparing ethambutol hydrochloride, arranged from upstream to downstream, including reaction kettle 1, distillation kettle 2, dissolution kettle 3, filter press equipment 4; also includes recovery tank 5, which is located in the distillation tank 5 Downstream of still 2; Also comprise collecting tank 6, and this collecting tank 6 is positioned at the downstream of described filter press equipment 4; Also comprise nitrogen protection device, this nitrogen protection device comprises inlet nitrogen pipe 7, pressure alarm device 10, this inlet nitrogen pipe 7 is connected to the top pipe of the reaction kettle 1, and is connected to the sewage pipe 8 and the discharge pipe 9 of the reaction kettle 1, and the pressure alarm device 10 is respectively located in the nitrogen inlet pipe 7 and the sewage pipe 8 , The connecting pipe between the discharge pipe 9.

[0013] In this embodiment, there are two connecting pipes between the nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com