Preparation method of polymer-based metal organic framework hybrid membrane

An organic framework and polymer technology, applied in the field of preparation of polymer-based metal-organic framework hybrid membranes, can solve the problems of low flux and low rejection rate, achieve high porosity and specific surface area, and the preparation method is simple and easy , easy-to-magnify effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The first step is to immerse the polyacrylonitrile-based membrane in a 2mol / L sodium hydroxide solution and hydrolyze it at 65°C for 1 hour. The hydrolysis reaction occurs in the polyacrylonitrile, and the nitrile group is converted into a carboxyl group, making the membrane surface negatively charged;

[0043] In the second step, the hydrolyzed polyacrylonitrile (HPAN) obtained in step one is repeatedly rinsed with deionized water, and then the obtained HPAN membrane is immersed in deionized water for 24 hours;

[0044] In the third step, configure 0.2mol / L zinc nitrate (Zn(NO 3 ) 2 ) aqueous solution, and 0.4wt.% polyethyleneimine (PEI) aqueous solution, and the two are mixed in equal volumes to form a water phase solution; configure 0.2mol / L 2-methylimidazole / n-hexane solution as an oil phase solution ;

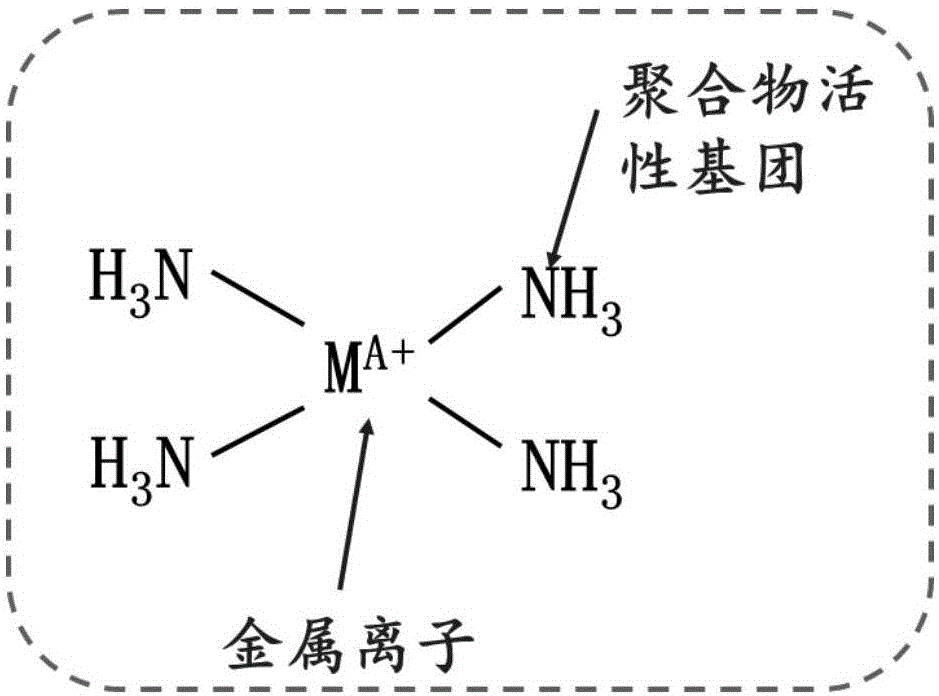

[0045] In the fourth step, the HPAN film obtained in step two is immersed in the Zn(NO 3 ) 2 and PEI mixed aqueous solution for 1h, Zn 2+ Chelate with cationic...

Embodiment 2

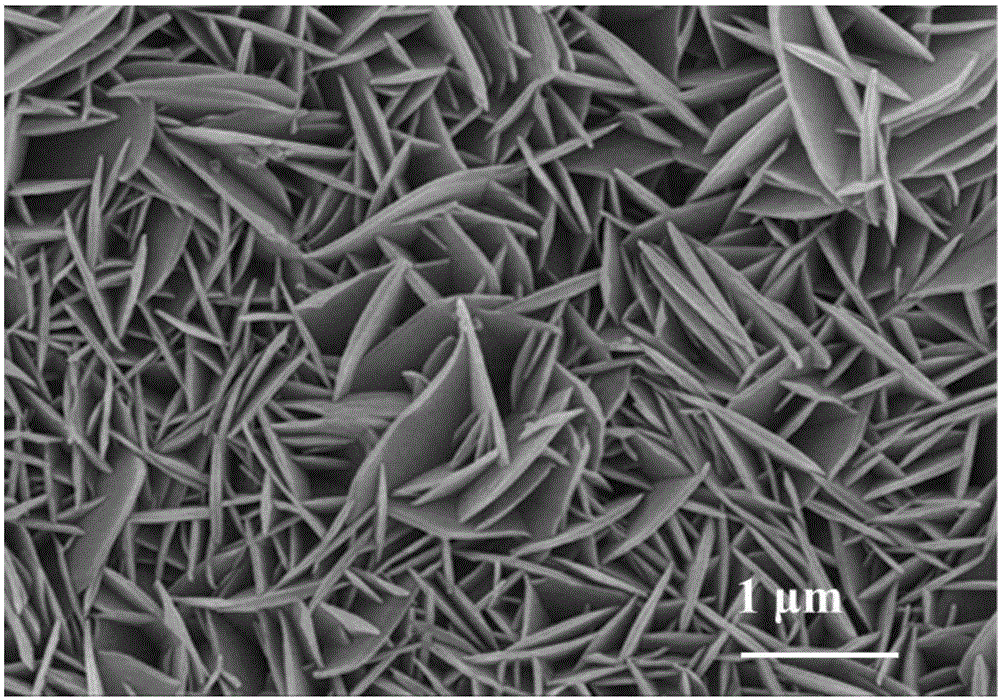

[0052] The interface reaction time of step 6 in embodiment 1 is adjusted to 60min, all the other conditions are the same as embodiment 1. The prepared MOFs hybrid membrane nanofiltration membrane is used for cross-flow filtration of 100mg / L Congo red aqueous solution, and the permeation flux is 450.8L m -2 h -1 ·MPa -1 , The rejection rate is 99.5%.

Embodiment 3

[0054] Zn(NO 3 ) 2 The water solubility concentration is adjusted to 0.25mol / L, and the concentration of the 2-methylimidazole / n-hexane solution is adjusted to 0.25mol / L; other conditions are the same as in Example 1. The prepared MOFs hybrid membrane nanofiltration membrane is used for cross-flow filtration of 100mg / L Congo red aqueous solution, and the permeation flux is 750.8L m -2 h -1 ·MPa -1 , The rejection rate is 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com