Preparation method of drinkable green tea powder jelly

A technology of matcha powder and jelly, which is applied in the field of preparation of matcha powder inhalable jelly, can solve problems such as hidden dangers of human health and safety, achieve good market development potential and economic benefits, improve immunity, and remove free radicals in the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The composition ratio of matcha powder inhalable jelly is as follows (based on 100g):

[0027] Potassium chloride 300mg;

[0028] Compound rubber powder 450mg;

[0029] Fructose syrup 10g;

[0030] Sodium citrate 25mg;

[0031] Citric acid 35mg;

[0032] Tea powder 150mg;

[0033] ZnCl 2 20 mg;

[0034] Na 2 SO 3 45 mg;

[0035] water balance.

Embodiment 2

[0037] The composition ratio of matcha powder inhalable jelly is as follows (based on 100g):

[0038] Potassium chloride 550mg;

[0039] Compound rubber powder 300mg;

[0040] fructose syrup 12g;

[0041] Sodium citrate 18mg;

[0042] Citric acid 20mg;

[0043] Tea powder content is 180mg;

[0044] ZnCl 2 35 mg;

[0045] Na 2 SO 3 30 mg;

[0046] water balance.

Embodiment 3

[0057] The preparation method of matcha powder inhalable jelly is carried out as follows:

[0058] (1) At room temperature (25°C), weigh KCl, xanthan gum, gellan gum, and locust bean gum in proportion, add them to the container, and dry mix them evenly;

[0059] (2) Add distilled water to the uniform rubber powder obtained in step (1), place it in a water bath at 70-75°C, stir continuously and rapidly during this period, keep the colloid in a liquid state, and keep it under this process condition for later use;

[0060] (3) Weigh a certain amount of fructose syrup, add water and stir to dissolve, pour into (2), then add sodium citrate and citric acid, stir well and adjust the pH to 4.0-5.0.

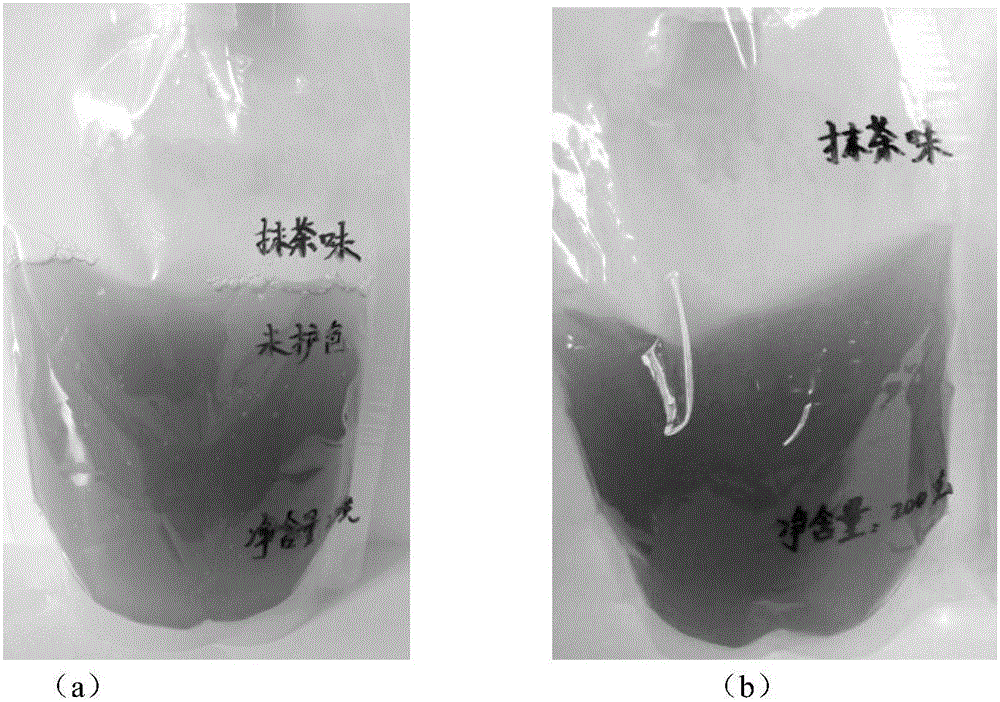

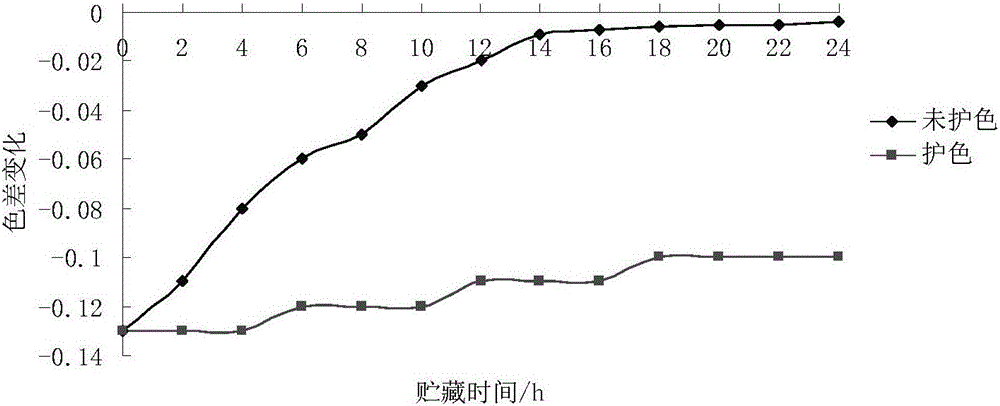

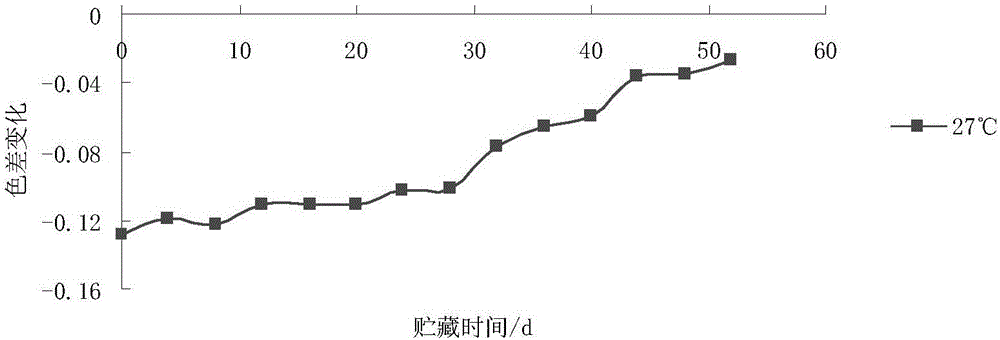

[0061] (4) Weigh an appropriate amount of matcha powder, add water to dissolve, then add an appropriate amount of color-protecting agent (not added in the comparative example), stir evenly, rinse it with a little distilled water into the main gel and continue stirring, so that the tea pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com