Controllable discharging and safe and automatic disassembling device for waste hard-housing power lithium-ion battery

A power battery, safe and automatic technology, used in battery recycling, solid waste removal, waste collector recycling, etc., can solve problems such as aggravating fire and aggravating battery adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation plan

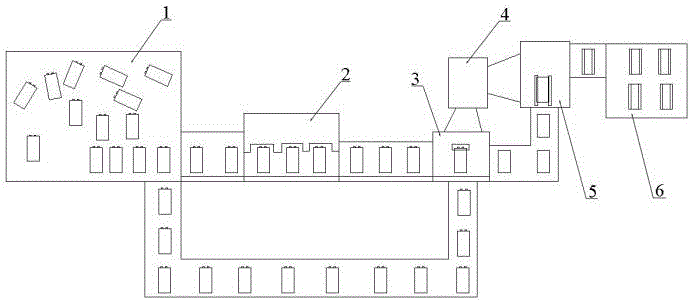

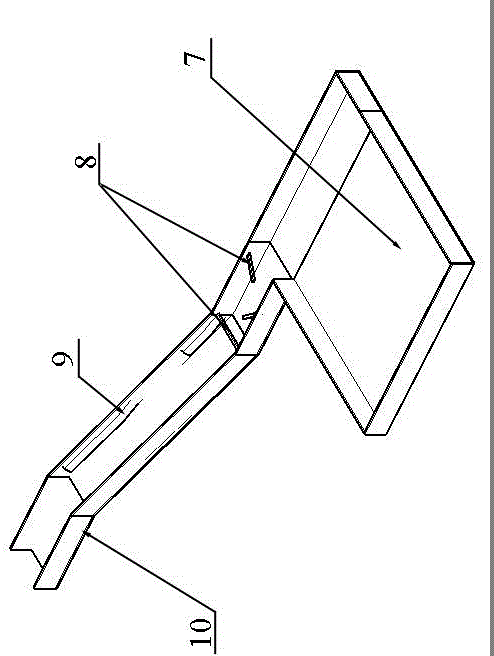

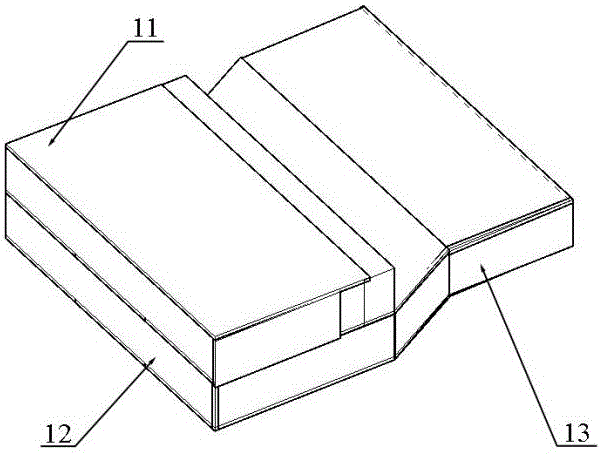

[0040] The lithium-ion power battery is first stored in the loading box and enters the conveyor belt through the belt. The batteries entering the conveyor belt are pushed to sorting one by one under the action of the height limit baffle. When the battery is conveyed through the two sides of the deflector plate, the unity in the length direction is firstly realized, and the distance between the batteries is adjusted. The batteries with uniform length direction are sent to the battery alignment station, and the relative position of the end caps of the batteries is checked and adjusted by the control imaging system. After the adjustment of the position of the end cap is completed, the voltage test and shunting of the battery are carried out. Those whose voltage reaches the safe voltage are sent to the cutting starting position, and those whose voltage is higher than the safe voltage are sent to the controllable discharge device for discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com