Device and method for measuring contact angle of solid surface based on ultrahigh vacuum condition

A technology of ultra-high vacuum and measuring devices, which is applied in the direction of measuring devices, surface/boundary effects, instruments, etc., can solve the problems of sample contact angle influence and inaccurate measurement, and achieve the effect of easy maintenance, simple design and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

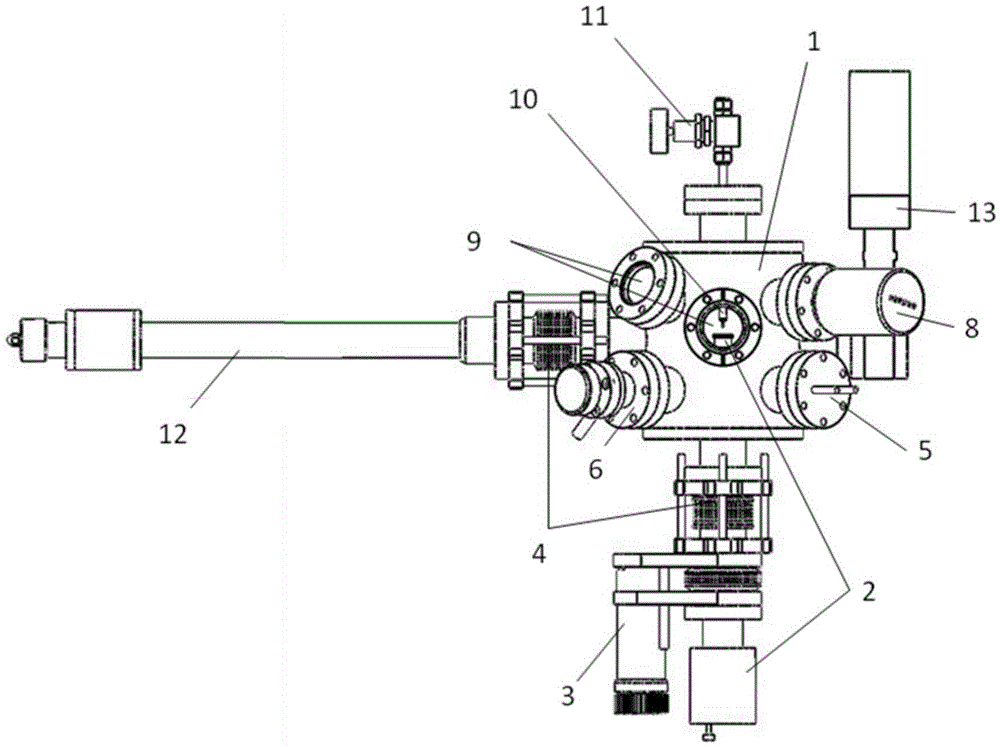

[0060] This device can directly measure the contact angle of the clean surface of the sample in ultra-high vacuum.

[0061] This measurement device based on the contact angle of the solid surface under ultra-high vacuum conditions is used to connect with the ultra-high vacuum system, and the clean samples prepared in the ultra-high vacuum system (such as graphene / Pt(111), BN / Pt(111), FeO / Au, etc.) can be directly transferred to the device through the sample transfer rod, close the gate valve of the device and ultra-high vacuum, and pass high-purity inert gas (99.999%) into the device through the inlet valve to an atmospheric pressure , open the liquid inlet valve, inject liquid through the liquid inlet gun, and form a microliter-level suspended droplet at the tip of the capillary, turn the linear drive to raise the sample stage, and wait until the droplet at the tip of the capillary touches the surface of the sample, Then adjust the linear drive to lower the sample stage, and ...

Embodiment 2

[0063] The device can independently measure the contact angle of samples under the protection of high-purity inert gas.

[0064] Although this device can be connected with the ultra-high system, it is also a system that can independently complete the test of the contact angle of the sample. The measurement method and process of the contact angle of the sample surface under the condition of high-purity inert atmosphere are as follows:

[0065] Open a horizontal glass window of the device, place the sample to be tested on the sample stage with tweezers, replace the new copper gasket and reinstall the glass window just opened, so that the device is in a sealed state.

[0066] Turn on the exhaust unit, and close the valve between the exhaust unit and the cavity when the vacuum unit has pumped the internal vacuum of the device to a level of 10-6mbar or lower.

[0067] Open the inlet valve, and feed high-purity inert gas into the device to an atmospheric pressure.

[0068] Open th...

Embodiment 3

[0072] The device can be used as an existing contact angle measuring device, and can independently measure the contact angle of a sample surface in an atmospheric environment.

[0073] The measurement method and process of the contact angle of the sample surface under atmospheric conditions are as follows:

[0074] Open a horizontal glass window of the device, and place the sample to be tested on the sample stage through tweezers.

[0075] Open the liquid inlet valve, inject liquid through the liquid inlet gun, and form a microliter-level suspended droplet at the needle tip of the capillary, turn the linear drive to raise the sample stage, wait until the small droplet at the capillary needle tip touches the sample surface, and then Adjusting the linear drive lowers the sample stage, allowing the droplet to transfer from the capillary tip to the sample surface.

[0076] Adjust the height of the sample surface so that the sample surface and the CCD maintain the same height, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com