Medical flash dryer

A flash dryer and flash evaporation technology, used in non-progressive dryers, dryers, drying solid materials, etc., can solve the problem that materials are easy to accumulate at the bottom of the main machine, materials fall to the bottom of the main machine, and hot air does not enter the air. Equalize the problem to achieve the effect of improving scrap and drying efficiency, improving drying efficiency, improving effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

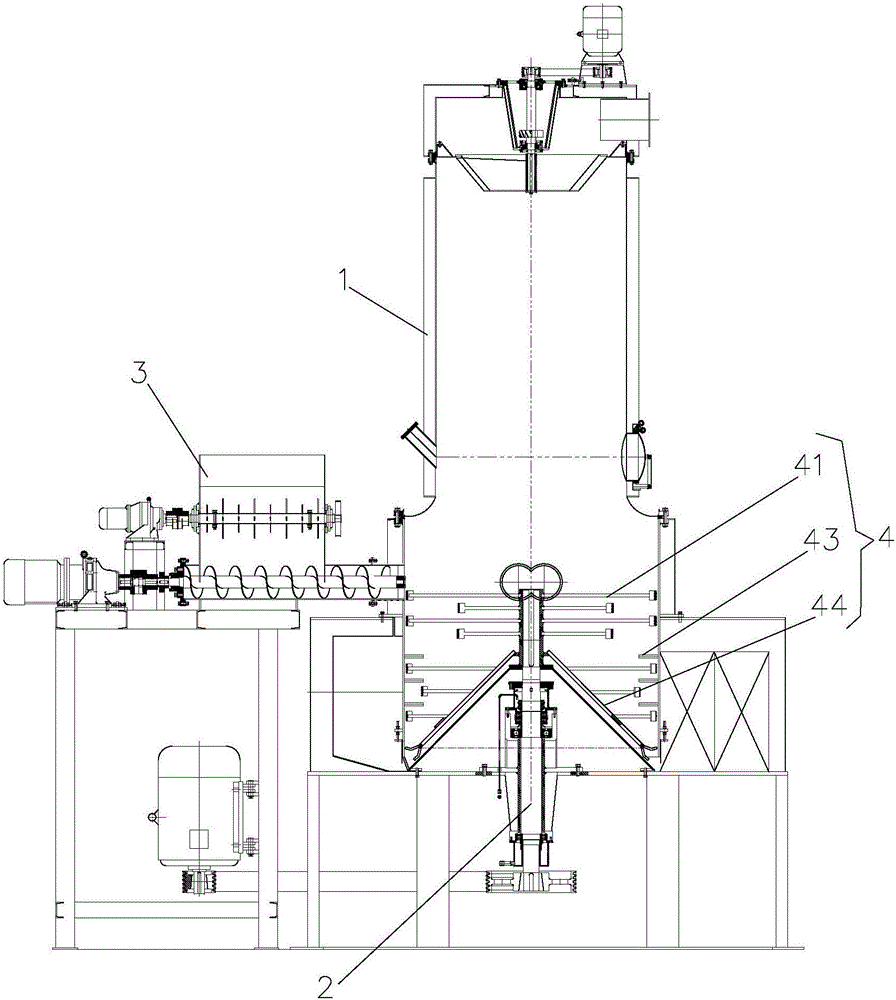

[0020] Such as Figure 1-3 , the pharmaceutical flash dryer in this embodiment includes: a flash host 1, a circular outlet is provided on the top of the flash host 1, a classifier is provided on the outlet, and the classifier includes: a movable gap Cooperate with the inverted cone cylinder on the above-mentioned discharge port, the inner wall of the inverted cone cylinder is evenly distributed with a plurality of scrap blades; each scrap blade is respectively distributed on the corresponding center vertical surface of the inverted cone cylinder; the The inverted cone cylinder is in transmission cooperation with a driving mechanism for driving the inverted cone cylinder to rotate around the central axis of the inverted cone cylinder. When working, the inverted conical cylinder rotates rapidly, so that the larger granular materials arriving there are crushed by multiple crushing blades, preventing them from falling to the bottom of the flash steamer and crushed again by the cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com