Spherical opposite-spraying type batched nanofiber yarn processing device and using method thereof

A nanofiber and processing device technology, which is applied in the direction of yarn, spinning machine, spinneret assembly, etc., can solve the problem of uncontrollable nanofiber yarn structure, low production speed of nanofiber yarn, and easy breakage of nanofiber yarn First-class problems, achieve the effect of improving spinning quality, convenient operation, and avoiding concentration fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

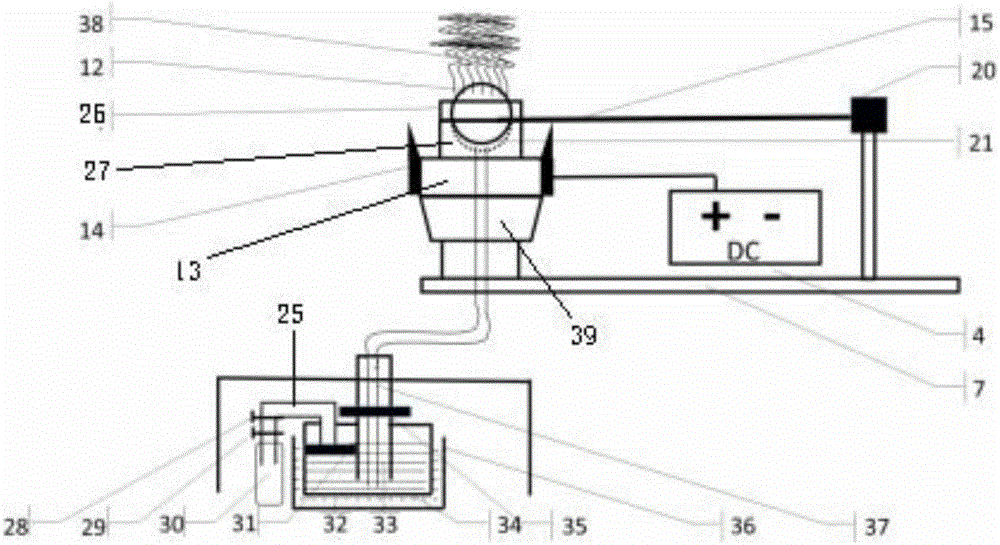

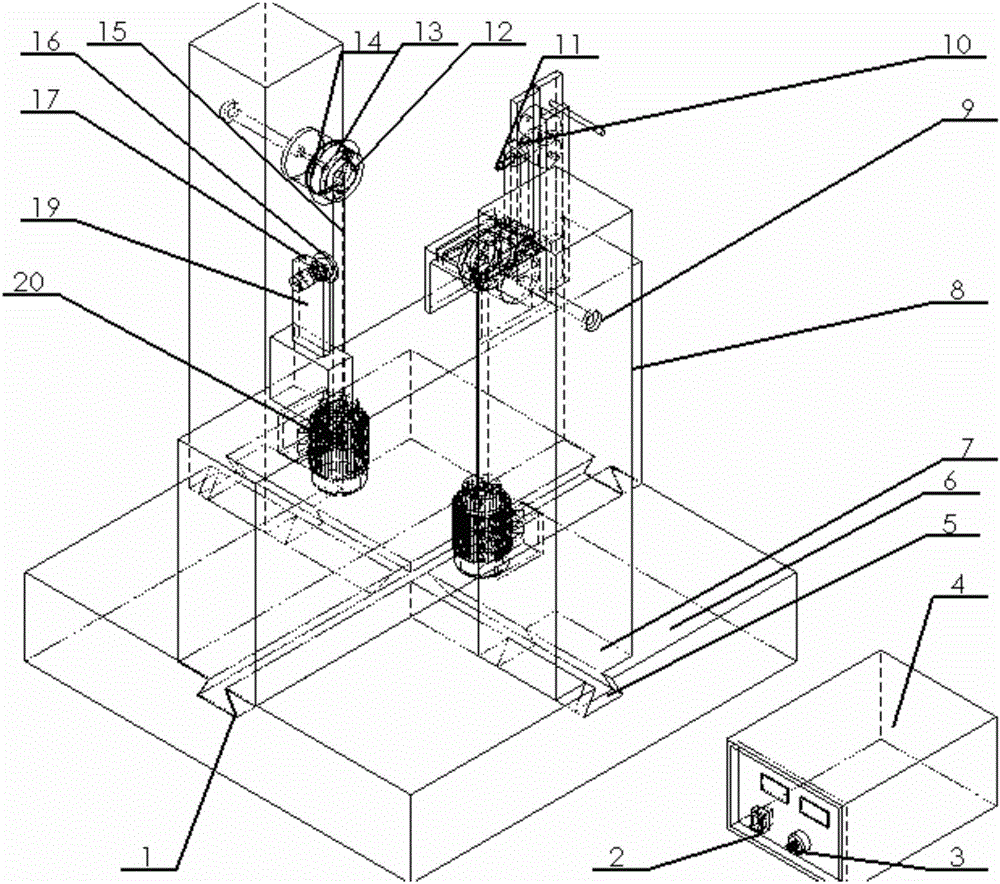

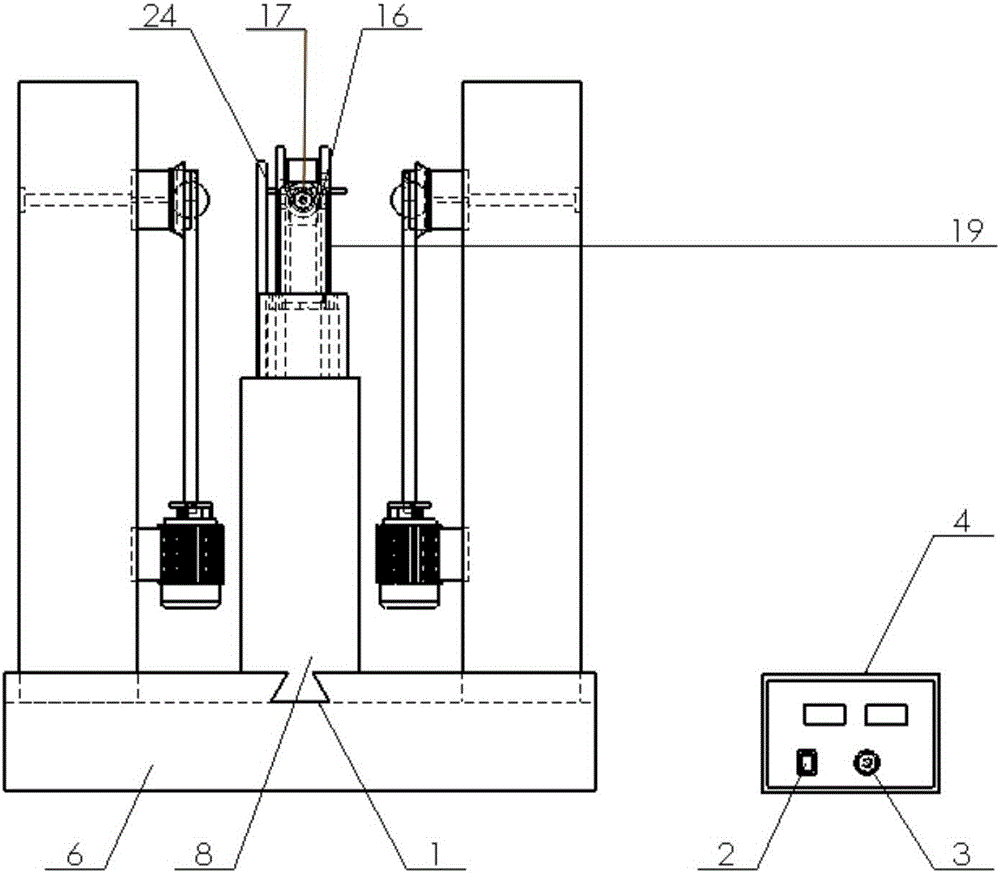

[0046] Such as Figure 1 to Figure 5 As shown, a ball-to-brush batch nanofiber yarn processing device includes a body 23 and a base 6, wherein the base 6 is provided with cross wedge-shaped grooves 1 and 5 in the middle, and the body 23 is along the first A wedge-shaped groove 1 is symmetrically arranged on the second wedge-shaped groove 5, and the body 23 includes a liquid supply system, a separation electric field control system, a spherical brush-type spinning system, a nanofiber yarn forming system and a nanofiber yarn collection system, The liquid supply system includes a gas cylinder 30, a spinning solution storage bottle 34, an oil bath 36 and a catheter 37, the spinning solution storage bottle 30 is arranged in the oil bath 36, and the spinning solution storage The liquid bottle 30 and the liquid guide tube 37 form a connector structure to the brush liquid tank 21. The spinning liquid storage bottle 34 is connected to the gas cylinder 30 through the gas pipe 25. On the...

Embodiment 2

[0075] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 10%. Inject the configured PAN / DMF high polymer solution into the liquid storage bottle 34, and connect the liquid storage bottle 34 and the brush liquid tank 21 through the liquid supply channel 9 with the catheter 37; The position of the second wedge-shaped groove 5 on the nanometer yarn device base 6 of the mount 7 of the silk device 23 makes the distance between the two mounts 20cm; adjust the height of the metal ring 14 of the two spherical spinning devices on the cylinder seat 13 respectively The distance between the top and the top of the spherical nozzle 12 is 40mm; adjust the position of the yarn-forming seat 8 on the first wedge-shaped groove 1 on the base 6 of the nano-yarn device; adjust the height of the metal disc seat 19, and adjust the position of the yarn-drawing hole s...

Embodiment 3

[0077] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 12%. Inject the configured PAN / DMF high polymer solution into the liquid storage bottle 34, and connect the liquid storage bottle 34 and the brush liquid tank 21 through the liquid supply channel 9 with the catheter 37; The position of the second wedge-shaped groove 5 on the nanometer yarn device base 6 of the mount 7 of the silk device 23 makes the distance between the two mounts 20cm; adjust the height of the metal ring 14 of the two spherical spinning devices on the cylinder seat 13 respectively The distance between the top and the top of the spherical nozzle 12 is 40mm; adjust the position of the yarn-forming seat 8 on the first wedge-shaped groove 1 on the base 6 of the nano-yarn device; adjust the height of the metal disc seat 19, and adjust the position of the yarn-drawing hole s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com