A method for iron ore reduction and ironmaking by applying an electric field

An electric field and iron ore technology, applied in the field of electrochemical smelting reduction of iron ore, can solve the problems of poor product quality, huge investment, low production efficiency, etc., and achieve simple device structure, huge social benefits, and zero emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

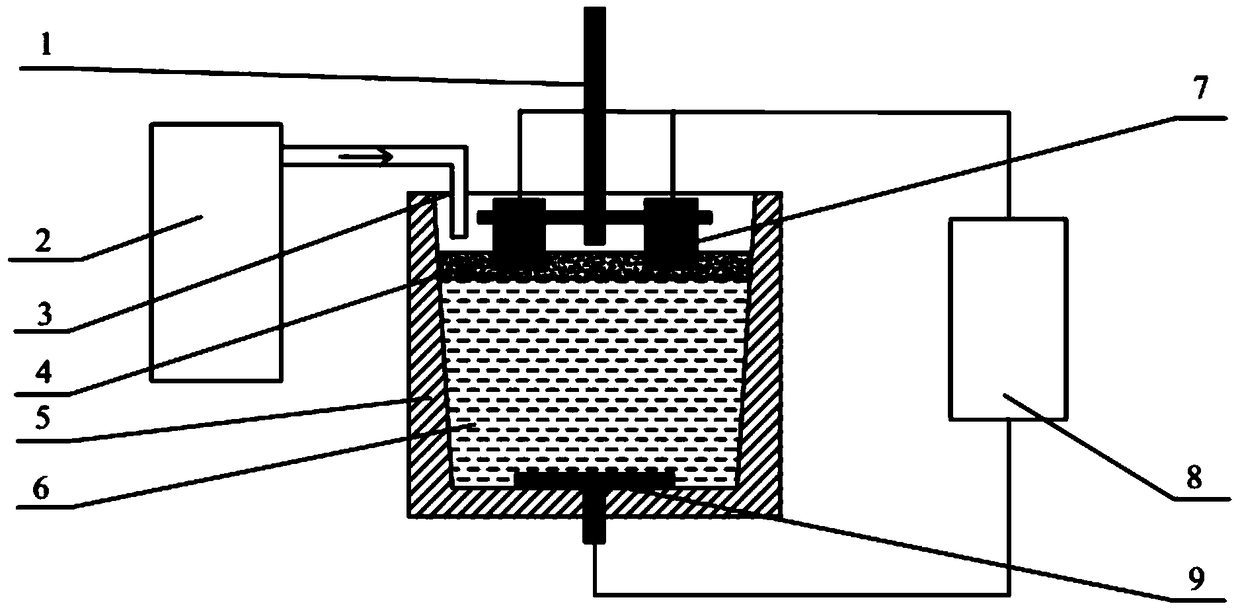

[0039] see figure 1 , the present invention uses an electric field to carry out iron ore reduction and ironmaking equipment comprising: an anode lifting frame 1, a gas supply device 2, 2 protective gas holes 3, a molten electrolyte 4, a heating furnace 5, an iron-carbon metal melt 6, an anode 7, DC power supply 8 and cathode 9. It is characterized in that: there are iron-carbon metal melt 6 and molten electrolyte 4 in the heating furnace 5; the iron-carbon metal melt 6 is placed in the lower layer of the heating furnace 5, and the molten electrolyte 4 is placed in the upper layer; it is set in the middle above the molten electrolyte 4 There is an anode lifting frame 1, on which are installed a number of parallel and vertically arranged anodes 7, the lower end of the anode 7 is inserted into the molten electrolyte 4 in the upper part of the heating furnace 5, and the anode wire is drawn out from the upper part, and the wire is connected with the DC power supply 8 The positive ...

Embodiment 2

[0045] see figure 1 , The iron ore reduction ironmaking device using an electric field in the present invention is as described in Embodiment 1 above, and will not be repeated here.

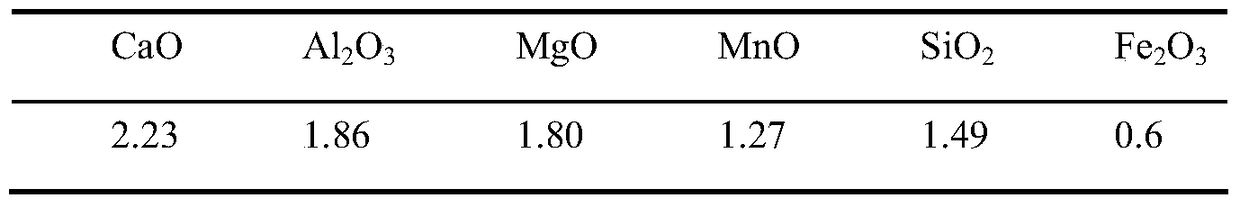

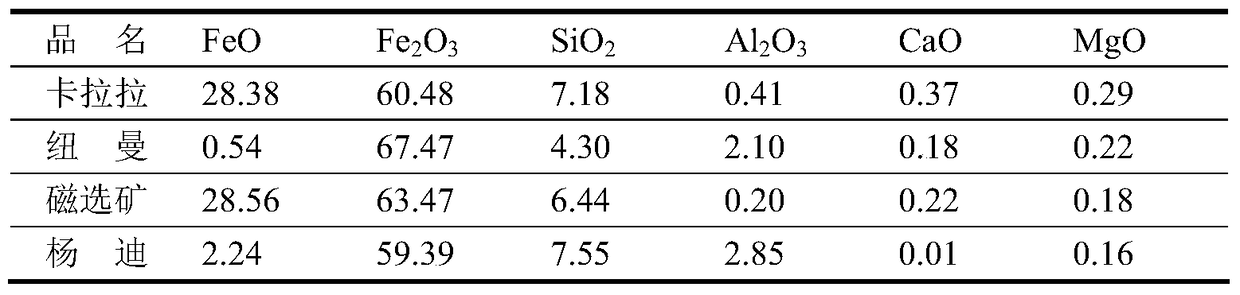

[0046] Described iron ore powder is Newman iron ore powder, and its main composition and content are as shown in table 1; Described slagging agent is small grain lime and bauxite, and the dosage ratio of small grain lime and bauxite is 3:2, Their respective main compositions and contents are shown in Table 2 and Table 3. After mixing, CaO+Al 2 o 3 Reach 89% (mass percentage ratio), and its mass percentage ratio CaO: Al 2 o 3 =1.6, the mass percentage of MgO in the slagging agent is 4.28%, and the rest is SiO 2 ,P 2 o 5 , P, S and other impurities; the ratio of iron ore powder to slagging agent is 0.7; the ratio of iron-carbon metal to electrolyte raw material is 2.

[0047] The output voltage U of the external DC power supply is 5V, the output current I is 400A, and 2.26A / cm can be generat...

Embodiment 3

[0050] see figure 1 , the present invention uses an electric field to carry out iron ore reduction and ironmaking equipment as described in the first embodiment, the difference is that the anode is a high-temperature resistant cermet, the shape is a cylinder, and the diameter is Φ240mm;

[0051] Described iron ore powder is magnetically separated iron ore powder, and its main composition and content are as shown in Table 1; Described slagging agent is small grain lime and bauxite, and the dosage ratio of small grain lime and bauxite is 2:1 , and their respective main compositions and contents are shown in Table 2 and Table 3. After mixing, CaO+Al 2 o 3 Reach 90% (mass percentage ratio), and its mass percentage ratio CaO: Al 2 o 3 =2.1, the mass percentage of MgO in the slagging agent is 4.03%, and the rest is SiO 2 ,P 2 o 5 , P, S and other impurities; the ratio of the iron ore powder to the slagging agent is 0.8; the ratio of the iron-carbon metal to the electrolyte raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com