Railway Express Freight Car Bogie

A technology for express freight cars and bogies, which is applied in the directions of bogies, railway car body parts, devices for lateral relative movement between the underframe and the bogies, etc. problems, to achieve the effect of improving bearing capacity, increasing strength and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

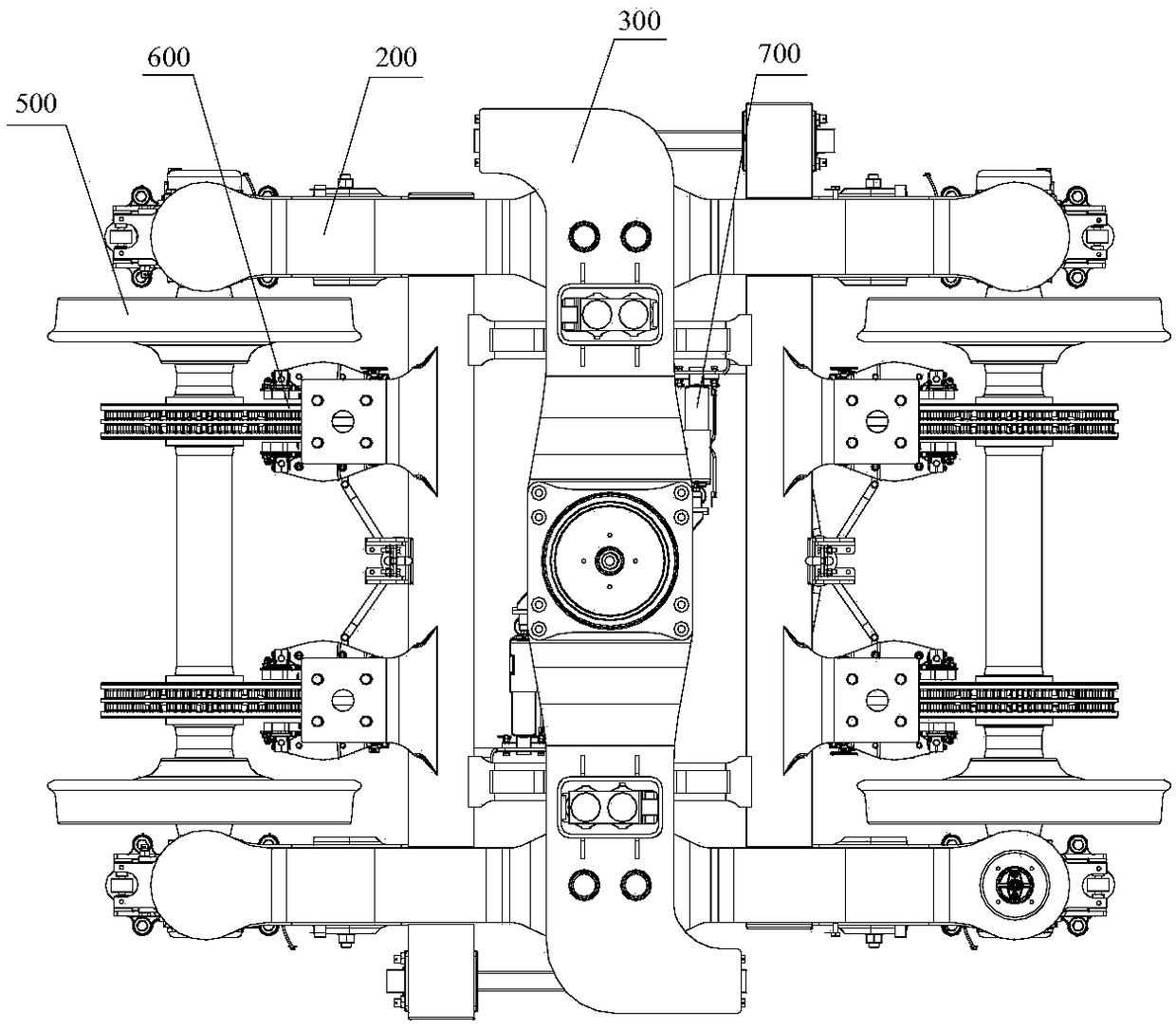

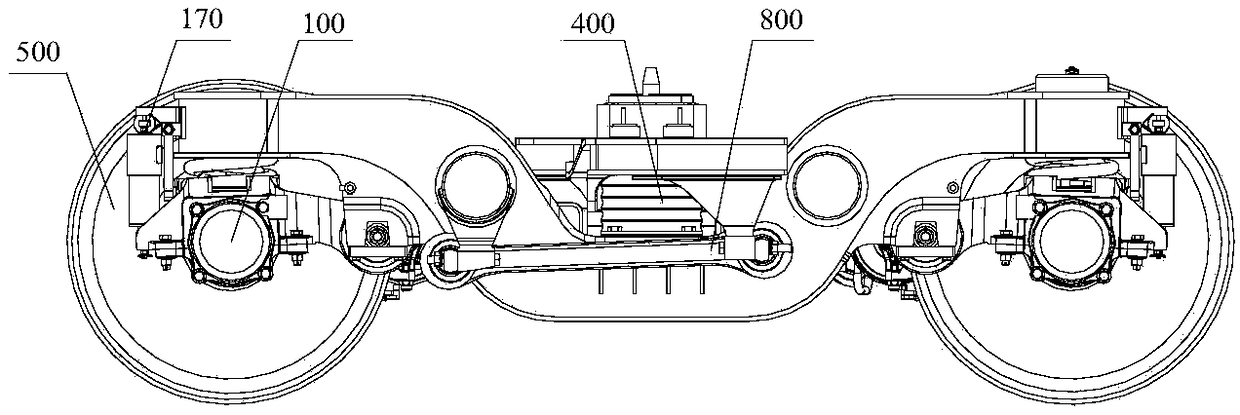

[0059] Such as figure 1 , figure 2 The railway express freight car bogie shown includes a frame 200, four sets of rotary arm axle box positioning devices 100, two sets of wheel sets 500, a bolster 300, and a set of basic braking devices 600.

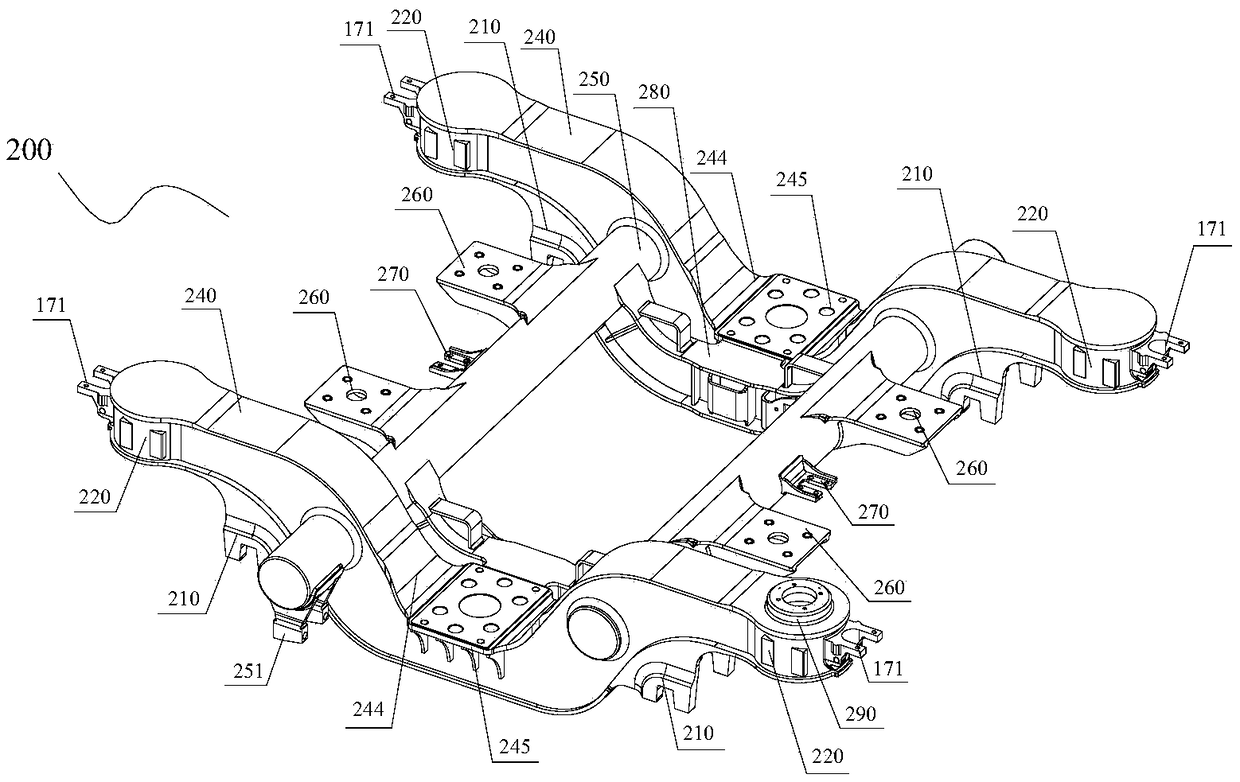

[0060] Such as image 3 As shown, the frame 200 includes a pair of side beams 240 with a double-web box structure, a pair of cross beams 250 with a round steel tube structure, and a pair of arc-shaped longitudinal beams 280. Combine Figure 4 As shown, the side beam 240 includes a side beam double web 241, a side beam upper cover plate 242, and a side beam lower cover plate 243. In this embodiment, the middle part of the side beam 240 is a downwardly concave U-shaped cavity 244. The bottom plane 244a of the U-shaped cavity 244 is welded with a secondary rubber stack installation platform 245, and the secondary r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com