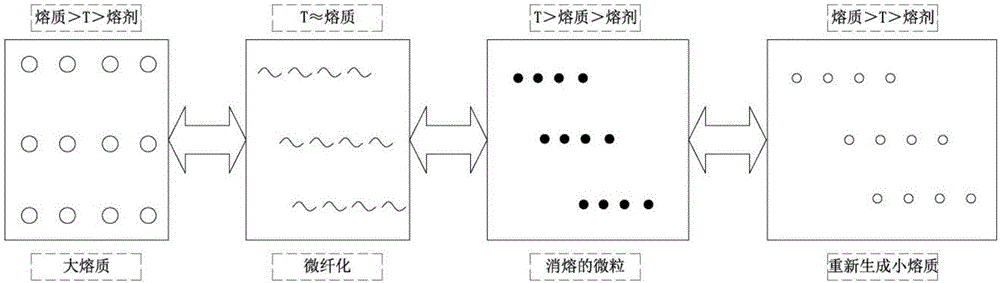

Temperature-dependent phase alternation surface shear plasticization method

An inclined surface and material technology, which is applied in the field of shear plasticizing of temperature-induced intersecting and changing surfaces, can solve the problems of small shear area, weak shearing effect, and low plasticizing pressure, and achieves the improvement of plasticizing effect and mixing degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

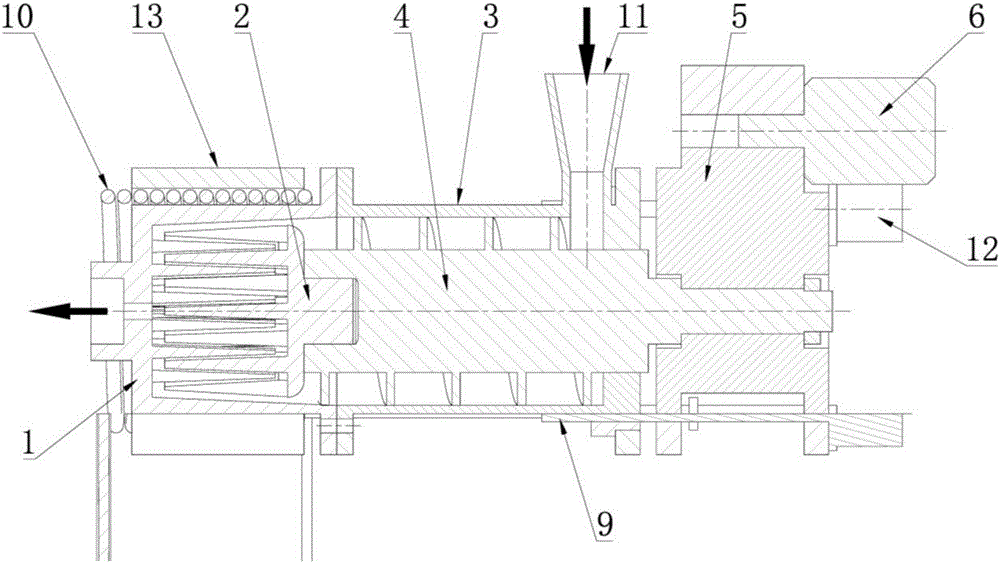

[0045] The selected two-component materials are: α-type polypropylene and high-density polyethylene, with melting points of 150°C and 130°C, respectively.

[0046] The control temperatures of the electromagnetic induction fast heating coil 13 and the circulating cooling coil 10 are 160° C. and 140° C. respectively, that is, the actual temperature alternates between 160° C. and 140° C., and the alternating period is 120 seconds.

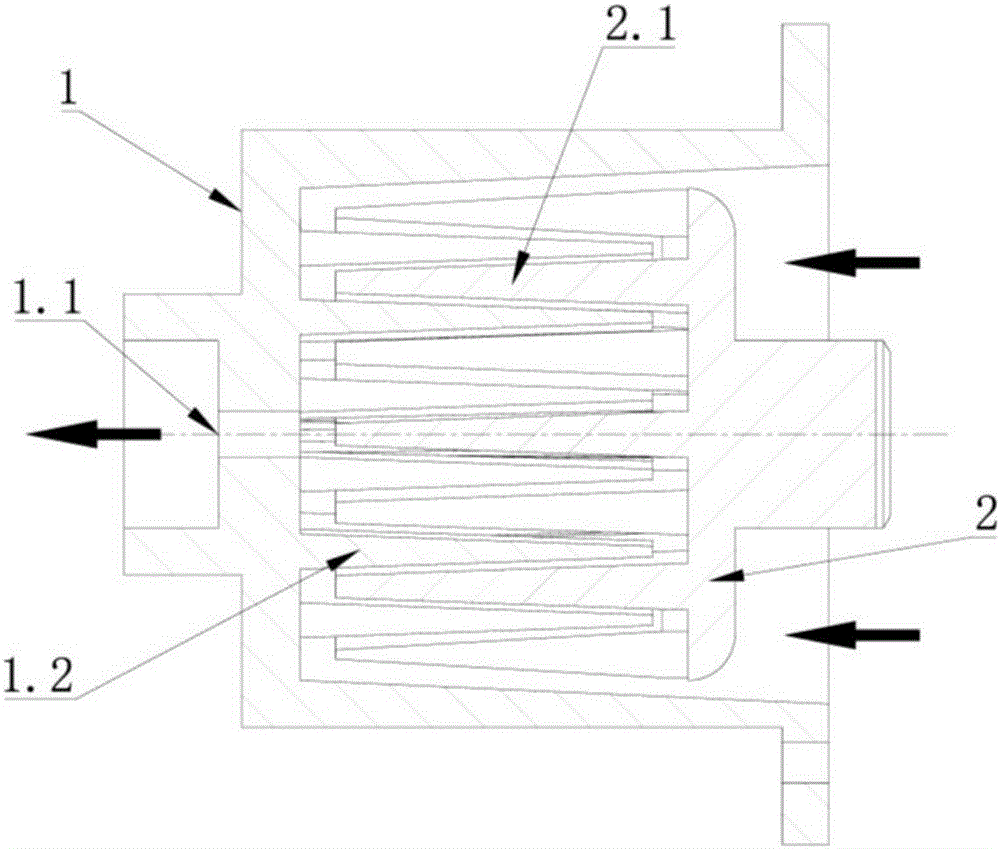

[0047] Inner sleeve 2 has a diameter of 210mm, four layers of cylindrical grinding discs, a layer thickness of 10mm, an inclination of 2°, and a grinding disc length of 170mm. Outer sleeve 1 has a diameter of 260mm, including four layers of cylindrical grinding discs on the outer wall, with a layer thickness of 10mm, an inclination of 2°, and a grinding disc length of 170mm.

[0048] The disc gap is 1mm.

[0049] The outer diameter of the conveying screw 4 is 230mm, the length is 420mm, the screw pitch is 20mm, and the screw groove depth is 6mm. Spe...

Embodiment 2

[0051] The selected two-component materials are: nylon 6 and gamma polypropylene, the melting points are 210°C and 180°C respectively.

[0052] The control temperatures of the electromagnetic induction fast heating coil 13 and the circulating cooling coil 10 are 220° C. and 190° C. respectively, that is, the actual temperature alternates between 220° C. and 190° C., and the alternating period is 150 seconds.

[0053] Inner sleeve 2 has a diameter of 150 mm, three layers of cylindrical grinding discs, layer thickness of 10 mm, inclination of 3°, and grinding disc length of 120 mm. Outer sleeve 1 has a diameter of 200mm, including three layers of cylindrical grinding discs on the outer wall, with a layer thickness of 10mm, an inclination of 3°, and a grinding disc length of 120mm.

[0054] The disc gap is 1.5mm.

[0055] The outer diameter of the conveying screw 4 is 170mm, the length is 320mm, the screw pitch is 20mm, and the screw groove depth is 6mm. Speed 150rpm.

Embodiment 3

[0057] The selected three-component materials are: nylon 6, γ-type polypropylene, and low-density polyethylene, with melting points of 210°C, 180°C, and 135°C, respectively.

[0058] The control temperatures of the electromagnetic induction fast heating coil 13 and the circulating cooling coil 10 are 220° C. and 160° C. respectively, that is, the actual temperature alternates between 220° C. and 160° C., and the alternating period is 150 seconds.

[0059] Inner sleeve 2 has a diameter of 90 mm, two layers of cylindrical grinding discs, a layer thickness of 10 mm, an inclination of 2°, and a grinding disc length of 100 mm. Outer sleeve 1 has a diameter of 140mm, including three layers of cylindrical grinding discs on the outer wall, with a layer thickness of 10mm, an inclination of 2°, and a grinding disc length of 100mm.

[0060] The disc gap is 1.5mm. The number of interlayer material channels is 3, and the channel width is 10mm.

[0061] The outer diameter of the delivery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com