Particle material drying robot

A technology of granular materials and robots, applied in the field of mechanical processing, can solve the problems of increased energy consumption, low drying efficiency, and inability to achieve rapid unloading and quantitative heating, and achieve the effect of enhancing stability and ensuring drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

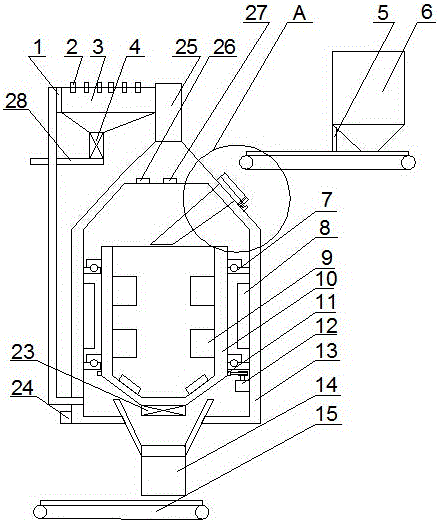

[0039] A granular material drying robot, comprising a feeding mechanism 6, a drying mechanism arranged at the rear of the feeding mechanism 6, a drying mechanism arranged on the upper part of the drying mechanism, and arranged at the rear of the drying mechanism The discharging mechanism, and the control mechanism 24 interconnected with the signal of the feeding mechanism 6, the drying mechanism, the drying mechanism and the discharging mechanism;

[0040] The feeding mechanism includes a feeding conveyor belt 64, a material bin 61 arranged above the rear of the feeding conveyor belt 64, and a material protection plate 63 arranged on both sides of the feeding conveyor belt 64, arranged on the material bin 61 Material limiting plate 5 at the lower outlet;

[0041] The drying mechanism includes a casing 13, a driving motor 12 arranged at the bottom of the casing 13, a drying drum 10 arranged at the top of the driving motor 12, and a stirring blade 9 is arranged in the drying dru...

Embodiment 2

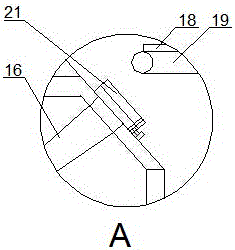

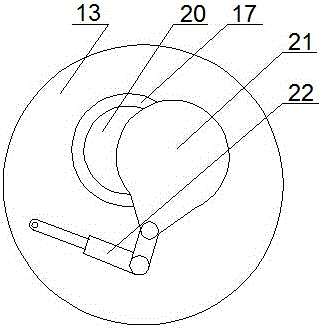

[0053] The upper part of the housing 13 is provided with a shell hole 20 matched with the feeding conveyor belt 64, and a shell cover 21 is arranged on the shell hole 20. The opening and closing of the shell cover 21 is controlled by a hydraulic mechanical arm 22, and the A sealing ring 17 is arranged on the peripheral side of the cover.

[0054] The shell hole 20 is provided for diverting the material to the diversion groove 16 in the clinker cylinder; the rotating bearing 7 is provided with a pressure sensor.

[0055] The rotary bearing used in this embodiment is a thrust bearing, which can ensure that while the mass is carried on it, a pressure sensor can be installed on it to sense the quality change in the drying drum, and the drying mechanism includes a housing, which is arranged on the The driving motor at the lower part of the housing is arranged on the drying cylinder above the driving motor, the stirring blade is arranged in the drying cylinder, and the lower part of...

Embodiment 3

[0057] A stirring roller 62 for preventing material from coagulating is arranged at the outlet of the lower part of the silo 61 , and a stirring column for increasing the stirring function is arranged on the stirring roller 62 .

[0058] The stirring blade 9 is a corrugated blade.

[0059] The outer wall of the drying cylinder 10 is fixed to the casing 13 through the rotating bearing 7 .

[0060] The control mechanism 24 is a microcomputer.

[0061] The drying mechanism adopted in this embodiment includes a drying pipeline arranged on the upper part of the housing, a temperature detection module arranged in the drying pipeline, and a drying module connected with the drying pipeline, and the drying module is arranged at the rear The return pipe connected with the shell; the temperature detection module and the humidity detection module are used to detect the change of the material in the clinker cylinder, which is used as one of the indicators to detect whether the drying is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com