Brand-new fresh-air paper and preparation method thereof

A wind paper and paper technology, applied in the field of full-heat fresh air paper and its preparation, can solve the problems of uneven moisture permeability, air tightness, tear resistance, aging resistance, mildew resistance, and poor control of fiber gaps. Good, not enough to save energy and environmental protection, etc., to achieve the effect of good moisture permeability, good paper evenness, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

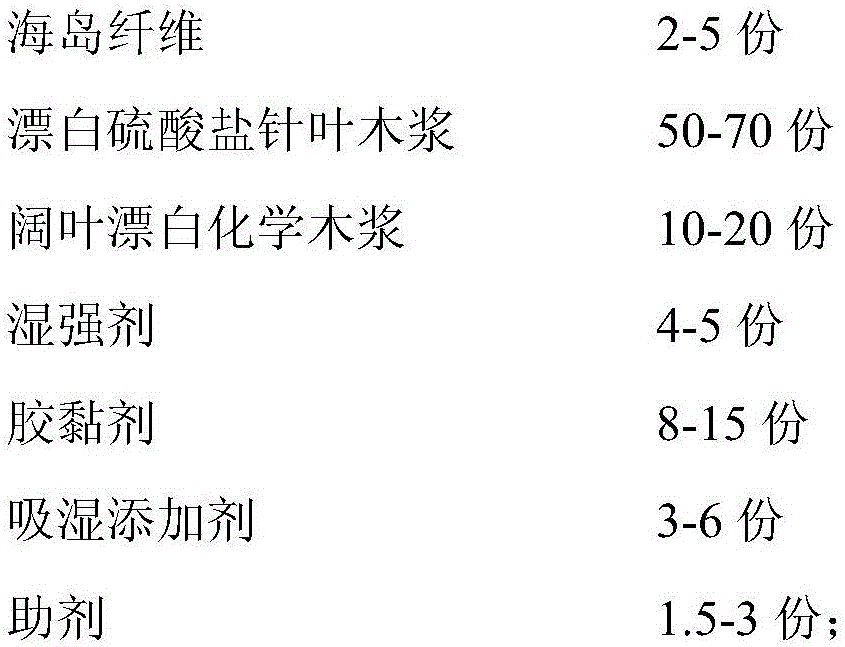

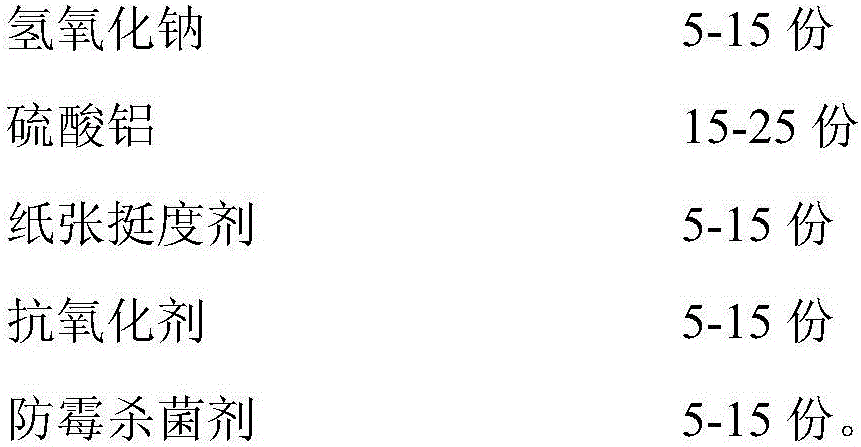

[0061] The composition of raw materials is as follows:

[0062]

[0063] The preparation method is as follows:

[0064] (1) The sea-island fibers are pretreated with sodium hydroxide solution, the concentration of the sea-island fibers is 6%, heated and stirred at 95°C for 30 minutes, and then washed with water for later use. The treatment of the sea-island fibers directly affects the moisture permeability;

[0065] (2) After the sea-island fiber after treatment, bleached kraft softwood pulp, and broadleaf bleached chemical wood pulp are mixed, they are put into a beater and diluted with water for beating, and the beating degree is 24.5 ° SR to obtain a slurry;

[0066] (3) Mix the slurry obtained in step (2) with wet strength agent PAE, paper stiffness agent methyl methacrylate, antifungal and fungicide isothiazolinone derivatives, aluminum sulfate, stir and mix for 1 hour, and mix The slurry is copied and dried by an inclined wire paper machine to obtain semi-finished ba...

Embodiment 2

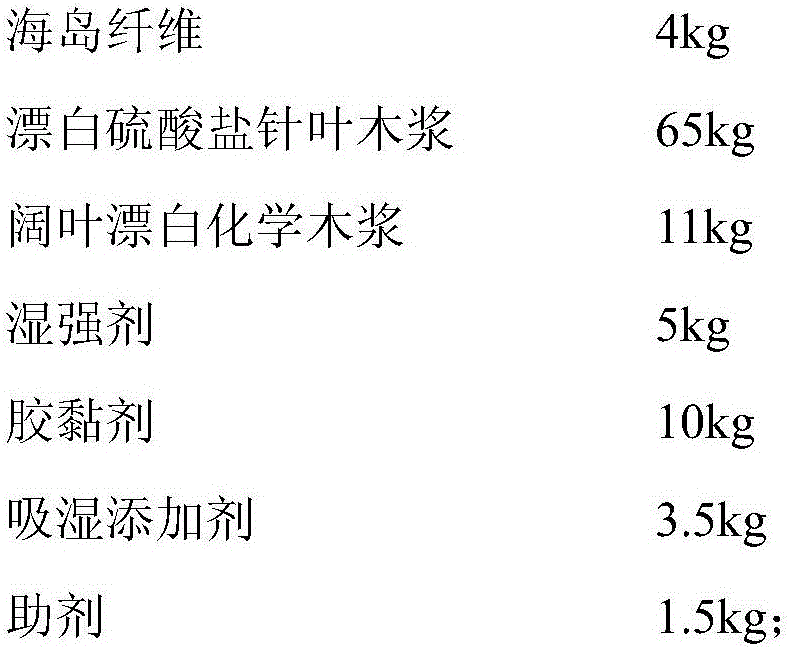

[0076] The composition of raw materials is as follows:

[0077]

[0078] The preparation method is as follows:

[0079] (1) The sea-island fibers are pretreated with sodium hydroxide solution, the concentration of the sea-island fibers is 3%, heated and stirred at 95°C for 30 minutes, and then washed with water for later use. The treatment of the sea-island fibers directly affects the moisture permeability;

[0080] (2) After the sea-island fiber, bleached kraft softwood pulp, and broadleaf bleached chemical wood pulp are mixed, they are put into a beater and diluted with water for beating, and the beating degree is 23 ° SR to obtain a slurry;

[0081] (3) Mix the slurry obtained in step (2) with wet strength agent PAE, paper stiffness agent butyl methacrylate, antifungal and fungicide isothiazolinone derivatives, aluminum sulfate, stir and mix for 2 hours, and mix The slurry is copied and dried by an inclined wire paper machine to obtain semi-finished base paper;

[0082...

Embodiment 3

[0091] The composition of raw materials is as follows:

[0092]

[0093] The preparation method is as follows:

[0094] (1) The sea-island fibers are pretreated with sodium hydroxide solution, the concentration of the sea-island fibers is 7%, heated and stirred at 95°C for 30 minutes, and then washed with water for later use. The treatment of the sea-island fibers directly affects the moisture permeability;

[0095] (2) After the sea-island fiber, bleached kraft softwood pulp and broadleaf bleached chemical wood pulp are mixed, they are put into a beater and diluted with water for beating, and the beating degree is 27 ° SR to obtain a slurry;

[0096] (3) Mix the slurry obtained in step (2) with wet strength agent PAE, paper stiffness agent methyl methacrylate and butyl methacrylate, antifungal and fungicide isothiazolinone derivatives, and aluminum sulfate , after stirring and mixing for 1.5 hours, the mixed slurry was made and dried by an inclined wire paper machine to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com