Electrolysis device for producing hydrogen through water electrolysis and method of electrolysis device

An electrolysis device, water electrolysis technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of accelerated creep speed, difficulty in relaxing relaxation, increased brightness of creep deformation, etc., to reduce energy consumption and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

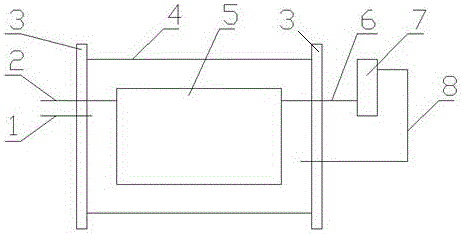

[0027] In order to overcome the problem of insufficient sealing technology of the existing medium-pressure water electrolysis hydrogen production electrolyzer, this embodiment provides a method such as figure 1 The shown water electrolysis hydrogen production electrolysis device includes an electrolysis cell 5, the outside of the electrolysis cell 5 is covered with a cylinder 4, an oxygen outlet pipe 1 is arranged in the cavity between the cylinder 4 and the electrolysis cell 5, and the electrolysis cell 5 is connected with a hydrogen outlet pipe 2.

[0028] Both ends of the cylinder 4 are respectively connected with end plates 3 , and both the oxygen outlet pipe 1 and the hydrogen outlet pipe 2 pass through the end plates 3 and are connected to the outside of the cylinder 4 .

[0029] The outside of the cylinder 4 is provided with a steam-water separator 7, and the steam-water separator 7 is connected with an oxygen balance tube 1 6 and an oxygen balance tube 2 8, and the oxy...

Embodiment 2

[0036] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the water electrolysis hydrogen production electrolysis device shown, the cylinder 4 adopts a cylindrical structure formed by integral welding, the electrolytic cell is placed inside the sealed cylinder, and the two ends of the cylinder are sealed with end plates to form only two sealing surfaces. It solves the problem of many sealing surfaces and poor sealing effect of crude oil equipment. Since the strength of the sealed end plate is high, the end plate 3 is made of high-strength carbon steel plate, and the strength of the end plate 3 is determined according to the design pressure.

[0037] Both ends of the cylinder 4 are welded with flanges, and the flanges are sealed with the end plate 3, which can be completed by traditional flange sealing, and the sealing effect can reach more than 10 MPa.

[0038]In order to further increase the sealing effect, gaskets are provided between the flanges a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com