Graphene-based ternary composite wave-absorbing material and preparation method thereof

A composite absorbing material, alkene-based ternary technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of absorbing strength and absorbing frequency band density, etc., achieve absorbing frequency bandwidth, reduce electromagnetic radiation, The effect of improving the absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

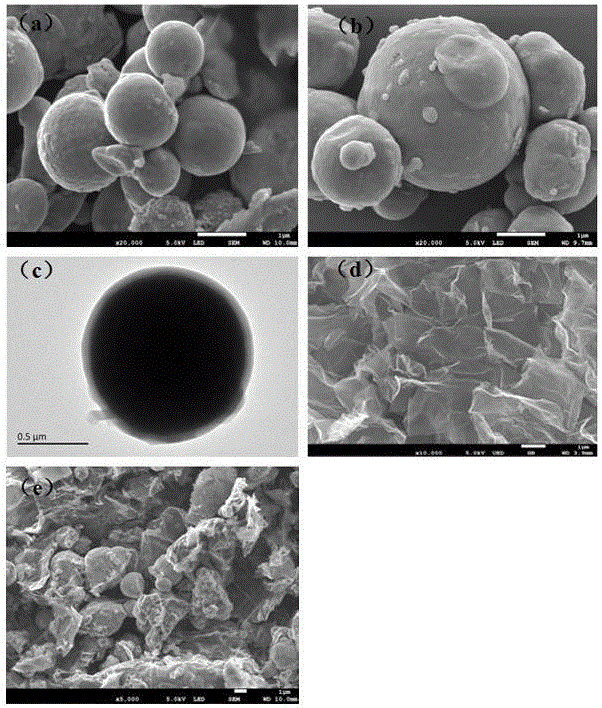

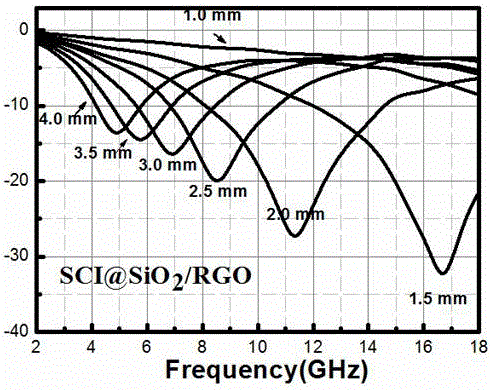

[0037] A preparation method of a graphene-based ternary composite wave-absorbing material, comprising the steps of:

[0038] (1) Preparation of silica-coated iron carbonyl core-shell composite particles

[0039] Add 2g of spherical carbonyl iron to a mixed solution of 160mL of absolute ethanol and 40mL of deionized water, ultrasonically and mechanically stir for 1h, then add 4mL of ammonia water and 4mL of ethyl orthosilicate to the mixed solution, at a reaction temperature of 40°C Mechanically stirred and reacted for 21 hours. After the reaction was completed, suction filtered and washed the product with deionized water and absolute ethanol until the filtrate was colorless, and dried at 40°C for 24 hours to obtain spherical carbonyl iron core-shell composite particles coated with silica. (SCI@SiO 2 ).

[0040] (2) Preparation of graphite oxide

[0041] Using natural flake graphite as raw material, graphite oxide was prepared by the improved Hummers method; the prepared gra...

Embodiment 2

[0047] A preparation method of a graphene-based ternary composite wave-absorbing material, comprising the steps of:

[0048] (1) Preparation of silica-coated iron carbonyl core-shell composite particles

[0049] Add 2g of flaky iron carbonyl to a mixed solution of 160mL of absolute ethanol and 40mL of deionized water, ultrasonically and mechanically stir for 1h, then add 4mL of ammonia water and 4mL of ethyl orthosilicate to the mixed solution, at a reaction temperature of 40°C Under mechanical stirring, react for 21 hours. After the reaction, filter with suction and wash the product with deionized water and absolute ethanol respectively until the filtrate is colorless, and dry at 40°C for 24 hours to obtain a silica-coated flaky carbonyl iron core-shell Composite particles (FCI@SiO 2 ).

[0050] (2) Preparation of graphite oxide

[0051] Using natural flake graphite as raw material, graphite oxide was prepared by the improved Hummers method; the prepared graphite oxide was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com