Dynamically adjustable oil volume immersion oil cooling structure and cooling method in hub motor cavity

A technology of in-wheel motor and cooling structure, applied in electric components, cooling/ventilation devices, electromechanical devices, etc., can solve the problems of limited heat dissipation effect of heat transfer oil, affecting motor efficiency, slow rotor speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

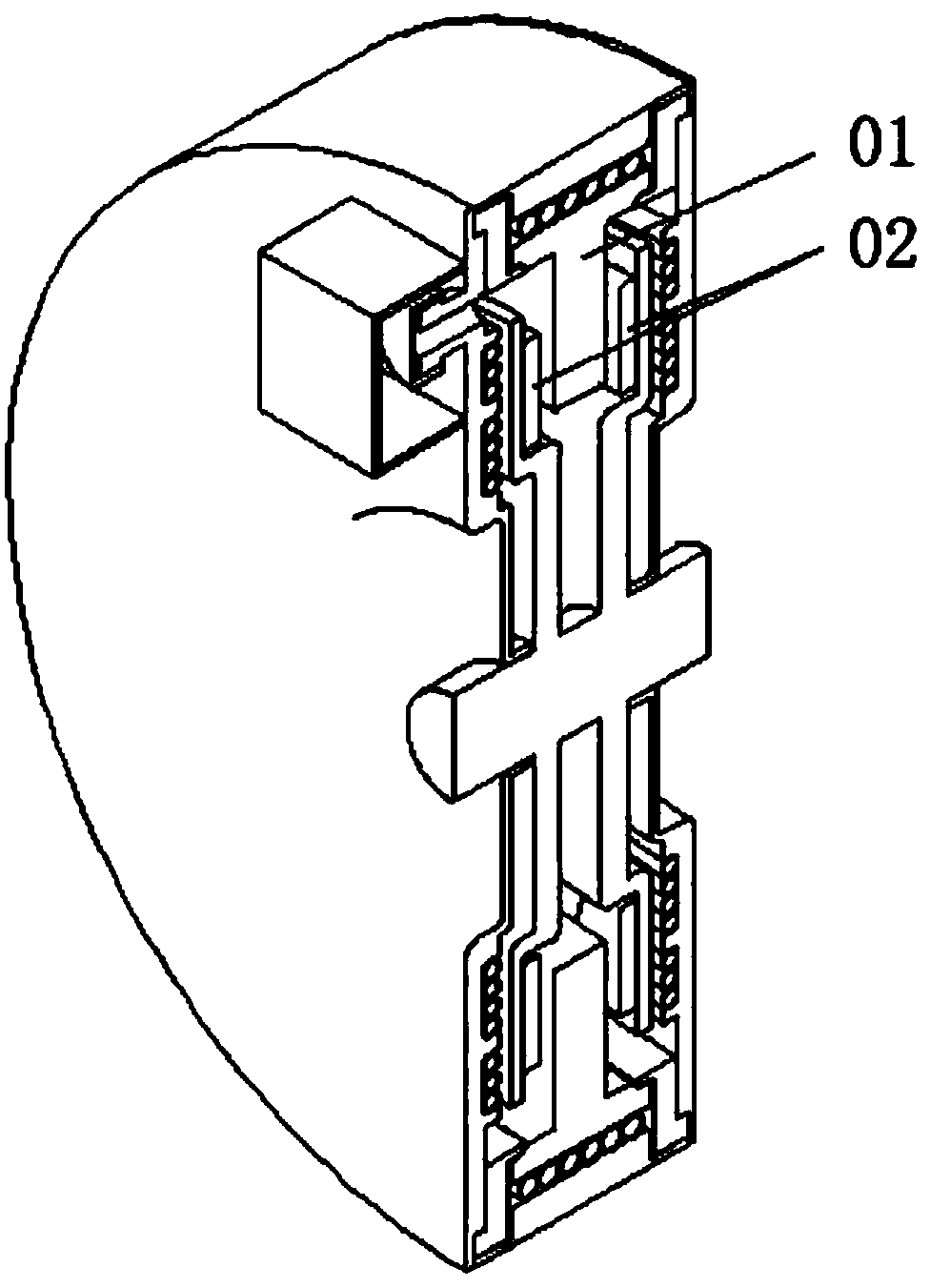

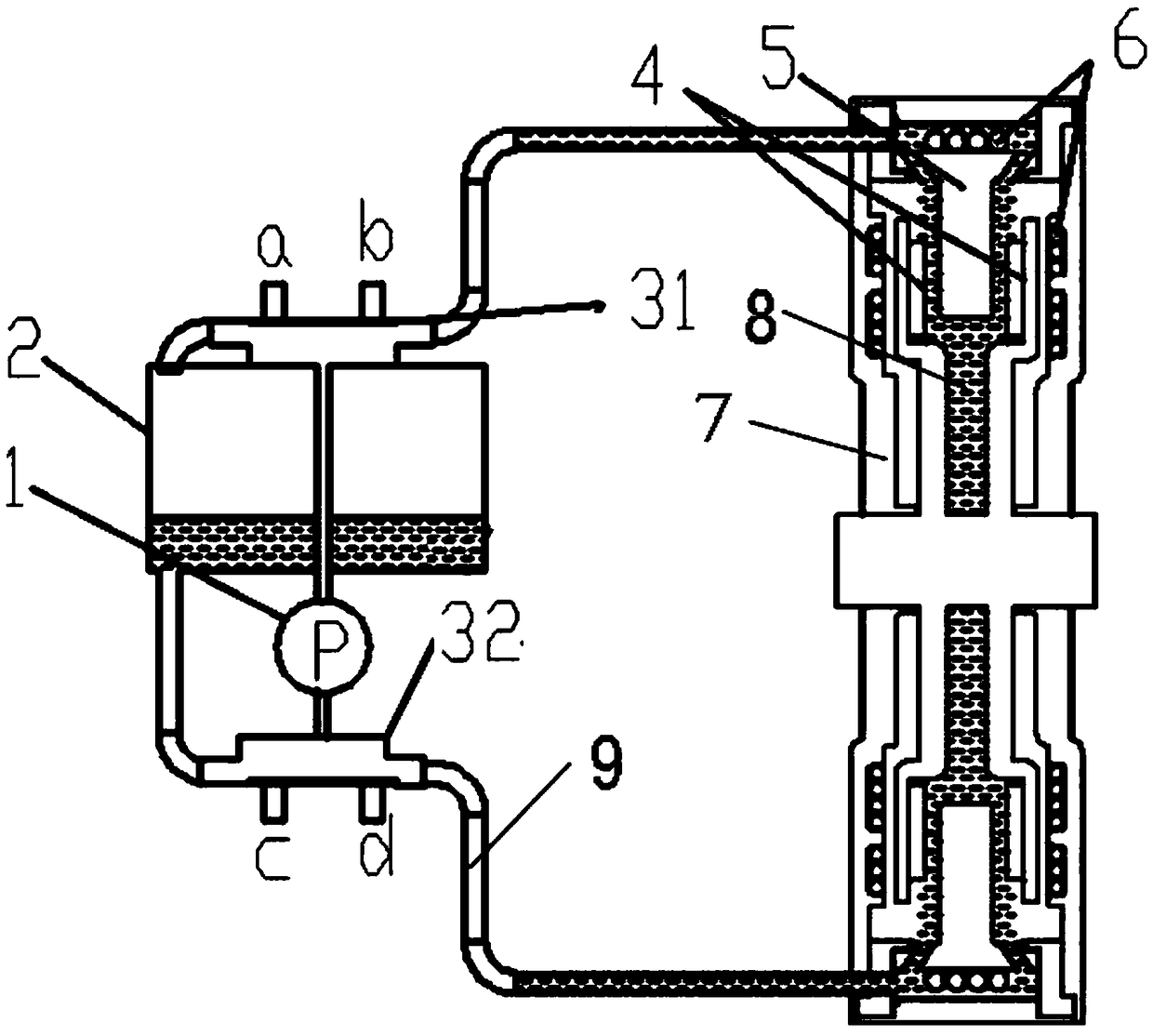

[0020] Embodiment 1: An oil-immersed cooling structure with dynamically adjustable oil volume in the hub motor cavity.

[0021] refer to figure 2 As shown, a dynamic adjustable oil volume immersion oil cooling structure in the hub motor cavity, including: a motor casing 7; a stator coil 5 installed inside the motor casing 7; and a stator coil 5 installed inside the motor casing 7 and capable of rotating The rotor 4; the water cooling jacket 6 is installed between the motor casing 7 and the stator coil 5, the oil guide chamber 8 is arranged between the stator coil 5 and the rotor 4, and the upper end of the oil guide chamber 8 passes through the oil guide pipe 9 Connected to the outlet of the oil passage of the first reversing valve 31, the inlet of the oil passage of the first reversing valve 31 is connected to the oil storage box 2 through the oil guide pipe 9; the lower end of the oil guide chamber 8 is connected to the The outlet of the oil passage of the second reversing...

Embodiment 2

[0026] Embodiment 2: A method for immersion oil cooling with dynamically adjustable oil volume in the hub motor cavity.

[0027] The present invention also provides a cooling method based on the oil immersion cooling structure with dynamically adjustable oil volume in the hub motor cavity in Embodiment 1, which specifically includes the following steps:

[0028] S1. When the motor starts from standstill, stalls or climbs slowly, the speed detector detects that the running speed of the rotor 4 is lower than the set value, the oil pump 1 starts, and the c-position conduction port of the second reversing valve 32 and the first The b-position conduction port of the reversing valve 31 is conducted, the a-position conduction port of the first reversing valve 31 and the d-position conduction port of the second reversing valve 32 are closed, and the oil pump 1 draws oil from the oil storage box 2 , pumped into the oil guide chamber 8 of the motor, when the liquid level detector detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com