Method for improving multiplication cycle performance of lithium battery

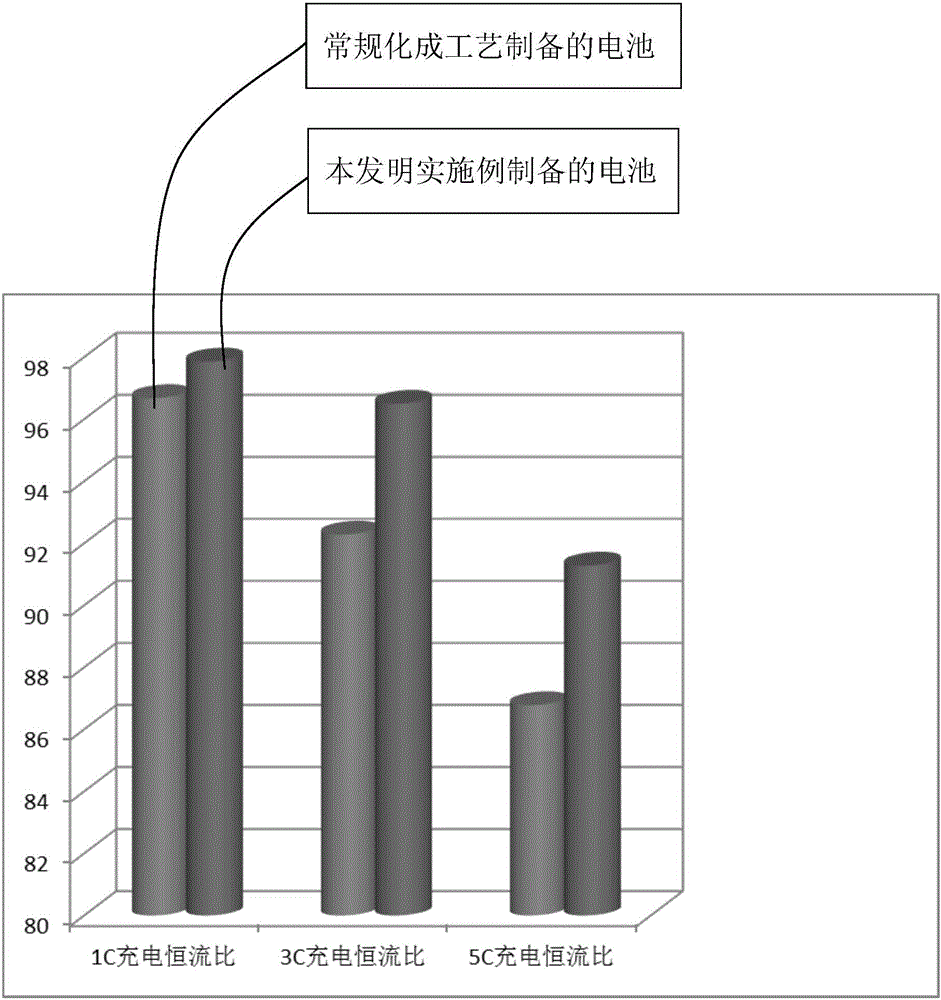

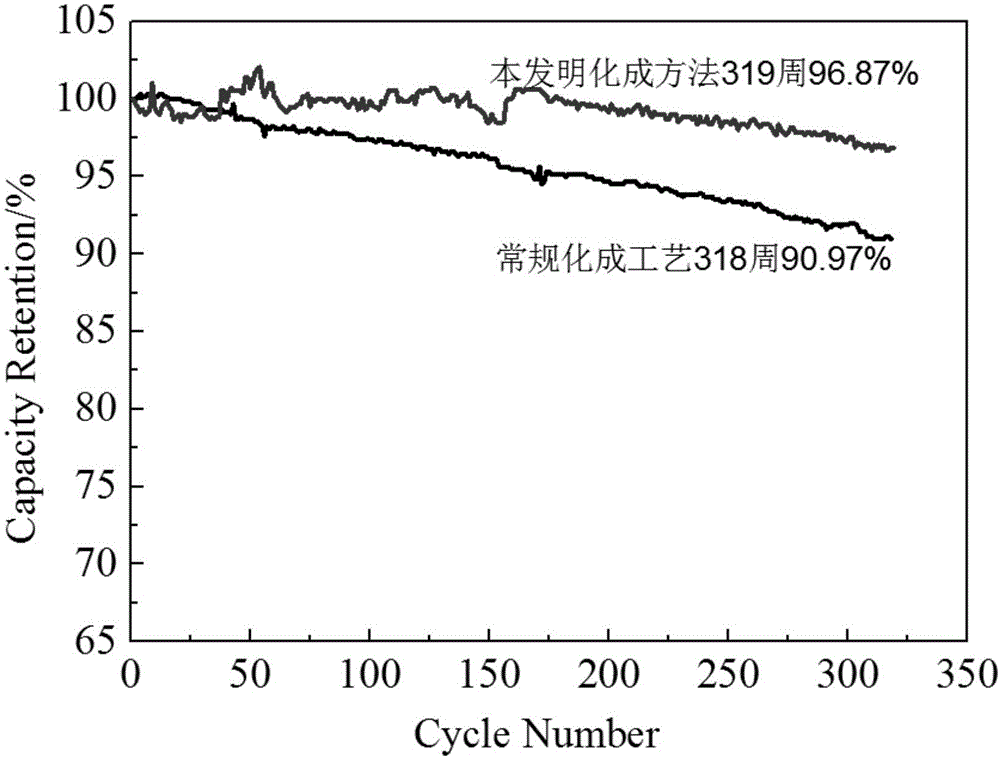

A cycle performance, lithium battery technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, secondary battery charging/discharging, etc., can solve the problems of high AC impedance growth ratio, easy structure collapse, fast capacity decay, etc., to achieve improvement Large-rate charge-discharge performance and high-rate cycle performance, saving production costs, and improving capacity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] (1) Inject the electrolyte into the battery and let it stand for 50 hours, then put it aside for 12 hours at -5°C, so that the internal temperature of the battery is also -5°C;

[0038] (2) After charging with a current of 0.03C to reach 15% SOC, transfer to an environment of 15°C, and leave the battery for 12 hours, so that the internal temperature of the battery is also 15°C;

[0039] (3) Use 0.06C current charging to make the battery reach 35% SOC;

[0040] (4) Charge with 0.2C current to make the battery reach 85% SOC, place the battery at 40°C for 85 hours so that the internal temperature of the battery is also 40°C;

[0041] (5) Finally, in an environment of 15°C, 4 cycles of charge and discharge are carried out with a current of 0.8C to fully activate the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com