A power battery system balance control method and system

A power battery and system equalization technology, applied in secondary batteries, battery circuit devices, secondary battery repair/maintenance, etc., can solve the problems of high cost and low efficiency, reduce design and production costs, simplify circuit design, The effect of saving maintenance time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

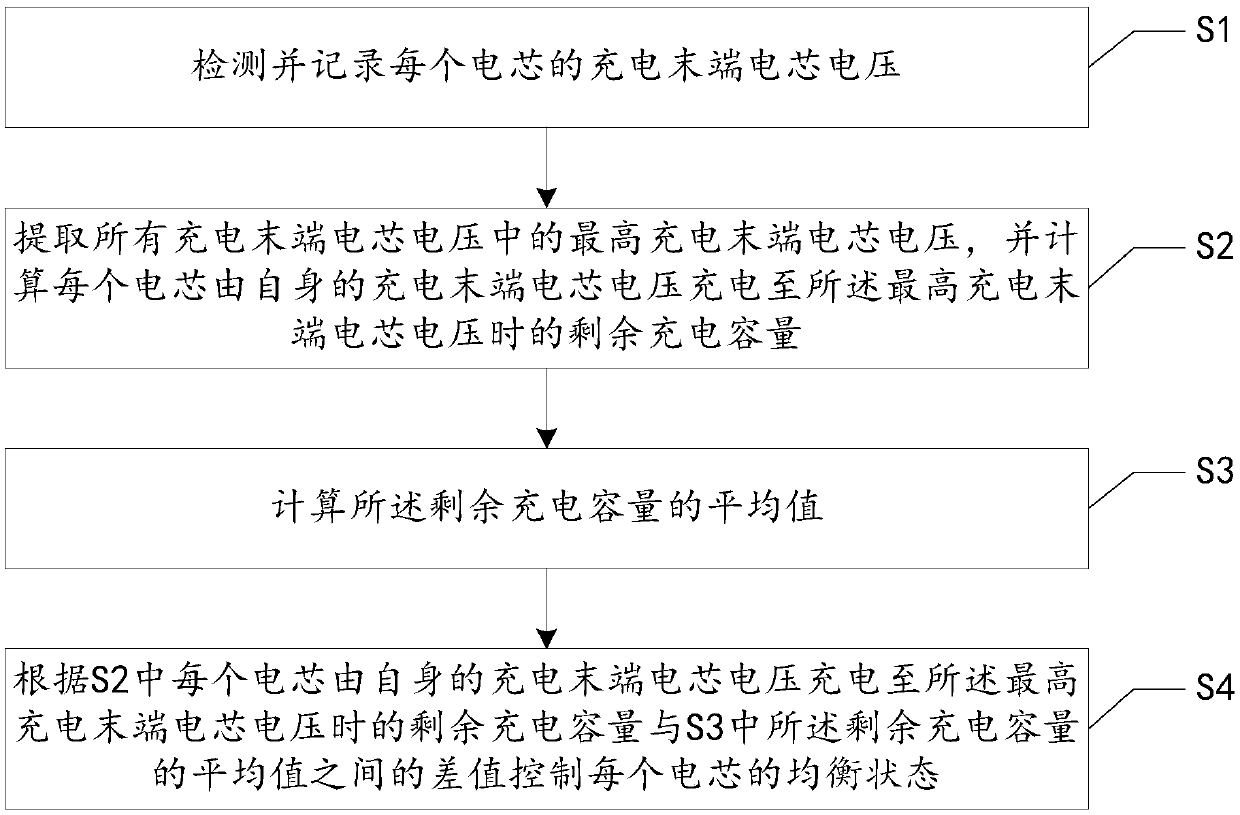

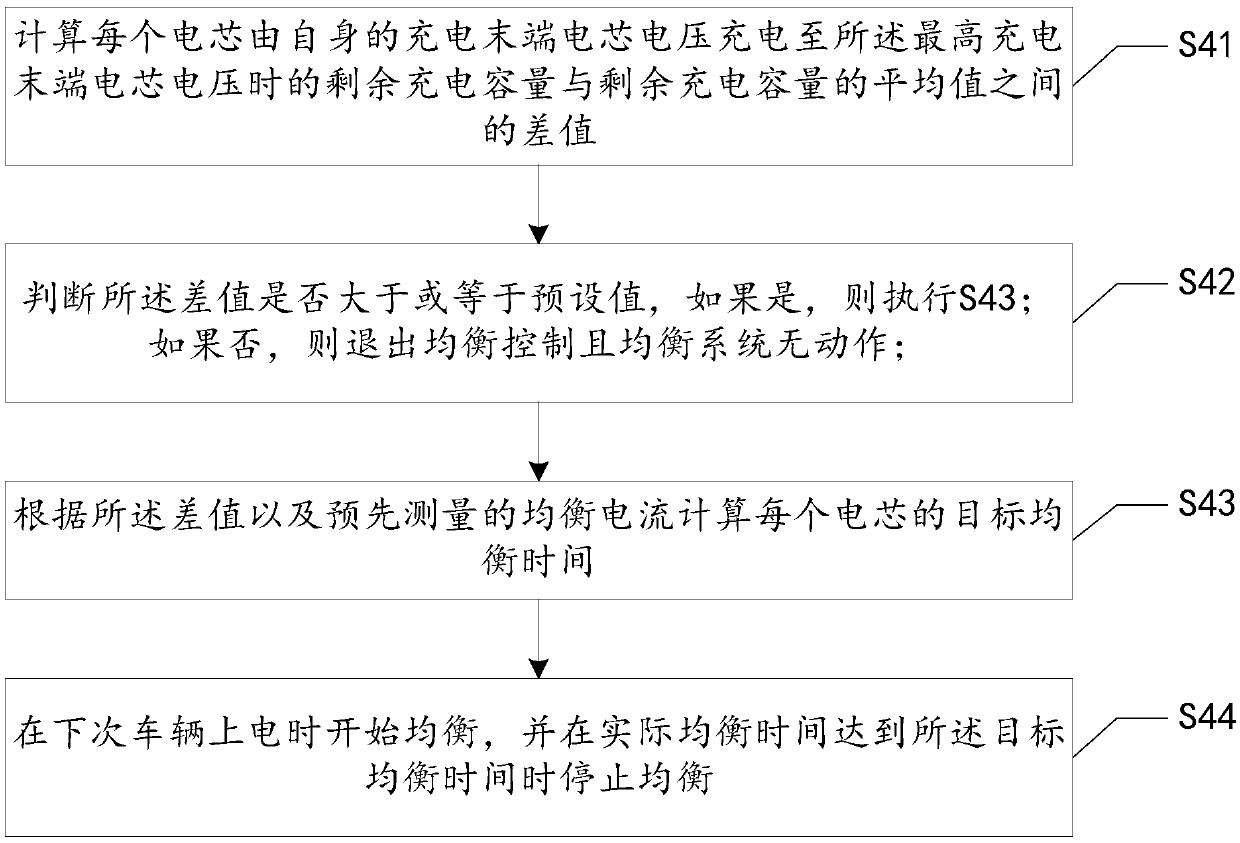

[0050] like figure 1 As shown, this embodiment proposes a power battery system balance control method, the method includes:

[0051] S1. Detect and record the cell voltage at the charging end of each cell.

[0052] Specifically, detect the charging end cell voltage V 1 , V 2 ...V n , where the highest voltage is the cell p, 1≤p≤n, the charging terminal voltage is V p , and for the highest cell p, the voltage V 1 , V 2 ...V p ...V n time t 1 , t 2 ,... t p ... t n , and the rated capacity of the battery system is C 0 .

[0053] S2. Extract the highest charging end cell voltage among all charging end cell voltages, and calculate the remaining charging capacity of each cell when it is charged from its own charging end cell voltage to the highest charging end cell voltage.

[0054] Specifically, calculate V 1 , V 2 ...V p-1 , V p+1 ...V n charge to V p Remaining charge capacity, for example, cell 1 by voltage V 1 charge to V p The remaining charge capacity is ...

corresponding Embodiment 1

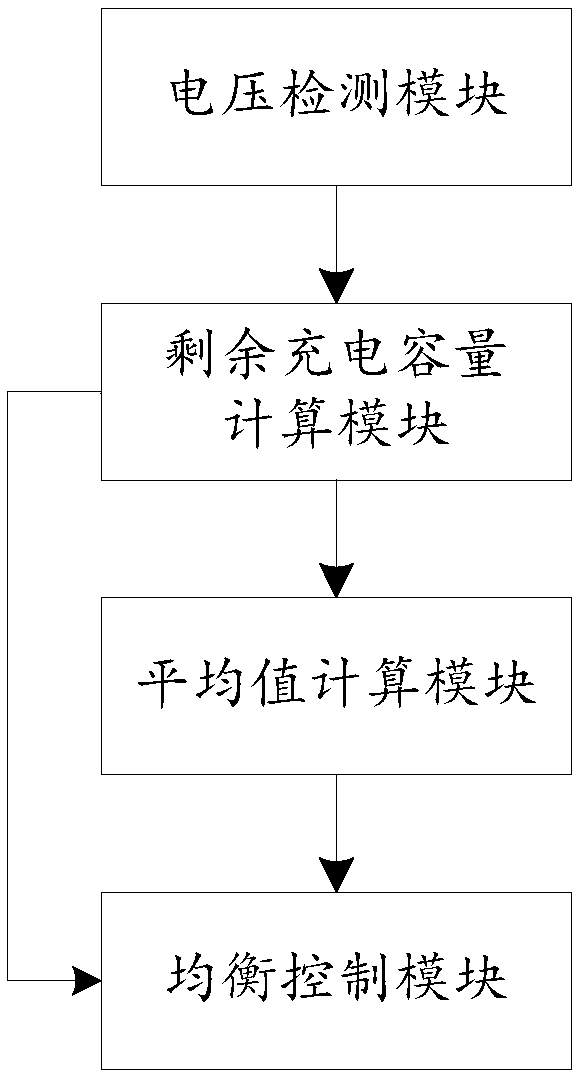

[0067] Corresponding to Embodiment 1, this embodiment proposes a power battery system balance control system, such as image 3 As shown, the system includes:

[0068] The voltage detection module is used to detect and record the battery cell voltage at the charging end of each battery cell;

[0069] The remaining charging capacity calculation module is used to extract the highest charging end cell voltage among all charging end cell voltages, and calculate the time when each cell is charged from its own charging end cell voltage to the highest charging end cell voltage remaining charge capacity;

[0070] an average value calculation module, configured to calculate the average value of the remaining charging capacity;

[0071] The balance control module is used to calculate the remaining charging capacity in the remaining charging capacity calculation module according to the remaining charging capacity and the average value of each battery cell in the remaining charging capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com