A device and method for reducing contact bounce for a vacuum circuit breaker

A vacuum circuit breaker and contact bouncing technology, applied in high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc., can solve the problems of decreasing closing speed and increasing bouncing time, so as to reduce the degree of bouncing and reduce the The effect of contact bouncing and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The device for reducing contact bouncing of the vacuum circuit breaker according to the present invention is preferably implemented in the following manner:

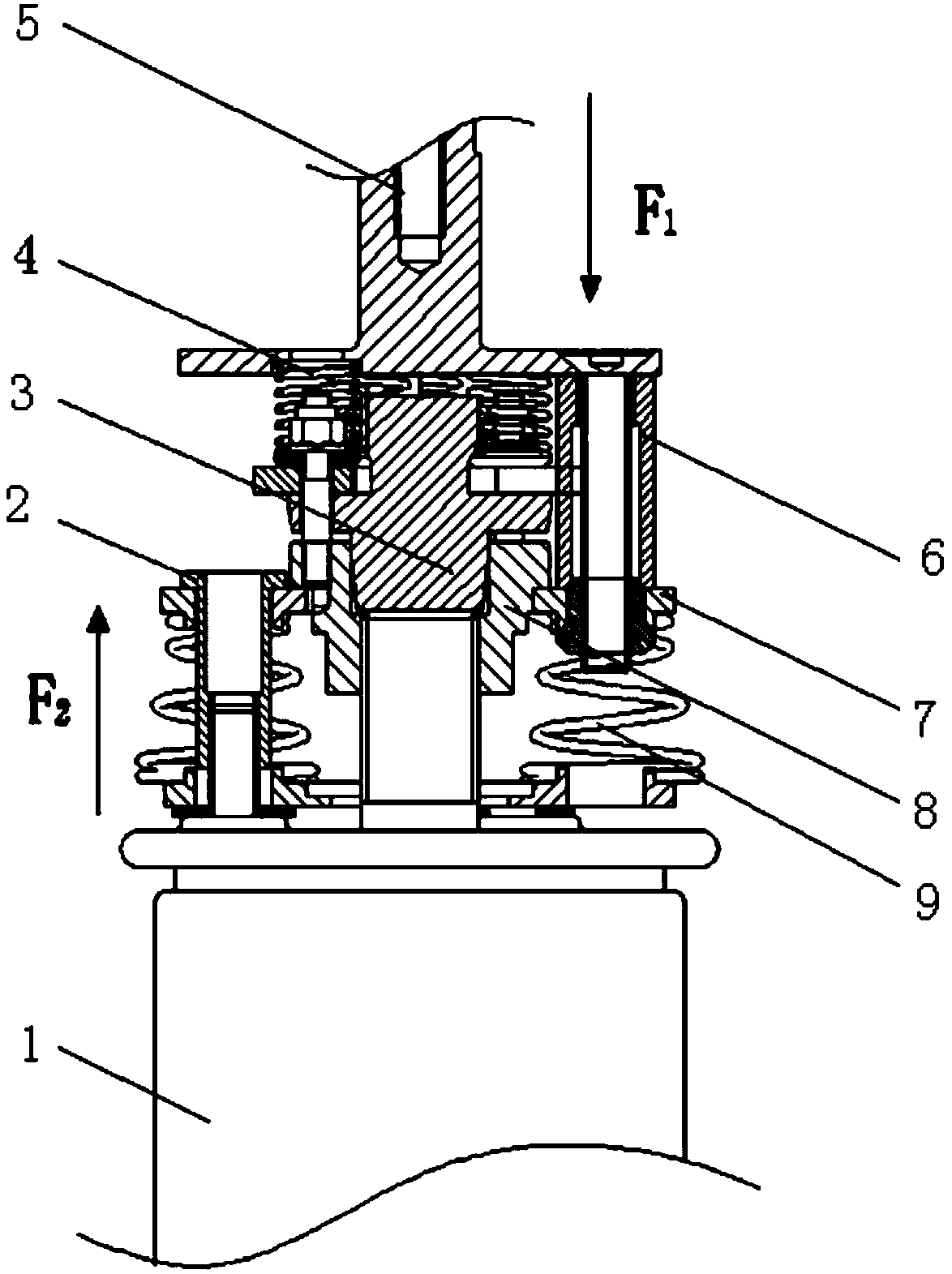

[0018] Including vacuum tube, limit sleeve, connection block, overtravel spring, transmission disc, spacer column, spring seat, compression ring and return spring;

[0019] The return spring is installed on the upper end surface of the vacuum tube through the limiting sleeve and the spring seat, the pressing ring is installed above the spring seat and connected to the vacuum tube at the same time, and the connecting ring is sequentially installed above the pressing ring. block and an overtravel spring, and the drive plate is fastened to the spring seat through the spacer column and bolts while positioning the overtravel spring.

[0020] The return spring includes any one of the following: conical springs, variable stiffness springs, variable wire diameter springs, and multiple sets of cylindrical nested springs. ...

specific Embodiment

[0027] Such as figure 1 As shown, the device for reducing contact bounce of the vacuum circuit breaker of the present invention includes a vacuum tube 1, a limit sleeve 2, a connecting block 3, an overtravel spring 4, a transmission disc 5, a spacer column 6, a spring seat 7, a pressing Ring 8 and return spring 9; wherein, the upper end surface of vacuum tube 1 is installed with return spring 9 through the limit sleeve 2 and spring seat 7, and the pressing ring 8 is installed on the top of spring seat 7 while connecting the moving contact of vacuum tube 1, spring seat 7 and The compression rings 8 can slide relative to each other, and the connection block 3 and the overtravel spring 4 are sequentially installed on the top of the compression ring 8. The lower end surface of the connection block 3 is in close contact with the upper end surface of the moving contact of the vacuum tube 1, and the transmission disc 5 is positioned on the overtravel spring 4 At the same time, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com