Steel plate surface defect image extraction method

An extraction method and surface image technology, applied in image enhancement, image analysis, image data processing, etc., can solve problems such as low contrast, unclear edges, and reduced efficiency and accuracy of defect areas, so as to weaken the influence of noise and avoid errors Extractable, easy-to-handle effects for real-time processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

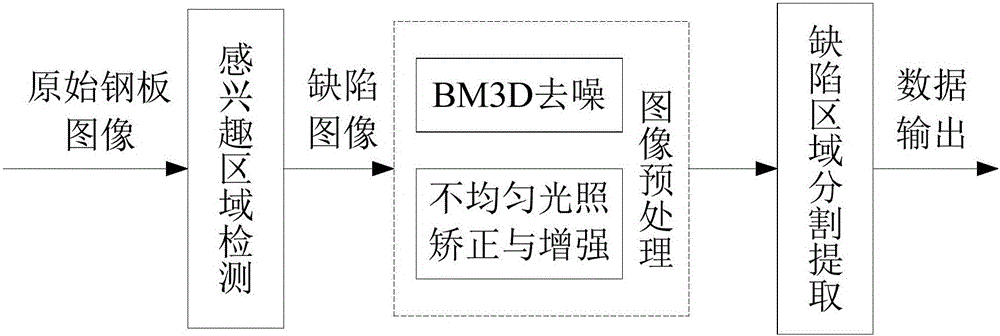

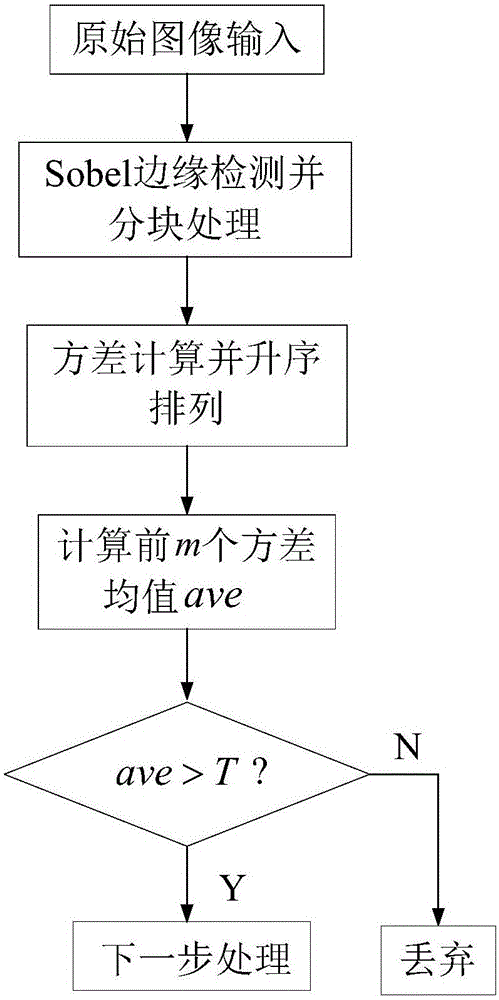

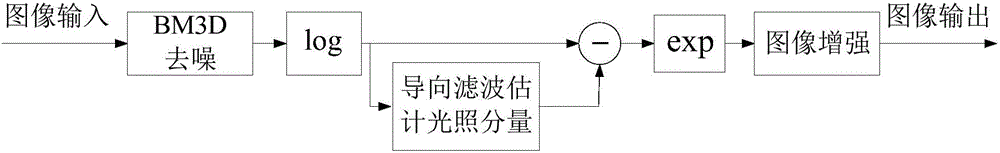

Method used

Image

Examples

Embodiment

[0093] Such as Figure 5 Shown is the original defect image preprocessed by the present invention, wherein, (a) scratches; (b) pressed dirt; (c) holes; (d) black spots; (e) pinholes; (f) scratches mark. The defect image extracted by the extraction method of the present invention is as follows: Image 6 As shown, among them, (a) scratches; (b) press-in dirt; (c) holes; (d) black spots; (e) pinholes; (f) scratches.

[0094] Specifically, take the use of pressed-in dirt defects as an example (such as Figure 7 shown), the parameter settings are selected as follows: in step S11, the number of blocks is 8×8, that is, n is 8; the area occupied by each defect generally does not exceed 20% of the steel plate image area, so m is selected as 12; step S22 Among them, β is that scale factor is selected 0.6; In step S31, the single DoG filter number N is 4, and β=0.065 among the step S35; N 1 = 3; kappa = 0.15. pass Figure 7 It can be seen that the use of the extraction method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com