Device for detecting storage battery through timing discharge under PWM (pulse width modulation) control

A detection device and storage battery technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of poor continuous measurement ability, failure to meet the detection requirements of solar batteries, and inability to continuously test multiple batteries, so as to ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings.

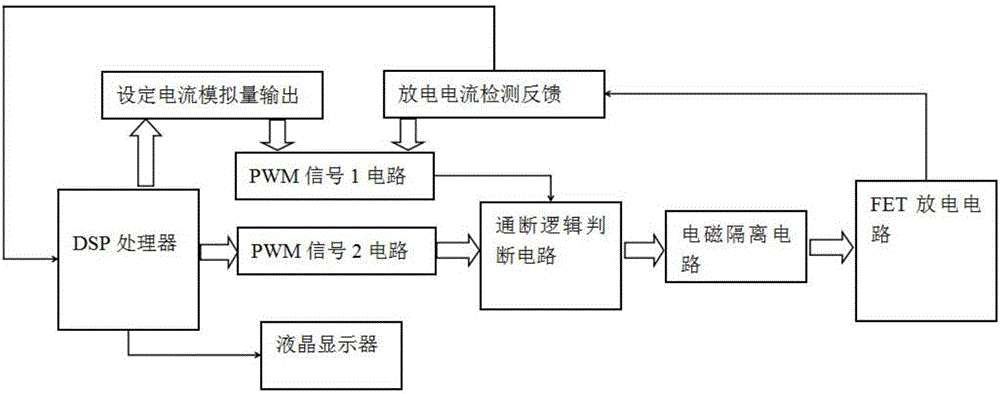

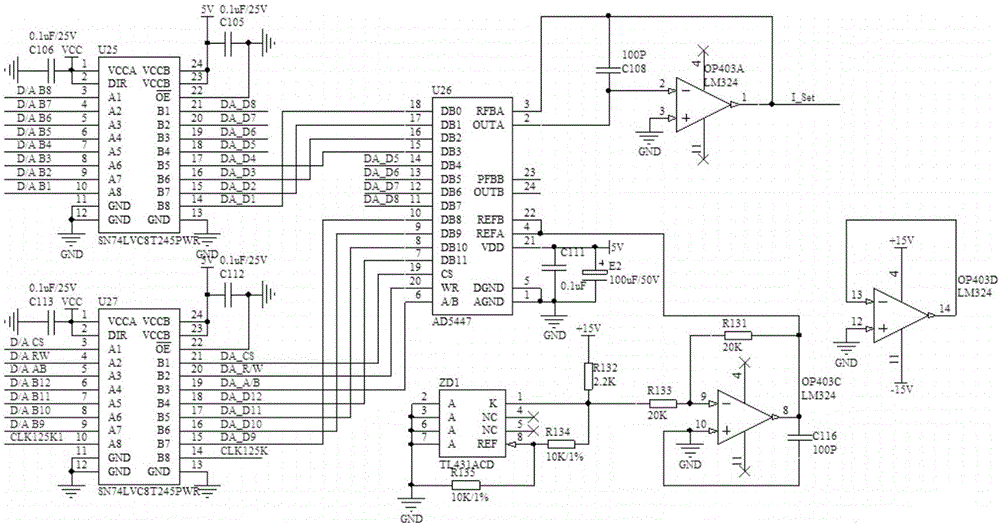

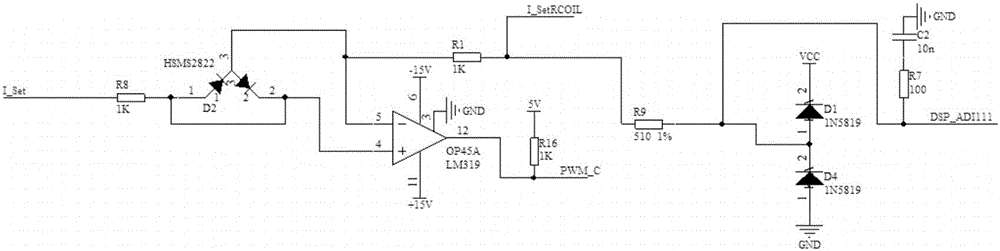

[0027] Such as figure 1 As shown, the working principle of the present invention is as follows: use the DSP28335 chip as the central processing unit, send two kinds of PWM signals, 125KHz and 2MHz, with the unique high-precision PWM output port of the chip, and the PWM signal of 2MHz is sent to the on-off signal circuit through the PWM high-frequency signal circuit. Logic judgment circuit. The DSP28335 chip encodes the discharge current value that needs to be set in the form of multi-channel digital IO output, and outputs the analog quantity to the PWM low-frequency signal circuit in the form of digital-to-analog conversion by setting the current analog quantity output circuit. At the same time, the PWM low-frequency signal circuit Receive the discharge current analog signal fed back by the discharge current detection feedback circuit, compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com