Granular feed granulator

A technology of pellet feed and pellet mill, applied in feed, food science, application and other directions, can solve the problems of poor pelleting stability, inconvenient feed molding, and difficult to control water content in advance, and achieve the effect of improving stability and facilitating molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

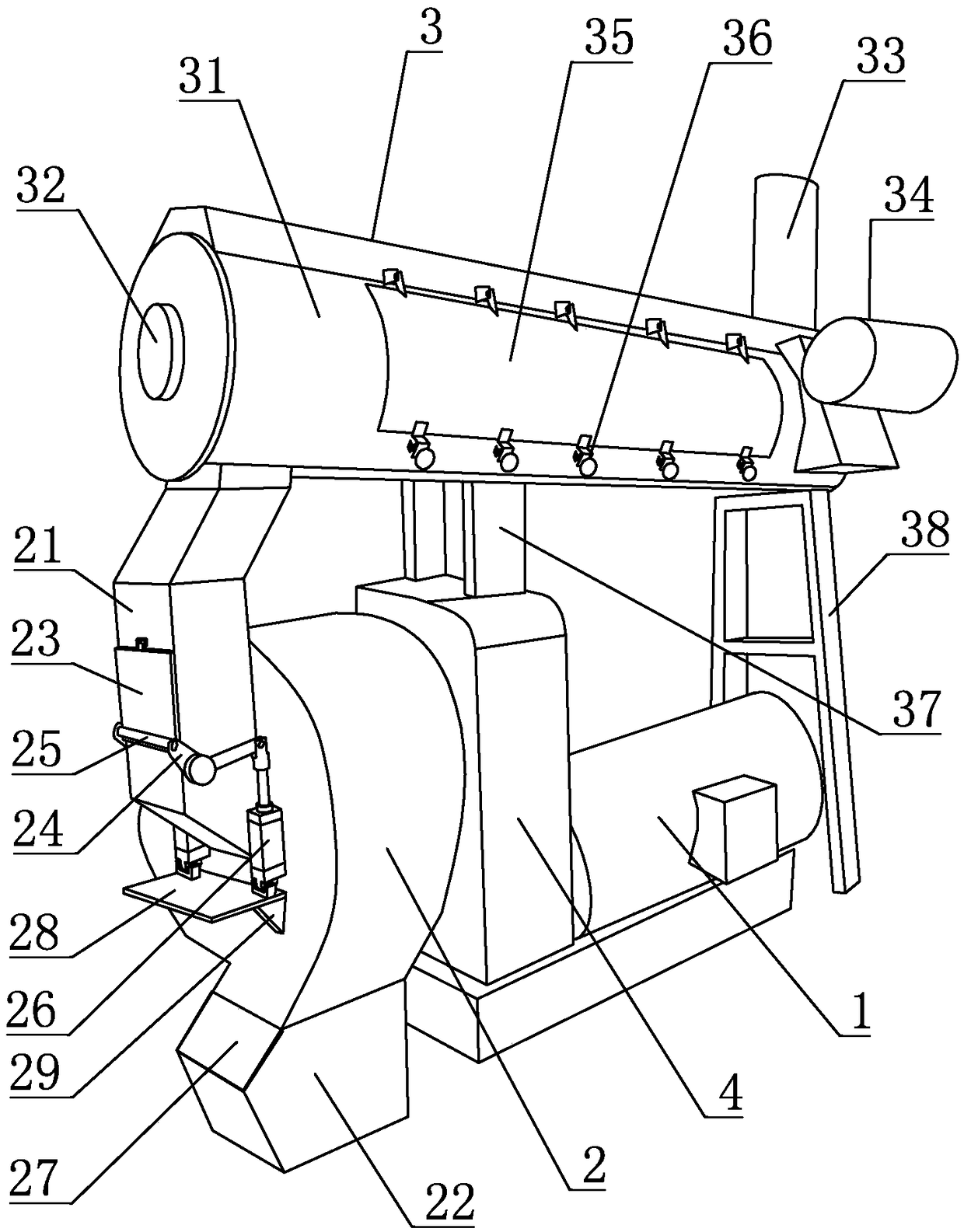

[0013] refer to figure 1 , a granular feed pellet machine of the present invention, comprising a main engine 2 driven by a main motor 1 and a control system, the front side of the main engine 2 is provided with a feeding pipe 21, and the top of the feeding pipe 21 is provided with a feeder 3 , the feeder 3 includes a horizontal feeding tube 31 and a feeding screw 32 installed in the feeding tube 31, the top of the rear end of the feeding tube 31 is connected to the batching bin through a batching pipe 33, and the bottom of the front end is connected to the batching bin through an inclined connection. The tube is connected to the upper end of the feeding pipe 21, and the two ends of the feeding screw 32 are installed on the two ends of the feeding barrel 31 through bearings, and are driven by a feeding motor 34 installed on the rear side of the feeding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com