Sample processing method for determining residual lithium salt on surface of battery shell in flame atomic absorption spectroscopy method

A flame atomic absorption and battery shell technology, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems of non-existent, pre-analytical treatment methods, etc., and achieve the effect of avoiding interference and inhibiting the ionization of lithium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

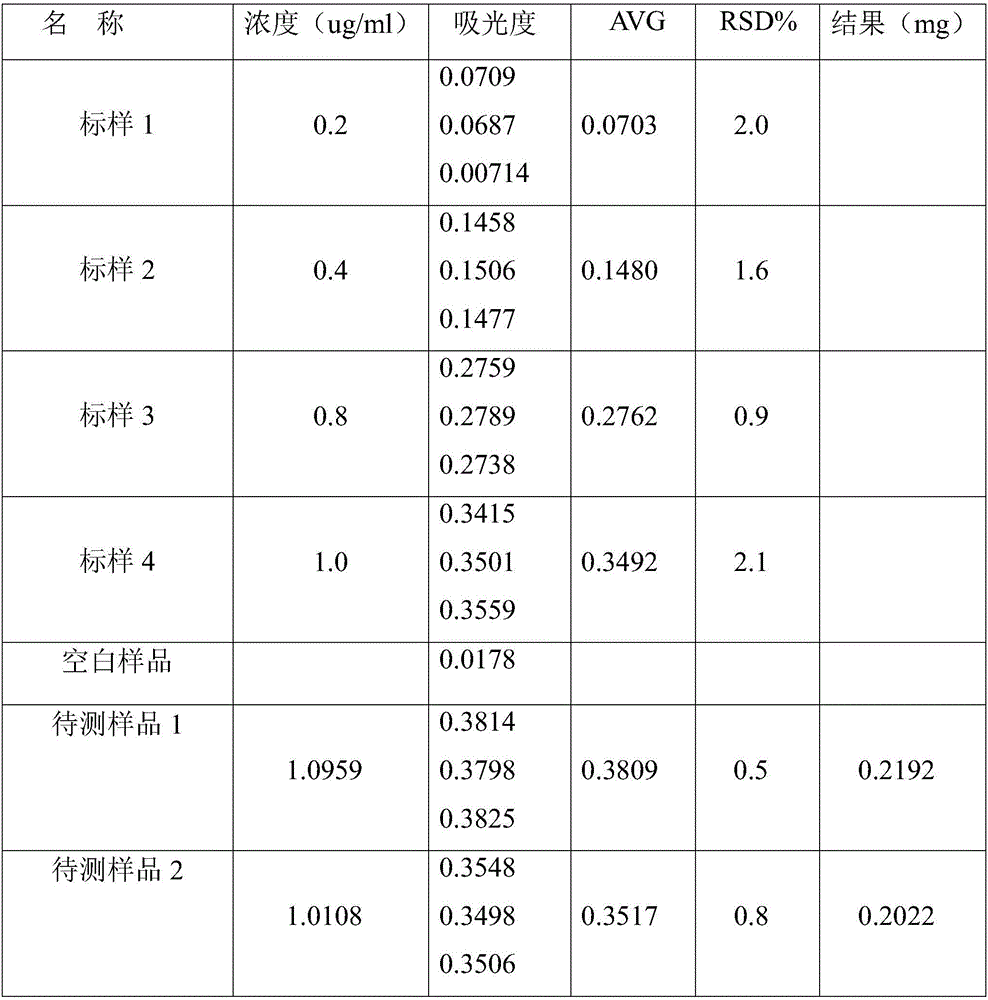

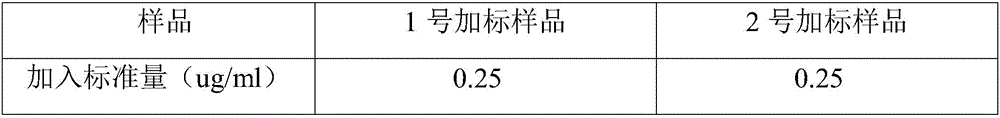

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] A sample processing method for measuring residual lithium salt on the surface of a battery casing by flame atomic absorption method, comprising the following steps:

[0020] (1) Take the unwashed battery filled with electrolyte and place it in a 200ml glass beaker, clean the surface of the battery with dimethyl carbonate, continue to add dimethyl carbonate after cleaning to submerge the whole battery, let it stand for 30 minutes in ventilation, and clean it ultrasonically 10min extraction of lithium salt;

[0021] (2) After ultrasonic cleaning, take out the battery and dry it, then clean the battery shell with nitric acid solution. After cleaning, continue to add nitric acid solution to submerge the whole battery, let it stand for 30 minutes in ventilation, and then ultrasonically clean at 60°C for 10 minutes to extract lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com