Laser ultrasonic detection method and system for temperature field in homogeneous material component

An internal temperature, laser ultrasonic technology, applied in thermometers, thermometers with physical/chemical changes, measuring devices, etc., can solve the problems affecting the temperature field distribution, affecting the accuracy and life of the sensor, large measurement errors, etc., to achieve anti-interference ability. The effect of strong, fast real-time response and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

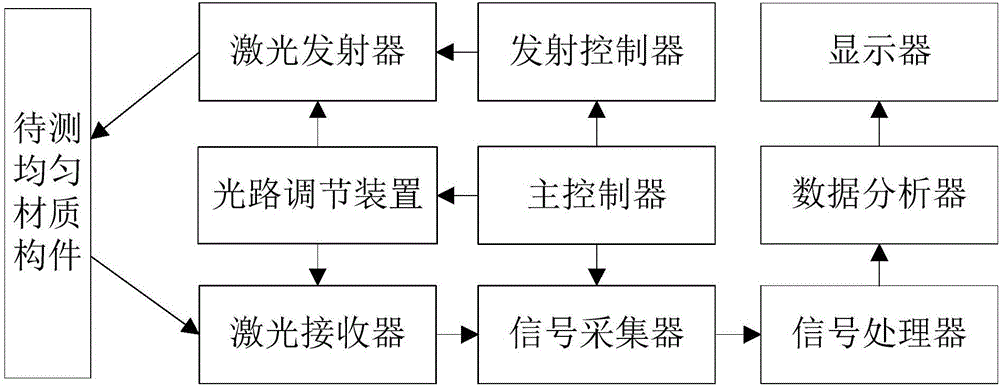

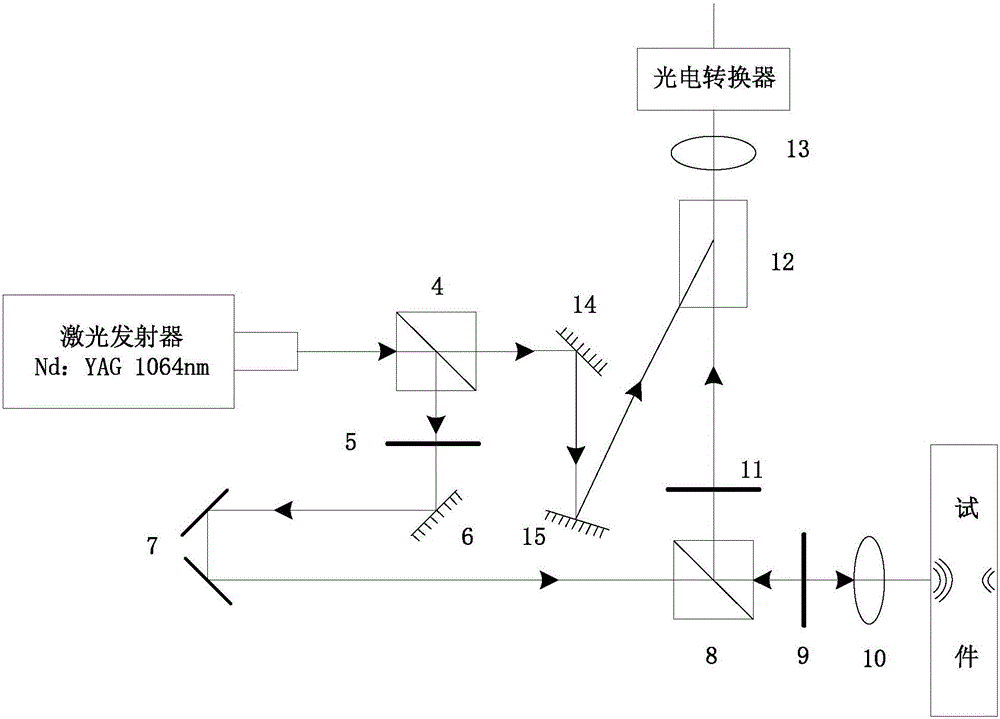

[0050] figure 1 It is a schematic diagram of the principle of the laser ultrasonic detection method. The entire laser ultrasonic temperature measurement system is composed of a laser ultrasonic device (2) and a computer (3). The laser ultrasonic device (2) integrates a laser transmitter, a laser receiver, and an optical path adjustment device. , launch controller, signal collector, main controller and signal processor, the computer (3) is mainly composed of data analyzer and display, and the system is composed of figure 2 shown. When detecting the internal temperature of a heated uniform material component (1), first activate the emission controller through the main controller inside the laser ultrasonic device (2), so that the emission controller controls the laser to emit laser light, and the laser light passes through the optical path adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com