Carbonization kiln capable of heating rural domestic waste indirectly

A technology of domestic waste and heating method, which is applied in lighting and heating equipment, ohmic resistance heating parts, incinerators, etc., can solve the problems that are difficult to form incineration conditions for plant construction, and achieve simple and easy heating methods, precise operation, Fully carbonized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

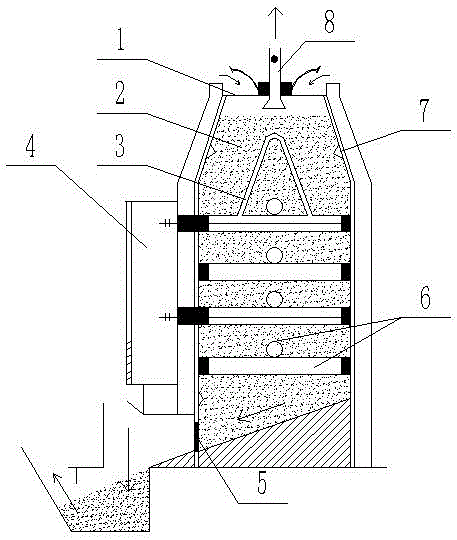

[0024] A carbonization kiln for indirect heating of rural domestic waste, comprising a kiln body 2 , a feed port 1 , a heater 6 , an electric control box 4 , a discharge port 5 and an exhaust port 8 . The upper end of the kiln body 2 is provided with a feed inlet 1; the heaters 6 are staggeredly installed inside the kiln body 2 from top to bottom, and the electric control box 4 is installed outside the kiln body 2; the heating The device 6 is connected with the electric control box 4; the side wall of the bottom of the kiln body 2 is provided with a discharge port 5; the exhaust port 8 is arranged above the kiln body 2. The heater 6 includes a high-temperature-resistant steel pipe and a heating element, and the heating element is installed and fixed in the high-temperature-resistant steel pipe. The heating element is a silicon carbide rod heating element. The indirect heating method carbonization kiln for rural domestic waste also includes a temperature measuring instrument 7...

Embodiment 2

[0027] A carbonization kiln for indirect heating of rural domestic waste, comprising a kiln body 2 , a feed port 1 , a heater 6 , an electric control box 4 , a discharge port 5 and an exhaust port 8 . The upper end of the kiln body 2 is provided with a feed inlet 1; the heaters 6 are staggeredly installed inside the kiln body 2 from top to bottom, and the electric control box 4 is installed outside the kiln body 2; the heating The device 6 is connected with the electric control box 4; the side wall of the bottom of the kiln body 2 is provided with a discharge port 5; the exhaust port 8 is arranged above the kiln body 2. The heater 6 includes a high-temperature-resistant steel pipe and a heating element, and the heating element is installed and fixed in the high-temperature-resistant steel pipe. The heating element is a silicon carbide rod heating element. The indirect heating method carbonization kiln for rural domestic waste also includes a temperature measuring instrument 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com