Oven

An oven and baking cavity technology, applied in the field of ovens, can solve the problems of high failure rate of halogen lamps, inability to withstand high temperature of baking cavity, and dim light color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

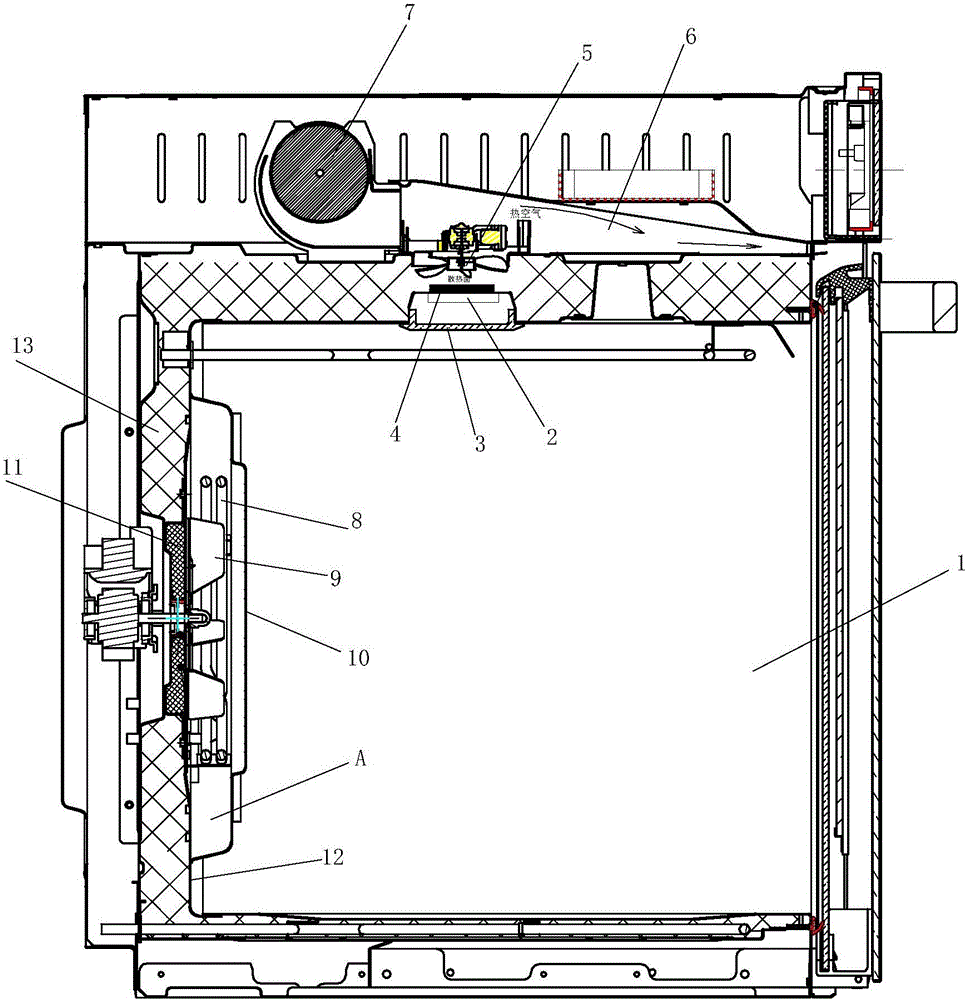

[0019] Such as figure 1 The shown oven includes a baking cavity 1 and a lighting element capable of illuminating the baking cavity 1. The lighting element includes an LED light source 2 and a lampshade 3 covered outside the LED light source. The lampshade 3 is attached to the outside A semiconductor cooling sheet 4 is provided, and the cooling effect surface of the semiconductor cooling sheet 4 is in close contact with the outside of the lampshade.

[0020] The LED light source 2 is an LED light tube, and the LED light source 2 is arranged on the top side inside the lampshade 3; the lighting element is located on the top of the baking cavity 1, and the cold effect surface of the semiconductor cooling plate 4 is close to the outside of the top of the lampshade. The top of the semiconductor cooling sheet 4 is provided with a cooling fan 5 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com