Lubricating grease conveying device with little residual oil amount

A technology of conveying device and lubricating grease, which is applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve the problems of high working pressure, unfavorable saving and environmental protection, and high labor intensity of pump source conveying vehicles, and achieve the solution of oil supply and Conveying problems, simple structure, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

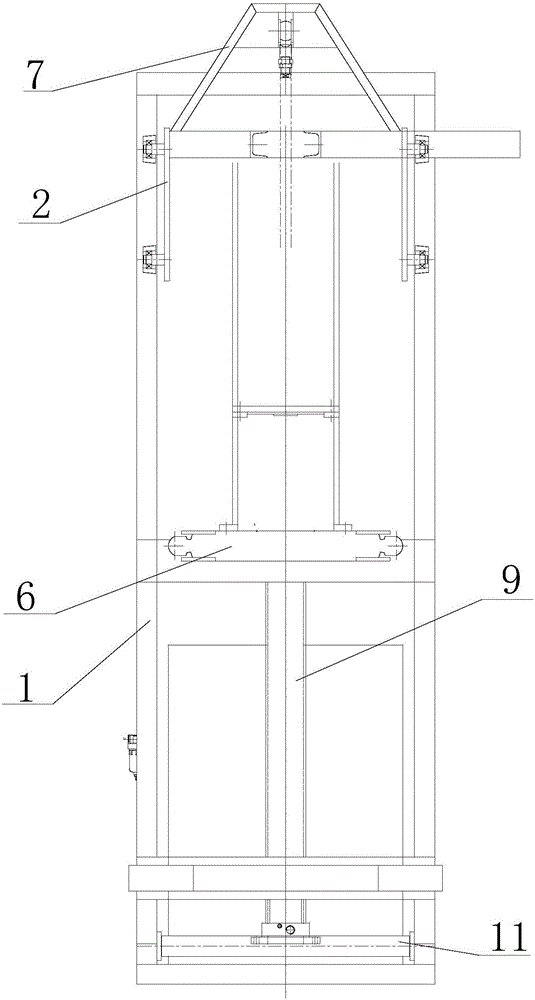

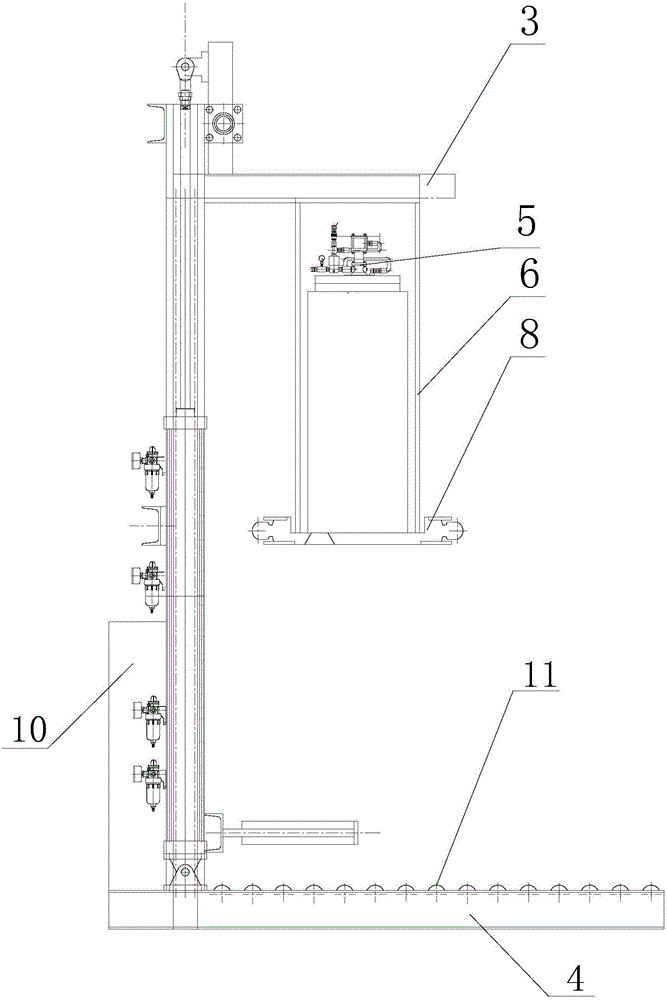

[0020] see Figure 1-2 , a lubricating grease conveying device with less residual oil, comprising a door-shaped frame 1, a pulley 2, a flange seat cylinder 9 and a high-pressure pneumatic air pump 5, a pulley 2 is arranged inside the door-shaped frame 1, and the pulley 2 is connected to a cantilever 3, the other end of the cantilever 3 is provided with a hanger 6, the bottom of the hanger 6 is equipped with an oil suction plate 8, and an oil suction nozzle is arranged on the oil suction plate 8, and one end of the oil suction nozzle is connected with the oil inlet of the high-pressure pneumatic air pump 5, The oil outlet of the high-pressure pneumatic air pump 5 is connected to one end of the oil pipe, and the other end of the oil pipe is connected to the first oil pipe joint provided on the hanger 6. The first oil pipe joint is connected to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com