Quasi-free piston internal combustion engine

An internal combustion engine and piston technology, which is applied in the field of quasi-free piston internal combustion engine, can solve the problems of large inertial force, large mass of reciprocating moving parts, and strong vibration of the unit, and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

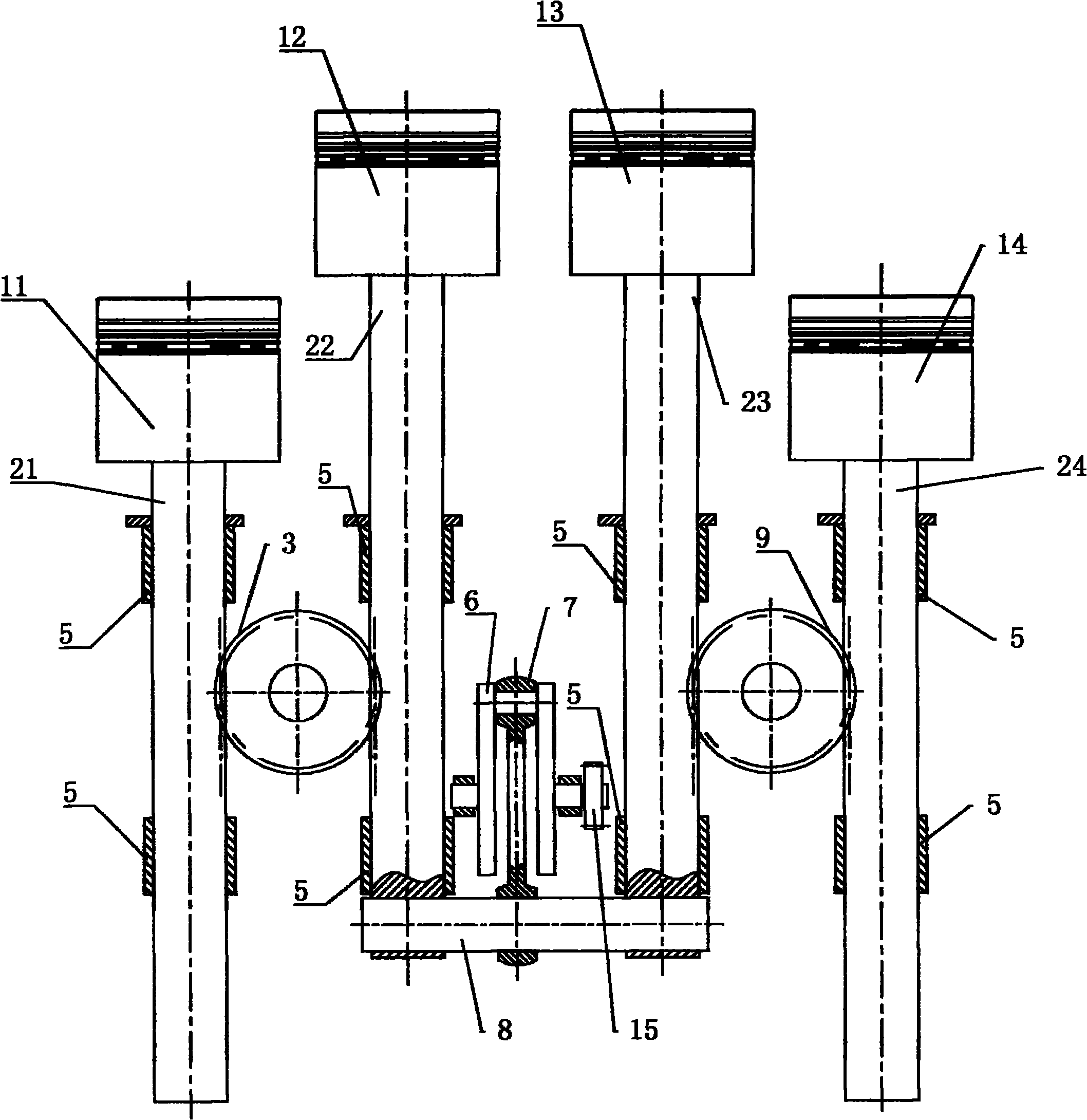

Embodiment 1

[0023] Such as figure 1 Shown, a kind of quasi-free-piston internal combustion engine of four-cylinder four-stroke, it comprises the first piston 11, the second piston 12, the third piston 13 and the fourth piston 14 that are arranged in parallel from left to right, and described four pistons all Installed in their respective cylinders. The four pistons are sequentially fixedly connected with a first power rod 21, a second power rod 22, a third power rod 23 and a fourth power rod 24, and the four power rods are respectively restrained in the linear bearing 5, and the linear The bearing 5 is arranged on the cylinder block, and the linear bearing 5 acts as a guide. For this purpose, other structures can also be used to linearly constrain the four power rods on the cylinder block.

[0024] A linkage shaft 8 is installed between the second power rod 22 and the third power rod 23, gear teeth are arranged on the surfaces adjacent to the first power rod 21 and the second power rod 2...

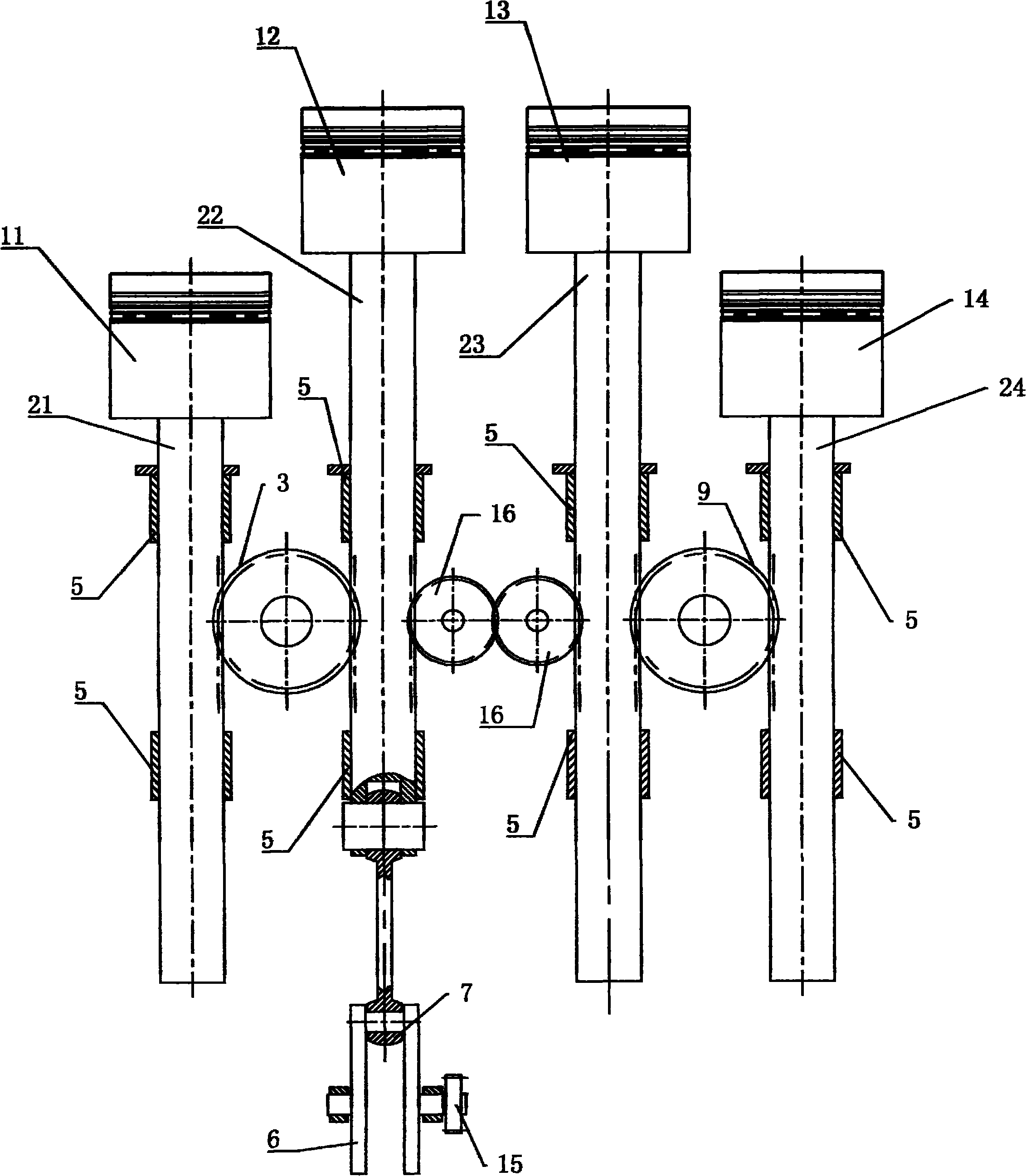

Embodiment 2

[0029] figure 2 What is shown is also a quasi-free piston internal combustion engine with four cylinders and four strokes. Its structure is basically the same as that of Embodiment 1. Linkage device, the same-direction linkage device includes a pair of interlocking gears 16 that are engaged with each other and rotatably mounted on the cylinder block of the internal combustion engine, and the opposite sides of the two adjacent power rods that move in the same direction are respectively provided with wheels Teeth, said gear teeth respectively mesh with a corresponding linkage gear. At this time, one end of the connecting rod 7 is hinged to a connecting rod journal of the crankshaft 6 , and the other end is hinged to the end of one of the power rods, such as the second power rod 22 .

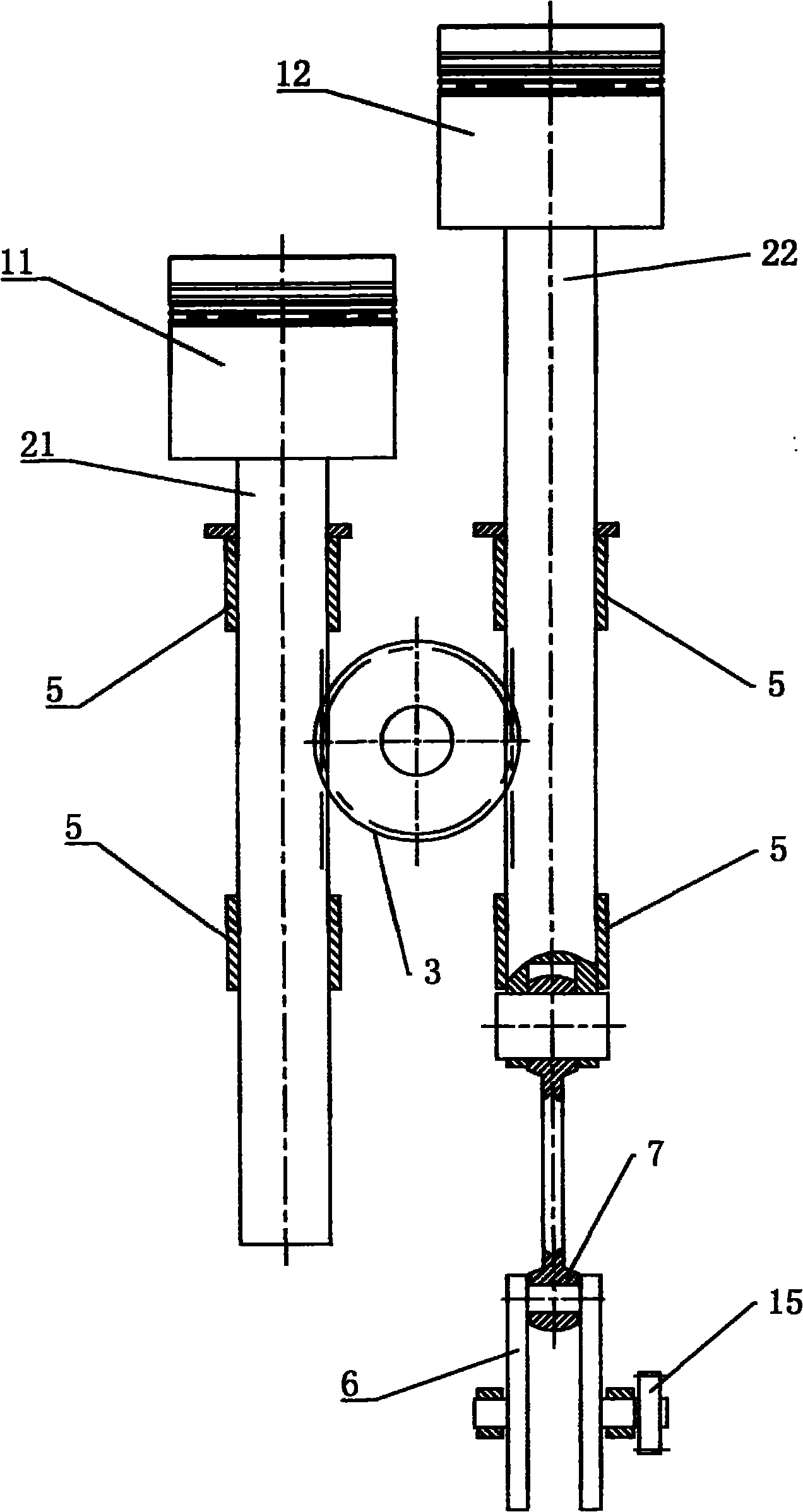

Embodiment 3

[0031] Such as image 3 As shown, a quasi-free piston internal combustion engine with two cylinders and two strokes, its structure is actually a simplified version of embodiment 2, and only two pistons moving in opposite directions and the necessary structure for ensuring operation thereof have been selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com