Antifreeze screw pump screw to increase the flow rate of liquid in the pump

A technology for adding pumps and screw pumps, applied in the direction of liquid fuel engines, pumps, pump components, etc., can solve the problems of difficult suction and discharge, maintaining the temperature of the suction and discharge liquid of the screw pump, and damage to the pump body of the screw pump, and achieve the effect of avoiding the solidification of the liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

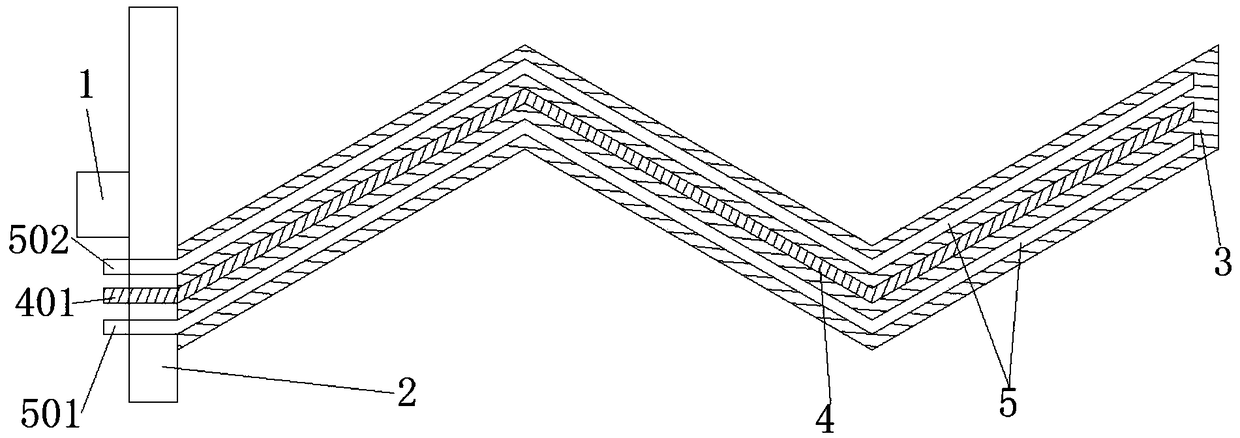

[0020] like figure 1 As shown, the antifreeze screw pump screw of the present invention that increases the liquid flow rate in the pump includes a cardan shaft 1, a cardan shaft seat 2 and a screw rod 3 connected in sequence, extending from the joint of the cardan shaft seat 2 and the screw rod 3 to the screw rod 3 The diameter of the hole is 1 / 6 of the screw diameter, and the heating wire 4 is arranged in the hole, and the heating wire 4 passes through the universal shaft seat 2 and connects with the electric heating interface 401 on the universal shaft seat 2 . By setting the electric heating wire in the screw, when the ambient temperature is too low, turn on the power supply of the electric heating interface, and the electric heating wire works to heat the screw, thereby heating the liquid in the screw pump and ensuring the temperature of the liquid. An insulating and heat-conducting rubber is arranged between the heating wire 4 and the screw 3 . Because the heating wire i...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that the two hollow tube holes 5 are connected to each other, and the two hollow tube holes 5 pass through the cardan shaft seat 2 and connect with the water inlet 501 and the water outlet 502 respectively. connect. The auxiliary heating or cooling of the pump body is realized by injecting water into the hollow tube hole. The two hollow tube holes 5 pass through the universal shaft seat 2 and are respectively connected to the water inlet 501 and the water outlet 502 , wherein one hollow tube hole 5 is connected to the water inlet 501 and the other hollow tube hole 5 is connected to the water outlet 502 . Ensure that the flow rate at the water inlet and outlet is relatively stable, and the system stability is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com