A booster pump for food high pressure sterilization equipment

A high-pressure sterilization, booster pump technology, applied in food preservation, mechanical equipment, application and other directions, can solve problems such as large limitations, and achieve the effect of improving the inactivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

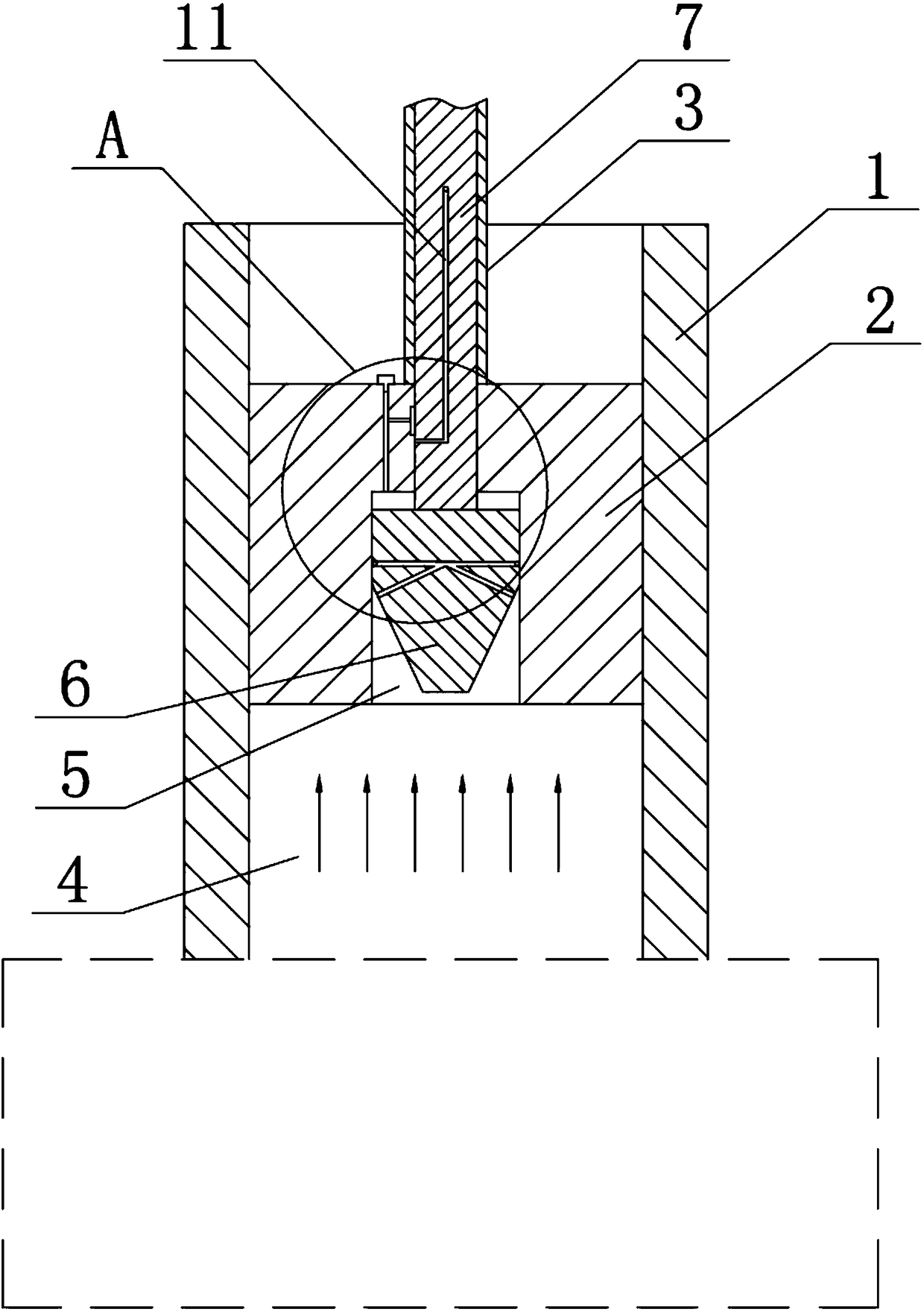

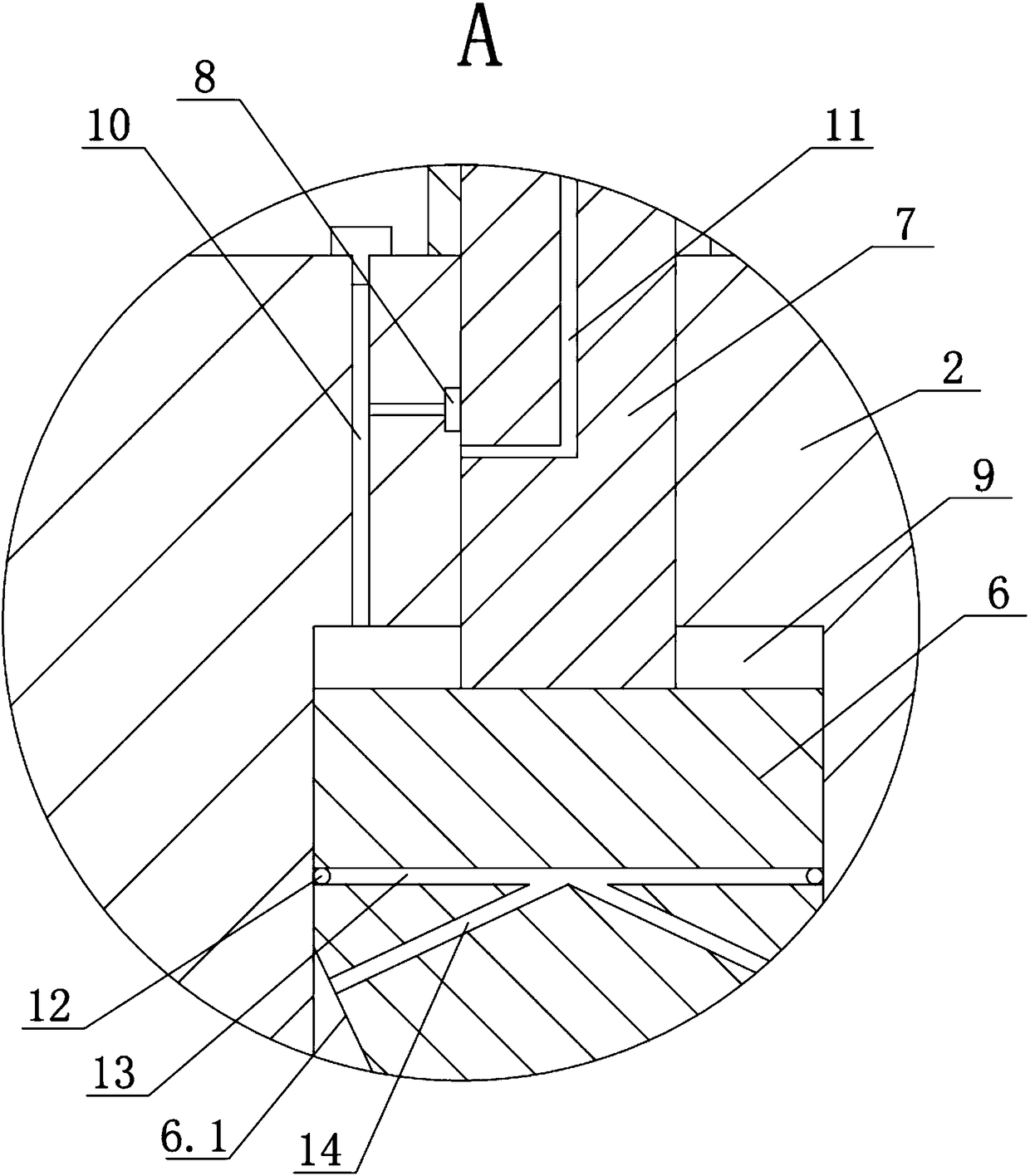

[0014] The invention provides a booster pump for food high-pressure sterilization equipment, which includes a pump body 1, a piston 2 and a piston rod 3 arranged in the pump body 1, the piston 2 is slidingly fitted with the pump body 1, and the piston 2 A working chamber 4 is formed between the lower end face and the inner side wall of the pump body 1, the piston rod 3 is located on the side of the piston 2 away from the working chamber 4, the lower end of the piston rod 3 is fixed to the piston 2, and it is characterized in that: On the lower end surface of the piston 2 near the working chamber 4, an accommodating groove 5 is concavely formed in the axial direction. A sub-piston block 6 is arranged in the accommodating groove 5. Between the outer wall of the sub-piston block 6 and the inner wall of the accommodating groove 5 The piston rod 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com