Exhausting ducts of naturally aspirated engine

An exhaust channel, naturally aspirated technology, applied in engine components, machines/engines, exhaust devices, etc., can solve problems such as deteriorating the performance of naturally aspirated engines, and achieve the effect of reducing the residual amount of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

[0033] The above, below, left and right of the present invention are all referred to as figure 1 prevail.

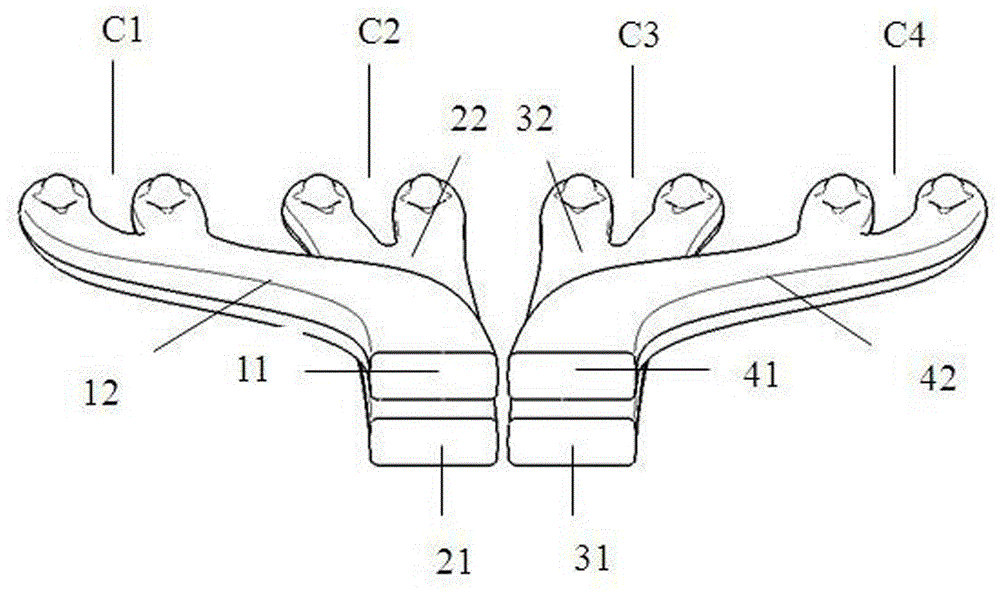

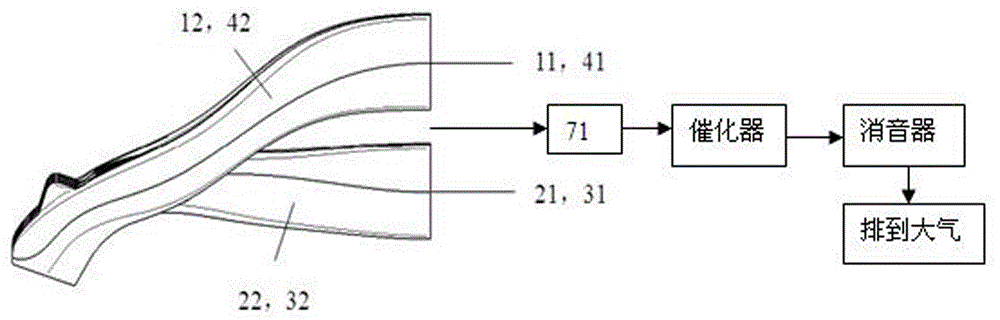

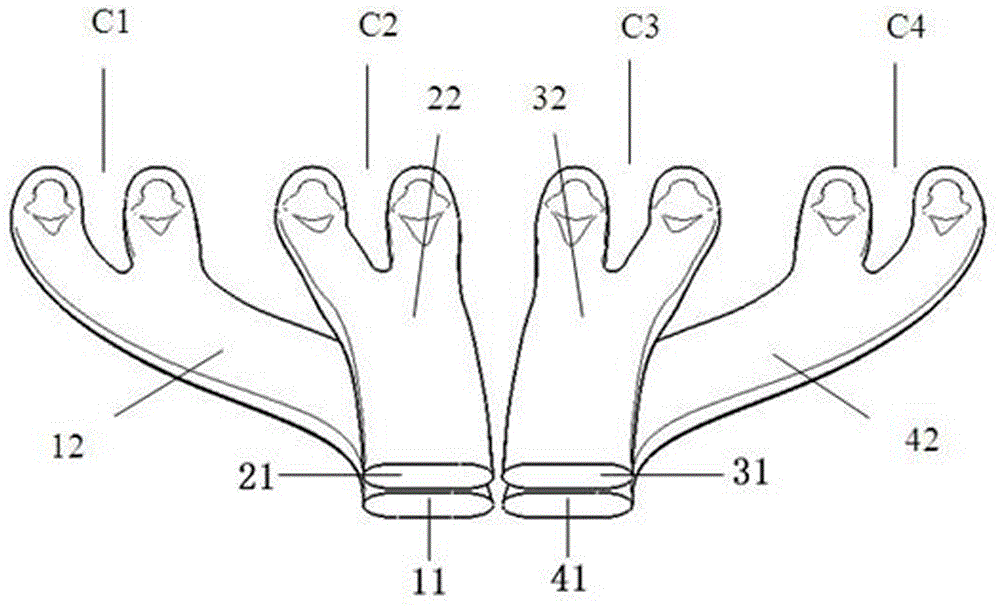

[0034] The invention is applicable to four-cylinder and three-cylinder naturally aspirated engines. Take a naturally aspirated engine with four cylinders as an example, such as figure 1 As shown, an exhaust passage of a naturally aspirated engine includes: the first exhaust passage 12 of the first cylinder C1, the second exhaust passage 22 of the second cylinder C2, and the third exhaust passage of the third cylinder C3 32, the fourth exhaust passage 42 of the fourth cylinder C4, the exhaust passages are independent and not connected to each other.

[0035] Such as figure 1 and image 3 As shown, for a four-cylinder naturally aspirated engine, according to the upper and lower cooling water jackets insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com