Method and structure for connection of heat preservation system and wall of building

A technology for building thermal insulation and walls, applied in building structures, building components, thermal insulation, etc., can solve problems such as loss of compression and anchoring effect of expansion bolts, broken plates around the pressed sheet, and easy fires, etc., so as to save materials and labor , Pollution reduction, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

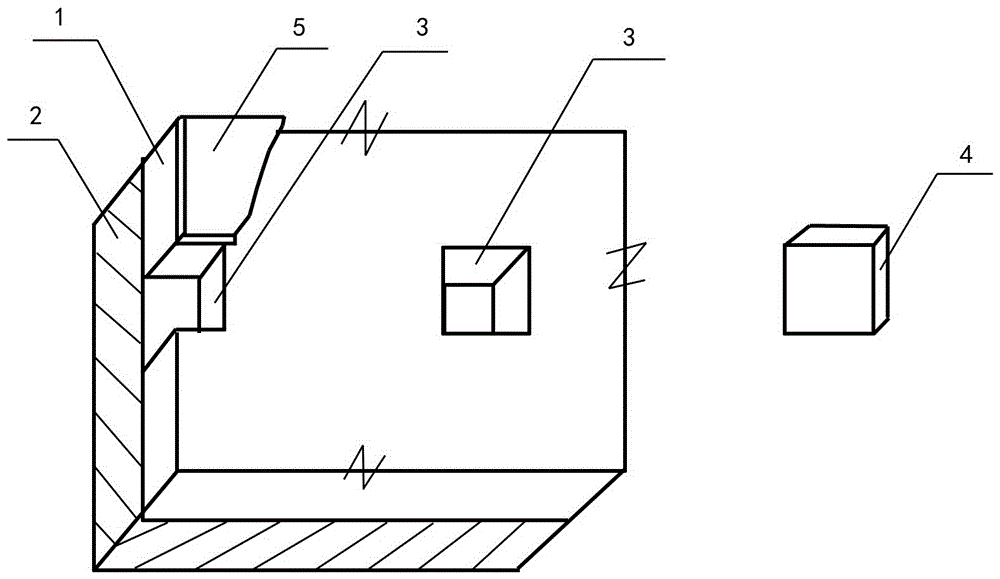

Embodiment 1

[0031] The blocking board 4 is a wooden board that has been treated with anticorrosion and fire prevention. Fill the blocking board 4 into the window hole 3, and fix the blocking board 4 on the wall with expansion bolts or a nail gun; or fix the blocking board 4 on the wall with an adhesive . The protective layer laid on the outside of the thermal insulation layer is fixed by means of the blocking plate 4 again.

Embodiment 2

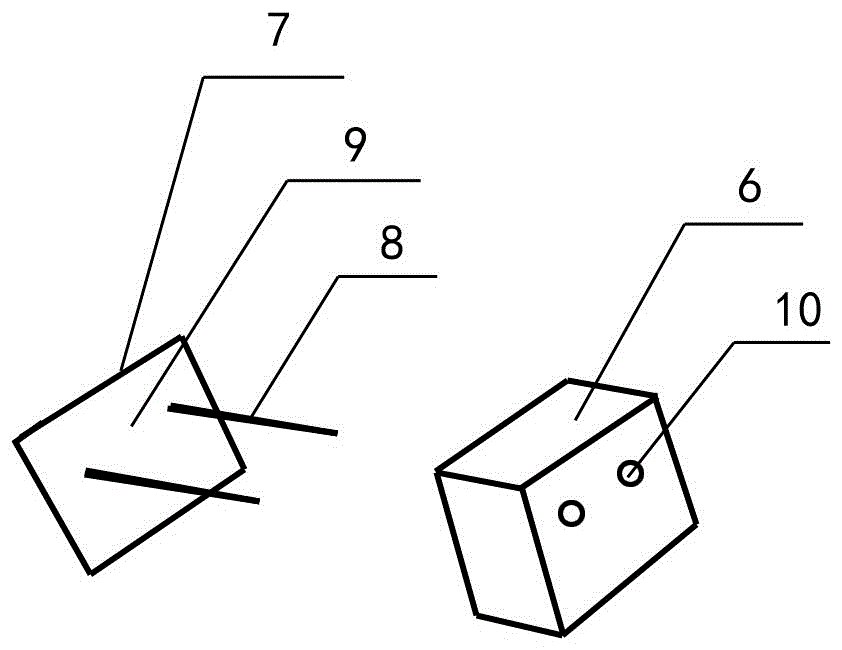

[0033] Connect one end of the steel wire or bolt 8 to the expanded metal 9, and the two together form a connecting piece 7, or use a steel wire, a bolt, or another part alone as the connecting piece 7, and the other end of the steel wire or bolt 8 passes through a small plate 6 hole 10, and exposed a certain working length outside the small plate 6, combined into a blocking plate 4. After smearing high-strength cement mortar on the expanded metal 9 of the blocking board 4, the expanded metal 9 of the blocking board 4 faces the wall, the blocking board 4 is filled into the window hole 3, and the wall is squeezed and compacted so that the cement After the mortar is hardened, it is firmly combined with the wall surface and the steel mesh. Lay steel wire mesh on the outer side of the insulation layer, connect and position with steel wire or bolt 8, apply cement mortar on the steel wire mesh to form a cement mortar steel wire mesh protective layer; layer. Or replace the connectin...

Embodiment 3

[0035] Apply thermal insulation mortar to the wall as an insulation layer. First use glue or (and) mechanical method to fix the blocking board 4 on the wall, and make the surface of the blocking board 4 facing the outside of the wall basically on the same plane, the distance between this plane and the wall is equal to the thickness of the insulation layer, The surface is covered with thermal insulation mortar as the thermal insulation layer, and a protective layer is installed outside the thermal insulation layer, and the protective layer is connected and fixed with the blocking plate 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com