Control method of head-to-tail differential burning of x80 pipeline steel slab

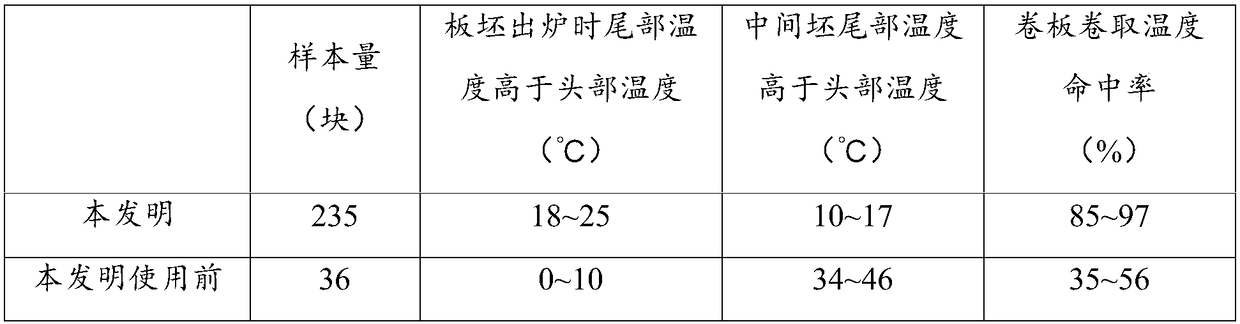

A control method and technology for steel slabs, which are used in heat treatment process control, manufacturing tools, furnaces, etc., can solve the problems of low coiling temperature hit rate and large temperature drop at the tail of the intermediate billet, improve product structure, increase economic benefits, The effect of enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

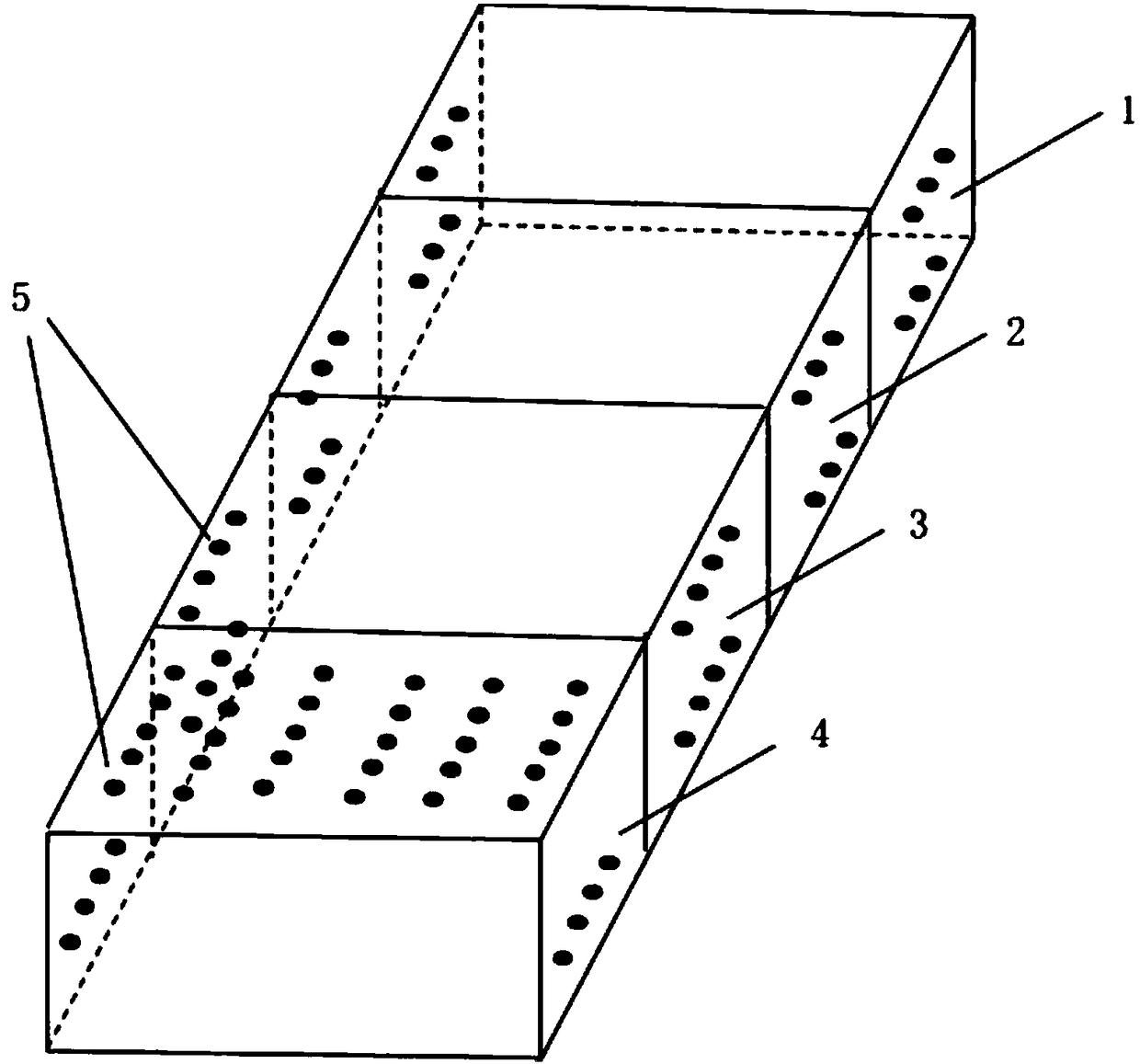

[0023] The specifications of the X80 pipeline steel slab are: 10920mm×1700mm×230mm (length×width×thickness), and the slab is cold-packed. The total heating time is 180 to 240 minutes, the soaking time is 30 to 60 minutes, and the furnace temperature is 1180±20°C. Control the opening degree of the burners in each heating section of the heating furnace: the opening degrees of the flame regulating burners 5 on the left and right sides of the preheating section 1 are both 90 degrees; the opening degrees of the flame regulating burners 5 on the left and right sides of the heating section 2 are respectively 60 degrees and 90 degrees; the opening degrees of the flame regulating burners 5 on the left and right sides of the second heating section 3 are 60 degrees and 90 degrees respectively; the opening degrees of the flame regulating burners 5 on the left and right sides of the heating section 4 are respectively 60 degrees and 90 degrees , The opening degree of the heating flat flame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com