A method for manufacturing aluminum alloy manipulator rail beam hollow profile

A technology of mechanical arms and hollow profiles, which is applied in the field of aluminum alloy profiles, can solve the problems of low production efficiency of hollow track girders, and achieve the effect of reducing strength weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for manufacturing an aluminum alloy manipulator track girder hollow profile, the steps are as follows:

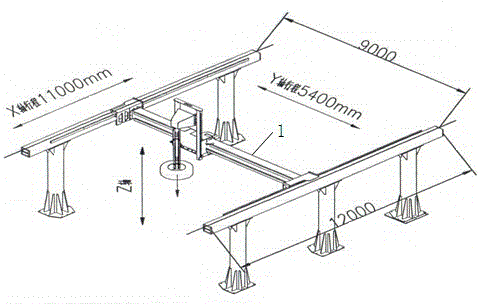

[0039] 1. According to the current working state of the steel structure track girder, the steel girder will not deform under the condition of bearing 1000 kg of moving gravity, and it will work stably and normally. For the working state of the steel beam, see figure 1 ;

[0040]2. Select 6061 aluminum alloy as the aluminum alloy instead of steel alloy, cast aluminum alloy round ingot, the specification of 6061 alloy round ingot is Ф594mm×7000mm, the mass percentage of Si in aluminum alloy ingot is 0.75%, Fe is 0.12%, Cu is 0.20%, Mn is 0.10%, Mg is 1.15%, Cr is 0.1%, Zn is 0.10%, Ti is 0.10%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the rest is Al, casting specification: Ф594 ×7000mm, the ingot wagon to Ф580±2mm, the cut-off size is 1250mm, the Ф580±2mm×1250mm ingot is homogeneously treated, the heating temperature is 560±5°C, and the heat preservat...

Embodiment 2

[0048] For step 2, the aluminum alloy to be cast is 6061 aluminum alloy round ingot with a specification of Ф580±2mm×1250mm. When smelting No. 6 aluminum alloy round ingot, it is required to calculate ingredients, liquid slag removal, degassing, and filter when casting. The calculation of ingredients is based on the center line of step 2 to ensure that the composition of the ingot is controlled within the standard range; slag removal after melting, once after refining in the smelting furnace, once after refining in the holding furnace; once after refining in the melting furnace The gas and holding furnace are degassed once after refining, and the holding furnace is refined and degassed again. The cast aluminum alloy ingot is a No. 6 aluminum alloy round ingot. The specifications are Ф594mm×7000mm No. 6 aluminum alloy round ingot wagon body, head, tail, low magnification, chemical composition, and after the low magnification and chemical composition are qualified, the wool is cu...

Embodiment 3

[0050] For step 5, the heating temperature is 540°C, quickly put into the extrusion cylinder, the extrusion speed is 2.5m / min, the quenching temperature is guaranteed to be above 520°C, the air volume is 80% + water mist cooling, the quenching speed is 330-350°C, other steps and Parameters are the same as in Example 1. The ingot is heated at high temperature and extruded at a slow speed to ensure the welding quality of the hollow profile and reduce the size of the defective welding at the extrusion head. When the ingot is heated to 540°C and the extrusion speed drops to 2.5m / min, the extrusion Press quenching cooling: air cooling and water cooling at the same time, air cooling and water cooling at the same time, increase the quenching speed and improve the mechanical properties.

[0051] The mechanical properties of the aluminum alloy mechanical arm track girder hollow profile produced by specific examples 1-3 are 279-330MPa in tensile strength, 258-290MPa in yield strength, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com